Technological process of ground prefabrication and installation of inner shaft wall of freezing shaft

An installation process and a technology for freezing wells, which are applied in vertical shaft equipment, wellbore lining, earthwork drilling, etc., can solve problems such as hidden dangers in the safety and waterproof performance of single-layer well walls, high construction costs, and large well wall thickness, and reduce Downhole operation time, safe and reliable construction, and the effect of reducing the thickness of the inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

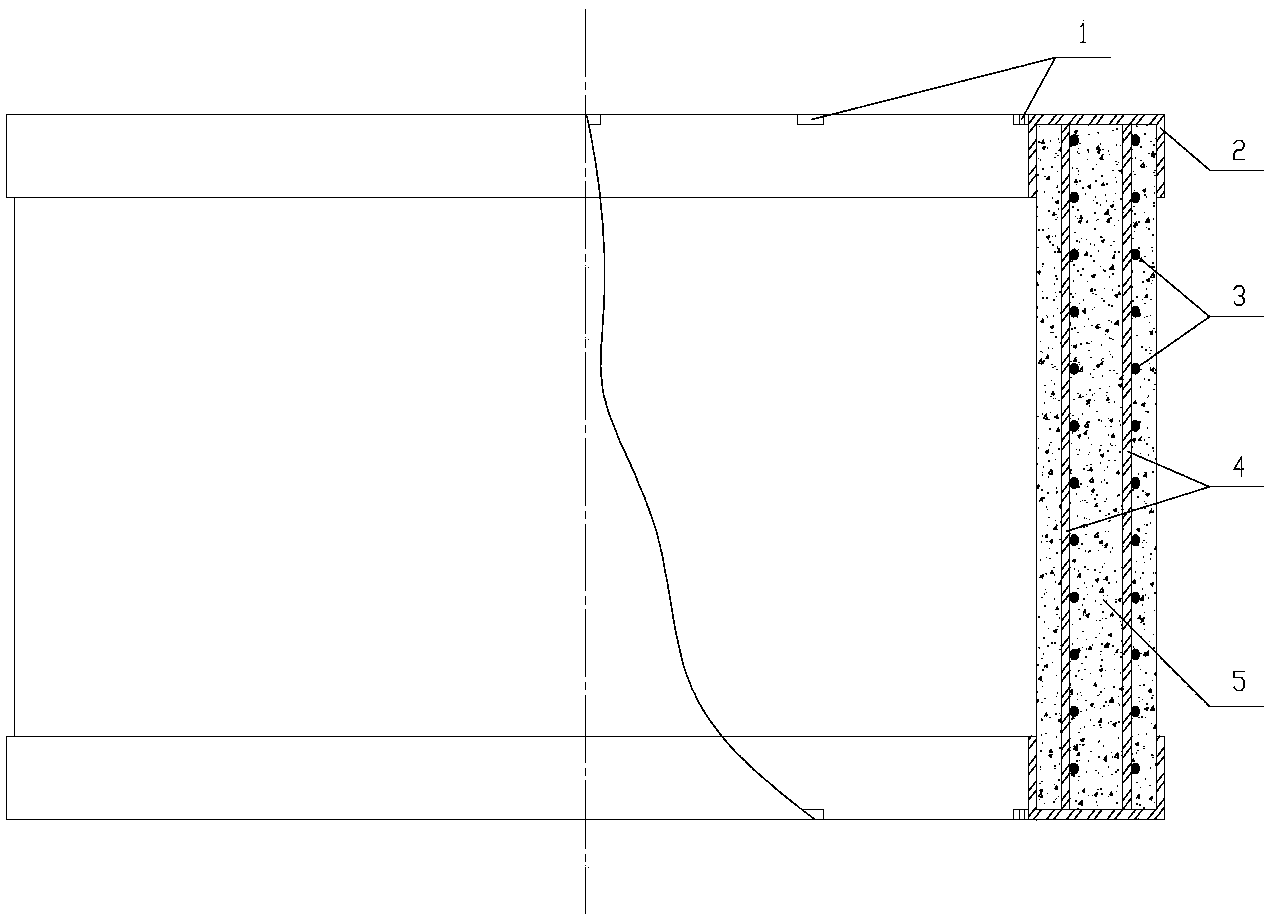

[0022] The ground prefabrication and installation process of the inner layer of the frozen shaft wall of the present invention mainly includes the following steps:

[0023] ① Shaft wall prefabrication: While the shaft is being excavated, the inner shaft wall is prefabricated on the ground. In the shaft wall prefabrication step, the shaft wall is reinforced concrete shaft wall or inner steel plate composite shaft wall, and the shaft wall is made on the ground Fabricate section by section on the basis of leveling;

[0024] ② Well wall installation: After the prefabrication of the inner well wall is completed, the annular U-shaped steel is welded and assembled with the inner steel bars of the well wall body, so that the U-shaped steel and the main body form an integrated structure;

[0025] ③Sinking shaft wall: After the outer wall of the shaft is built, inject counterweight liquid into the well, so that the prefabricated inner well wall can sink slowly and control its suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com