A Design Method of High Power and High Beam Quality Laser

A design method and high-beam technology, applied in the laser field, can solve the problems of reducing the quality of the laser beam and increasing the difficulty of laser alignment, and achieve the effect of improving the quality of the beam, increasing the power, and increasing the degree of collimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

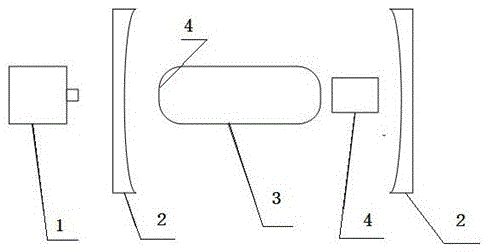

[0016] Such as figure 1 As shown, the optical resonant cavity 2 is two mirrors parallel to each other, with a heat sink outside, and the optical resonant cavity 2 has a Nd:YAG medium 3 and an acousto-optic Q-switching switch 5 . The shape of the Nd:YAG medium 3 is a convex flat-top shape, and the temperature of the Nd:YAG medium is cooled by a fan.

[0017] The end pump 1 is on the end face of the optical resonant cavity 2, and the end pump 1 irradiates the receiving surface 4 of the Nd:YAG medium, and the symmetry plane between the receiving surface 4 and the receiving surface of the Nd:YAG medium is a plane with an inscribed circle radius of 1 cm. In this case, the transmittance of the medium to the light source is 20%.

[0018] Under the action of the convex flat-top medium, the pump light source will form a convergence, and the number of inverted particles in the medium in the resonant cavity will be significantly increased. Under the action of the acousto-optic Q-switchi...

Embodiment 2

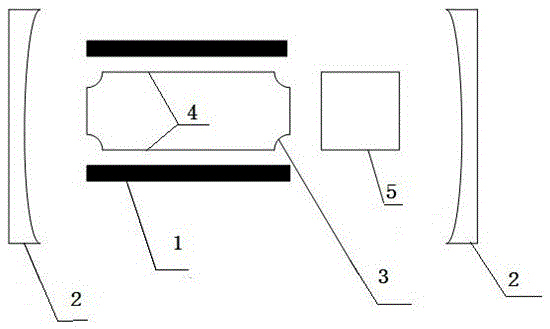

[0020] Such as figure 2 As shown, there is a concave flat-top Nd:YAG medium 4 and an acousto-optic Q-switching switch 5 between the two parallel mirrors of the optical resonant cavity 2. There is a heat sink outside the optical resonant cavity 2, and the fan cools the concave flat-top medium .

[0021] The pumping light source 1 is side pumping, and the side pumping is on the side of the optical resonant cavity 2, the receiving surface 4 of the Nd:YAG medium is a plane, and its inscribed circle radius is 1cm, and the transparent surface of the concave flat-top Nd:YAG medium 20% failure rate

[0022] The side pump increases the number of reversed particles in the medium in the resonant cavity. Under the action of the acousto-optic Q-switched switch, the number of reversed particles is continuously accumulated. When the Q switch is turned on, the oscillating light is stimulated to emit Amplification and power increase form a pulsed laser. Due to the unique shape of the medium...

Embodiment 3

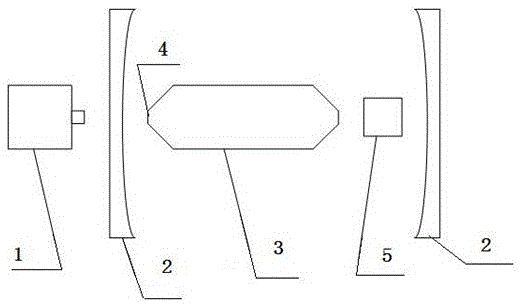

[0024] Such as image 3 As shown, the structure of this embodiment is basically the same as that of Embodiment 1. The difference is that the shape of the Nd:YAG medium 3 is a conical flat-top shape, and the conical flat-top Nd:YAG medium is in effect the same as the convex flat top. The shape medium is the same, the radius of the inscribed circle of their receiving surface is 1cm, and the same effect can be obtained.

[0025] The shape of the Nd:YAG medium 3 can also be a flat top shape of a spherical surface, a flat top shape of an ellipsoidal surface, a flat top shape of a parabolic surface, and a flat top shape of a hyperbolic surface. Their functions and effects are also the same, and will not be detailed here. introduce.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com