Thermal imager used for surface feature standardization algorithm and three dimensional (3D) laser radar temperature control standardization target

A technology of laser radar and thermal imager, which is applied in the field of calibration devices for measurement, can solve problems such as unfavorable calibration, weak anti-interference ability, and low temperature, and achieve the effects of easy disassembly and transportation, simple and compact structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

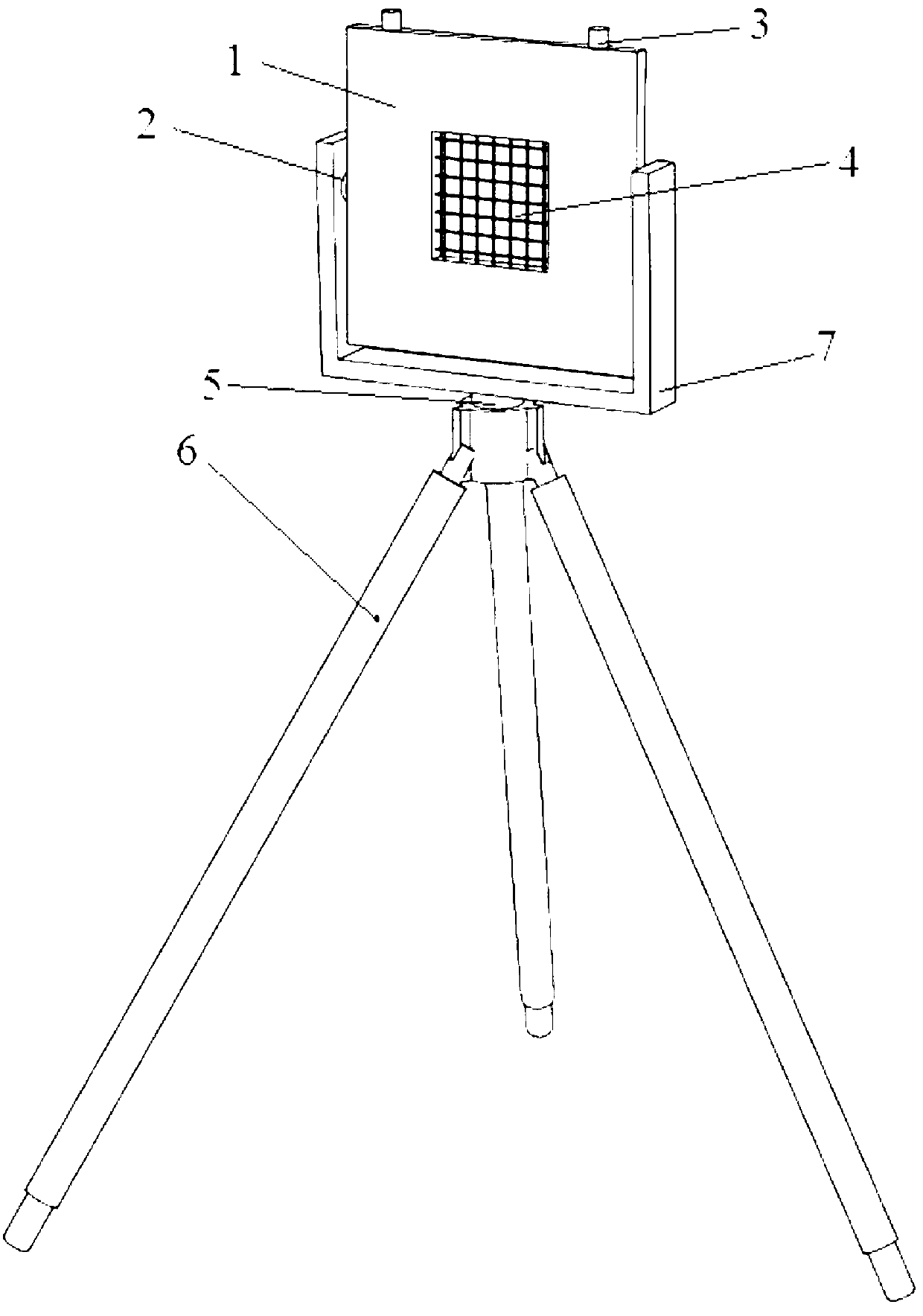

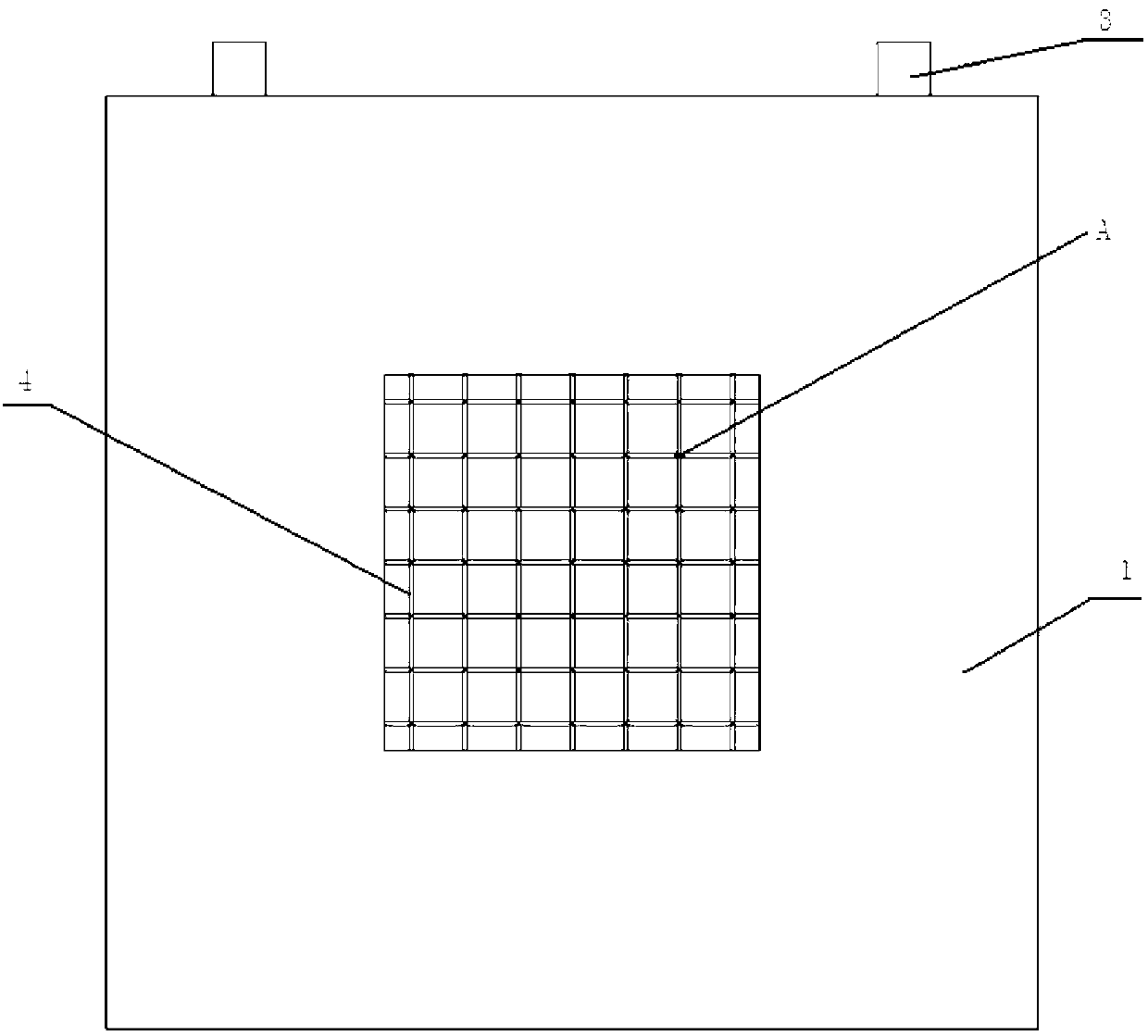

[0024] Such as figure 1 As shown, this embodiment provides a thermal imager and a 3D lidar temperature-controlled calibration target for surface feature calibration algorithms, including a heating net 4, a calibration plane 1, a heat-insulating handle 3, a support frame 7, a pitch shaft 2, Horizontal rotating shaft 5, tripod 6, temperature controller, temperature sensor and power cord.

[0025] Among them, the calibration plane 1 is made of heat-resistant hard material, and the calibration plane 1 is used to provide coplanar laser point cloud data for 3D lidar. There is a square hole in the middle of the calibration plane 1, and the heating net 4 is a grid formed by winding a complete heating wire with a high-temperature insulating layer on the outside in the square hole of the calibration plane 1. The plane where the heating net 4 is located should be en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com