Selective hydrodesulfurization process method of poor-quality gasoline and device

A technology for hydrodesulfurization and inferior gasoline, applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve problems such as low product yield, and achieve the effect of low hydrogen consumption and increased octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

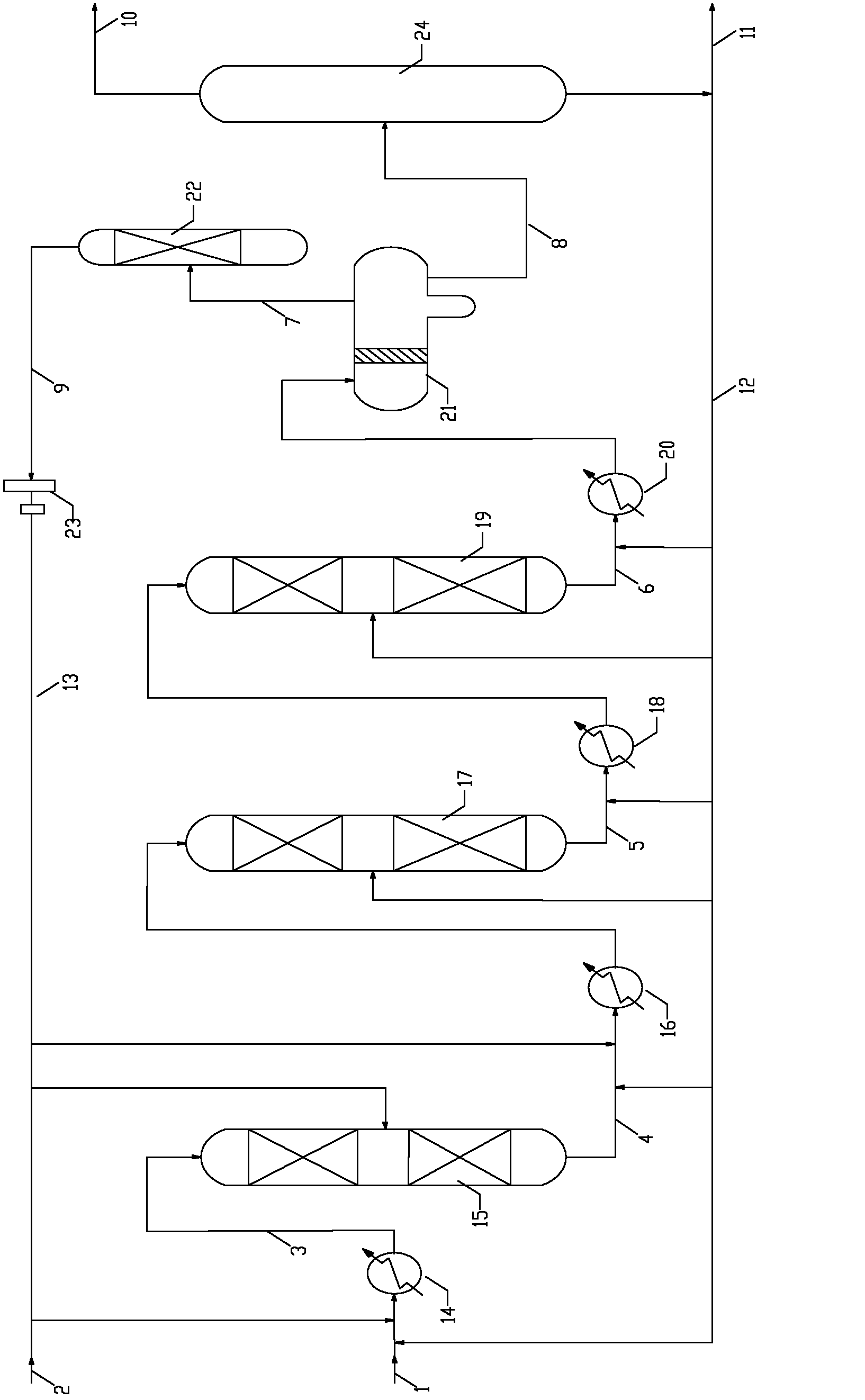

Method used

Image

Examples

Embodiment 1

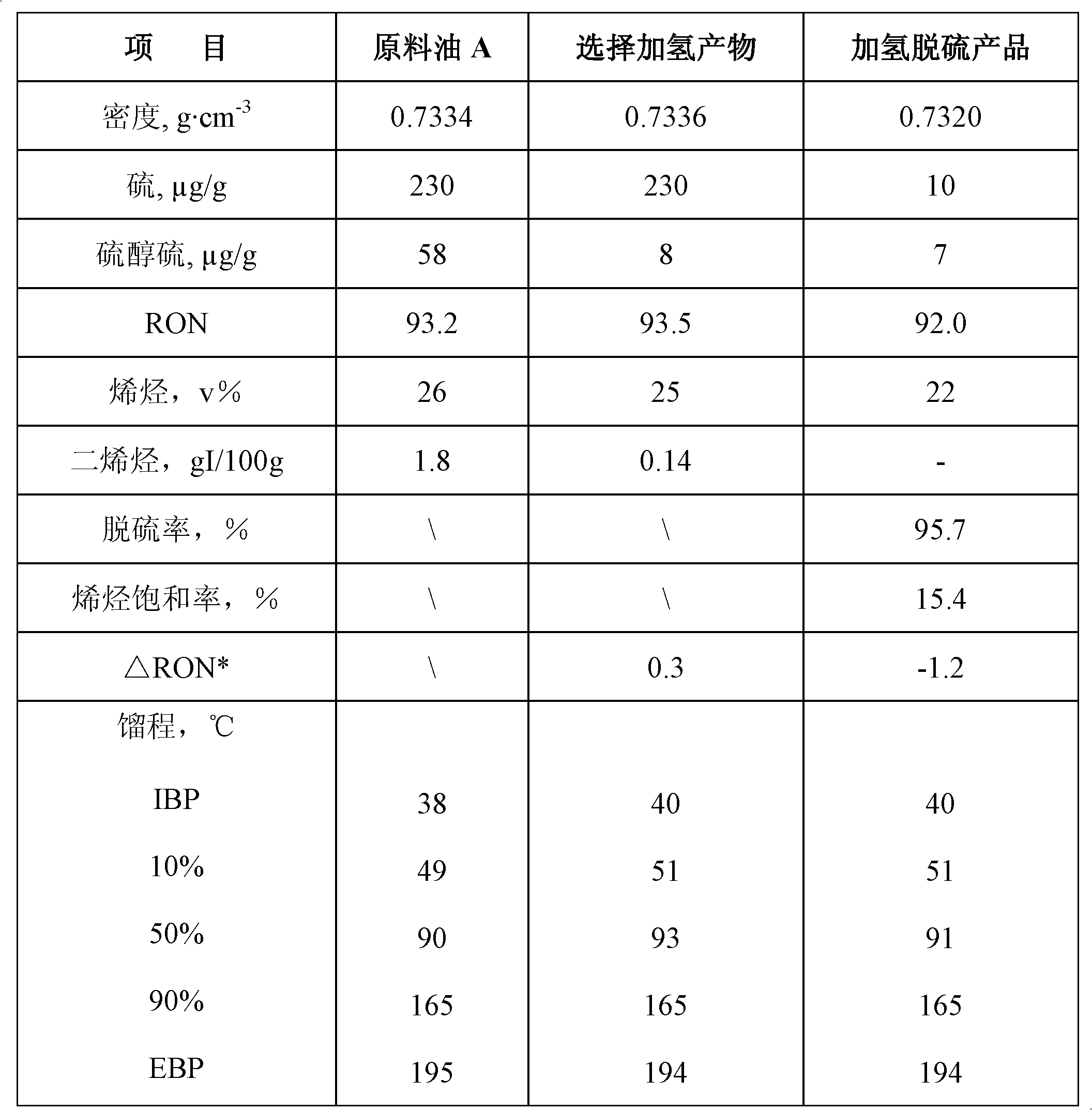

[0056] Selective hydrogenation catalyst HDDO-100 and selective hydrodesulfurization catalyst HDOS-200 were installed in a 200ml small-scale hydrogenation evaluation device with two hydrogenation reactors in series, and the raw material oil A was subjected to selective hydrodesulfurization treatment.

[0057] The selective hydrogenation reaction conditions for HDDO-100 catalyst are as follows:

[0058] Temperature = 135°C

[0059] Pressure = 2.2MPa

[0060] Liquid space velocity = 3h -1

[0061] Hydrogen oil volume ratio = 10v / v

[0062] The selective hydrodesulfurization reaction conditions for HDOS-200 catalyst are as follows:

[0063] Temperature = 250°C

[0064] Pressure = 2.0MPa

[0065] Liquid space velocity = 3h -1

[0066] Hydrogen oil volume ratio = 400v / v

[0067] The properties of the intermediate product in the hydrotreating process of feedstock oil A and the ultra-low sulfur product after hydrofining are listed in Table 1.

[0068] For raw material A with...

