Underground gas storage well wall automatic comprehensive detection system and detection method

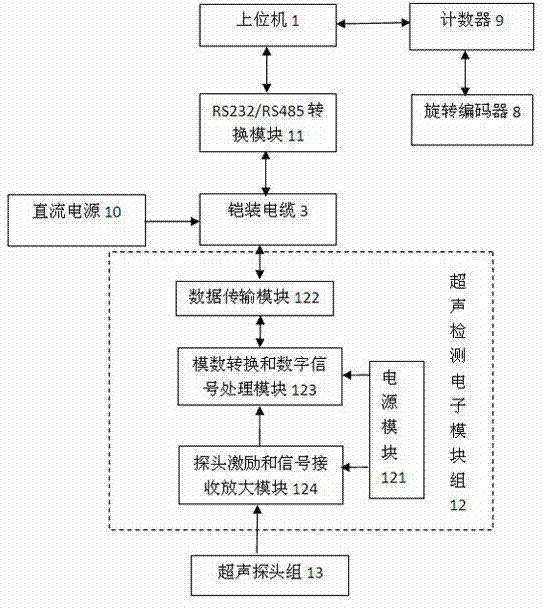

A technology for comprehensive detection and gas storage wells, which is applied to the analysis of solids using sonic/ultrasonic/infrasonic waves, which can solve the problems of incomplete detection of gas storage wells, thinning of wall thickness in local areas, and increased equipment complexity, so as to achieve accurate and reliable detection results. , The effect of reducing the failure rate and simplifying the composition of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 The ultrasonic probe group 13 includes a wall thickness corrosion detection probe group 131 and a crack detection probe group 132, the two probe groups are arranged up and down and located in the same cavity, which can be as follows Figure 5 As shown in -a, the crack detection probe group 132 is at the top, and the wall thickness corrosion detection probe group 131 is at the bottom, which can also be as follows Figure 5 As shown in -b, the crack detection probe group 132 is at the bottom, the wall thickness corrosion detection probe group 131 is at the top, and the probes of each probe group are arranged circumferentially along the circumferential direction of the cavity. Wall thickness corrosion detection and crack detection are carried out simultaneously in one downhole test.

Embodiment 2

[0036] Embodiment 2 The ultrasonic probe set 13 includes a wall thickness corrosion detection probe set 131 and a crack detection probe set 132, and the two probe sets are respectively located in two cavities. Image 6 -a is the cavity where the crack detection probe group 132 is located, Image 6 -b is the chamber where the wall thickness corrosion detection probe group 131 is located, and the probes of each probe group are arranged circumferentially along the circumference of the chamber. Wall thickness corrosion detection and crack detection are completed in two downhole tests.

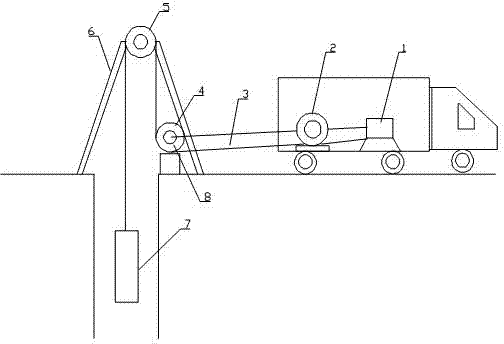

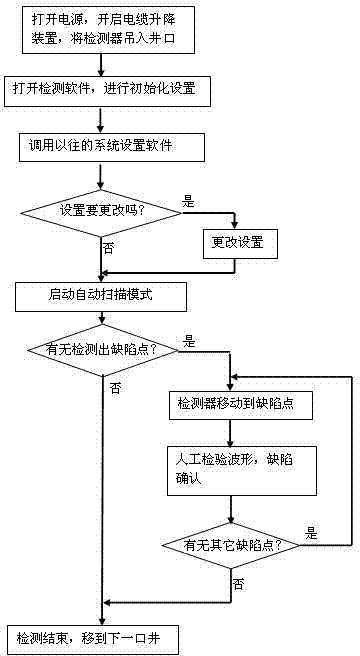

[0037] Before using the above-mentioned detection system, each device is installed. The upper computer 1, the DC power supply 10, and the cable roller 2 are located in the detection vehicle, and the operator operates the detection system on the vehicle. Pass the cable around the two rollers of the lifting device in turn, and support the roller b5 directly above the wellhead, and place the roller a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com