Method for preparing high cis-polyisoprene through utilizing gas phase polymerization, and catalyst

A polyisoprene, gas-phase polymerization technology, applied in the field of gas-phase polymerization of high cis-1,4-polyisoprene, can solve problems affecting rubber processing and application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

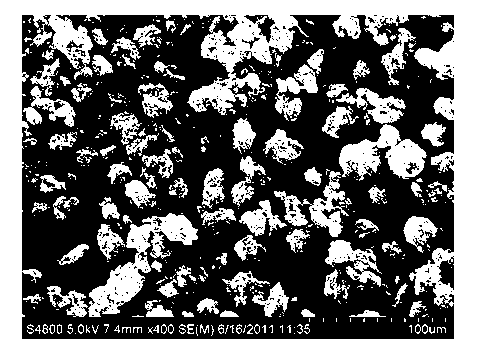

Image

Examples

Embodiment 1

[0032] (1) Catalyst preparation

[0033] The catalyst consists of Nd(naph) 3 、Al(i-Bu) 3 , AlEtCl 2 , silica with a particle size in the range of 10-250 μm, and nano-particle carbon black with a particle size in the range of 5-300 nm. The solvent used in the catalyst preparation process is n-hexane, of which the first component Nd (naph) 3 The amount is 1.2mmol, the second component Al(i-Bu) 3 The amount is 96mmol, the third component AlEtCl 2 The amount of is 7.2mmol, and the amount of the fourth component silicon dioxide is 1.2g, and the amount of the fifth component carbon black is 2.4g, makes powdery catalyst A 1 10.31g.

[0034] (2) Isoprene gas phase polymerization process

[0035] In the purified stirred reactor, add the powder catalyst A prepared above under the protection of nitrogen 1 10.31 g, evacuated nitrogen, started stirring, introduced isoprene gas, reacted at 70°C for 1 hour under 0.1 MPa pressure, and dried after post-treatment to obtain 2399.2 g...

Embodiment 2

[0043] (1) Catalyst preparation

[0044] The catalyst consists of Nd(OiPr) 3 、Al(i-Bu) 3 、Al 2 Et 3 Cl 3 , magnesium chloride with a particle size range of 10-250 μm and nano-particle silicon dioxide with a particle size range of 5-300 nm. The solvent used in the catalyst preparation process is toluene, wherein the first component Nd(OiPr ) 3 The amount is 1.0mmol, the second component Al(i-Bu) 3 The amount is 30.0mmol, the third component Al 2 Et 3 Cl 3 The amount of is 1.0mmol, the amount of the fourth component magnesium chloride is 50.0g, the amount of the fifth component silicon dioxide is 50.0g, and the powdery catalyst B is prepared 1 107.2g.

[0045] (2) Isoprene gas phase polymerization process

[0046] In the purified stirred reactor, add the powder catalyst B prepared above under the protection of nitrogen 1 107.2g, evacuated nitrogen, started stirring, introduced isoprene gas, under 0.1MPa pressure, reacted at 60°C for 1 hour, after post-treatment and...

Embodiment 3

[0054] (1) Catalyst preparation

[0055] The catalyst consists of Nd(P 204 ) 3 、Al(Me) 2 H, Al 2 Et 3 Cl 3 , Alumina with a particle size range of 10-250 μm

[0056] It consists of five components such as nanoparticle talc powder with a particle size range of 5-300nm. The solvent used in the catalyst preparation process is toluene, wherein the first component Nd(P 204 ) 3 The amount is 1.0mmol, the second component Al(Me) 2 The amount of H is 100.0mmol, the third component Al 2 Et 3 Cl 3 The amount of is 8.0mmol, the amount of the fourth component alumina is 20.5g, the amount of the fifth component talcum powder is 72.4g, and the obtained powdery catalyst C 1 102.3 g.

[0057] (2) Isoprene gas phase polymerization process

[0058] In the purified stirred reactor, add the powder catalyst C prepared above under the protection of nitrogen. 1 102.3g, evacuate nitrogen, start stirring, feed isoprene gas, react at 50°C for 1 hour under 0.1MPa pressure, and dry after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com