Embodiment 2

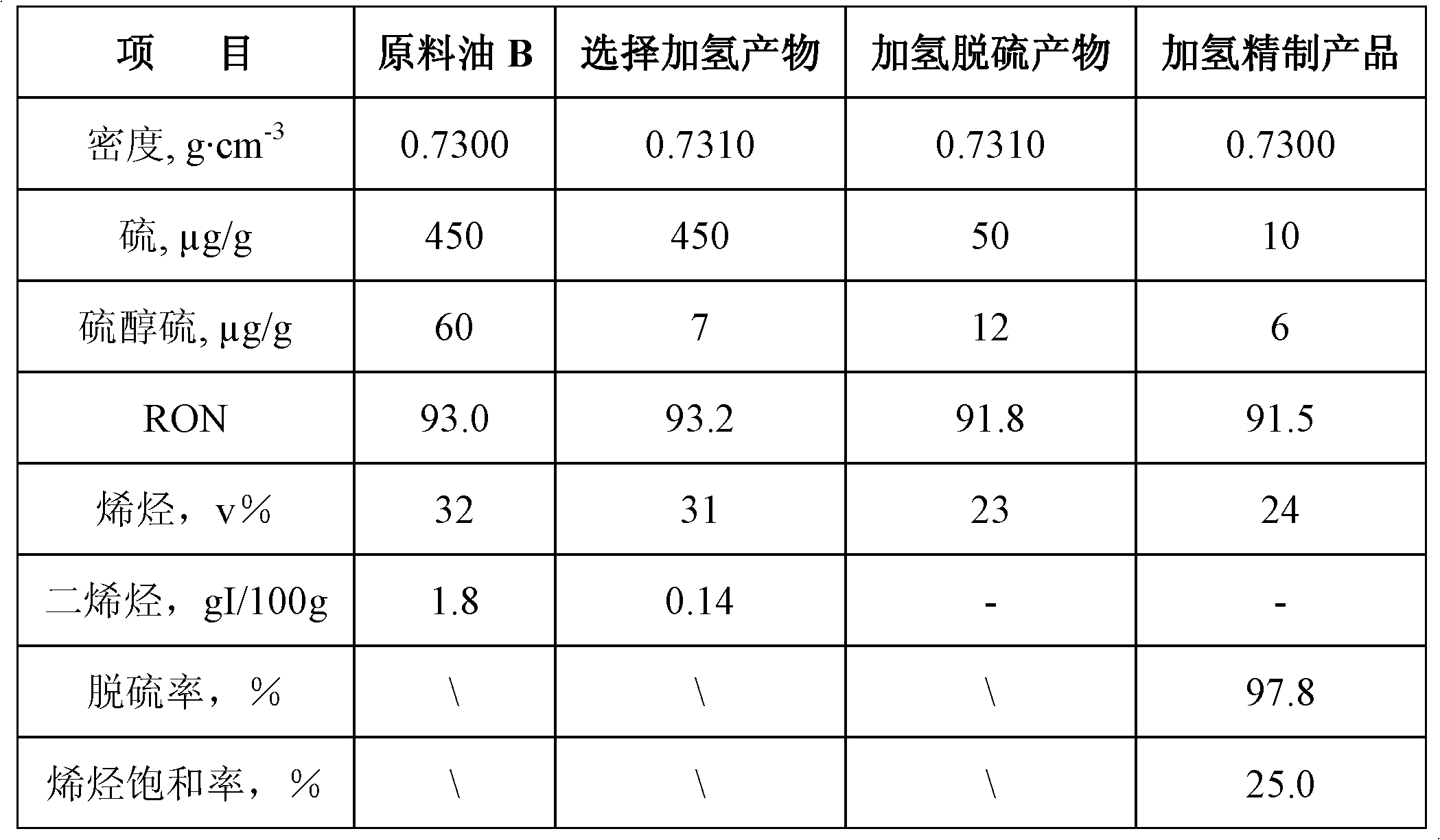

[0073] The selective hydrogenation catalyst HDDO-100, the selective hydrodesulfurization catalyst HDOS-200 and the hydrorefining catalyst HDMS-100 are installed in a 200ml small-scale hydrogenation evaluation device with three hydrogenation reactors in series, and the raw material oil B is selected. Hydrodesulfurization treatment.

[0074] The reaction conditions of the catalysts used for HDDO-100 and HDOS-200 were the same as in Example 1 except that the reaction temperature of the HDOS-200 catalyst was adjusted to 260°C.

[0075] The hydrorefining reaction conditions for HDMS-100 catalyst are as follows:

[0076] Temperature = 320°C

[0077] Pressure = 2.0MPa

[0078] Liquid space velocity = 3h -1

[0079] Hydrogen oil volume ratio = 400v / v

[0080] The properties of the intermediate product in the hydrotreating process of raw material oil B (FRCN) and the ultra-low sulfur product after hydrofining by the method of the present invention are listed in Table 2.

[0081] ...

Embodiment 3

[0087] Selective hydrogenation catalyst HDDO-100, selective hydrodesulfurization catalyst HDOS-200 and hydrorefining catalyst HDMS-100 were installed in a 200ml small-scale hydrogenation evaluation device with three hydrogenation reactors in series, and the raw material oil C was selected. Hydrodesulfurization treatment.

[0088] Except that the reaction temperatures of HDDO-100 and HDOS-200 catalysts were adjusted to 150°C and 280°C respectively, other reaction conditions were the same as in Example 2.

[0089] The properties of the intermediate product in the hydrotreating process of raw oil C and the ultra-low sulfur product after hydrofining are listed in Table 3.

[0090] The resulting gasoline product contained 10 μg / g of sulfur, of which mercaptan sulfur was 8 μg / g, and the loss of RON compared to feedstock C was 1.9 units.

[0091] Table 3 Example 3 results

[0092]

[0093]

[0094] * ΔRON = RON value of hydrogenation reaction product - RON value of raw oil C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com