Poly-terephthalic acid butanediol ester (PBT)/ poly-terephthaloyl hexamethylenediamine (PA6T) alloy material capable of enhancing inflaming retarding and production method thereof

A technology of polybutylene terephthalate and polyhexamethylene terephthalate, applied in the field of organic polymer materials, can solve problems such as poor glow wire performance, and achieve high glow wire performance and mechanical properties , the production process is simple, the effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

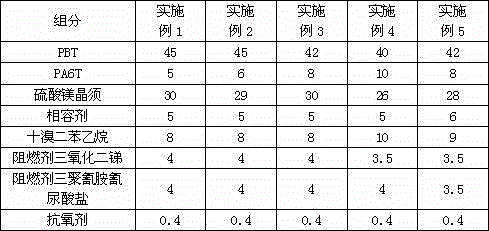

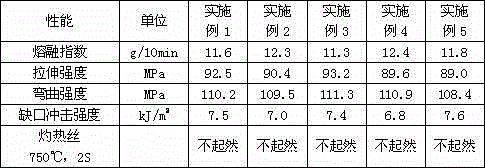

[0010] Below in conjunction with embodiment the present invention will be further described:

[0011] First, dry the weighed polybutylene terephthalate (PBT) and polyhexamethylene terephthalamide (PA6T) at 120°C for 4 hours. Pour the dried polybutylene terephthalate and polyhexamethylene terephthalamide into a high-speed mixer and stir at a low speed. While stirring, put all components except the magnesium sulfate whiskers into the high-speed mixer according to the ratio in Table 1 and mix for 10 minutes. It is then blended and extruded through a twin-screw extruder. Magnesium sulphate whiskers were forced in via side feed. The blending processing temperature is 245-260°C, the screw speed is 350r / min, and the product is extruded, water-cooled, and pelletized. The produced material was dried at 120°C for 4 hours, and then standard mechanical property test specimens were prepared on an injection molding machine. The injection pressure is 60-90Mpa, the barrel temperature is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com