Electromagnetic shielding method and products thereof

A technology of electromagnetic shielding and products, applied in the fields of magnetic/electric field shielding, chemical instruments and methods, electrical components, etc., can solve the problems of poor shielding performance and zero electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Sand blasting treatment: the sand used is ceramic sand of model 80#, and the sand blasting pressure is 1.2MPa.

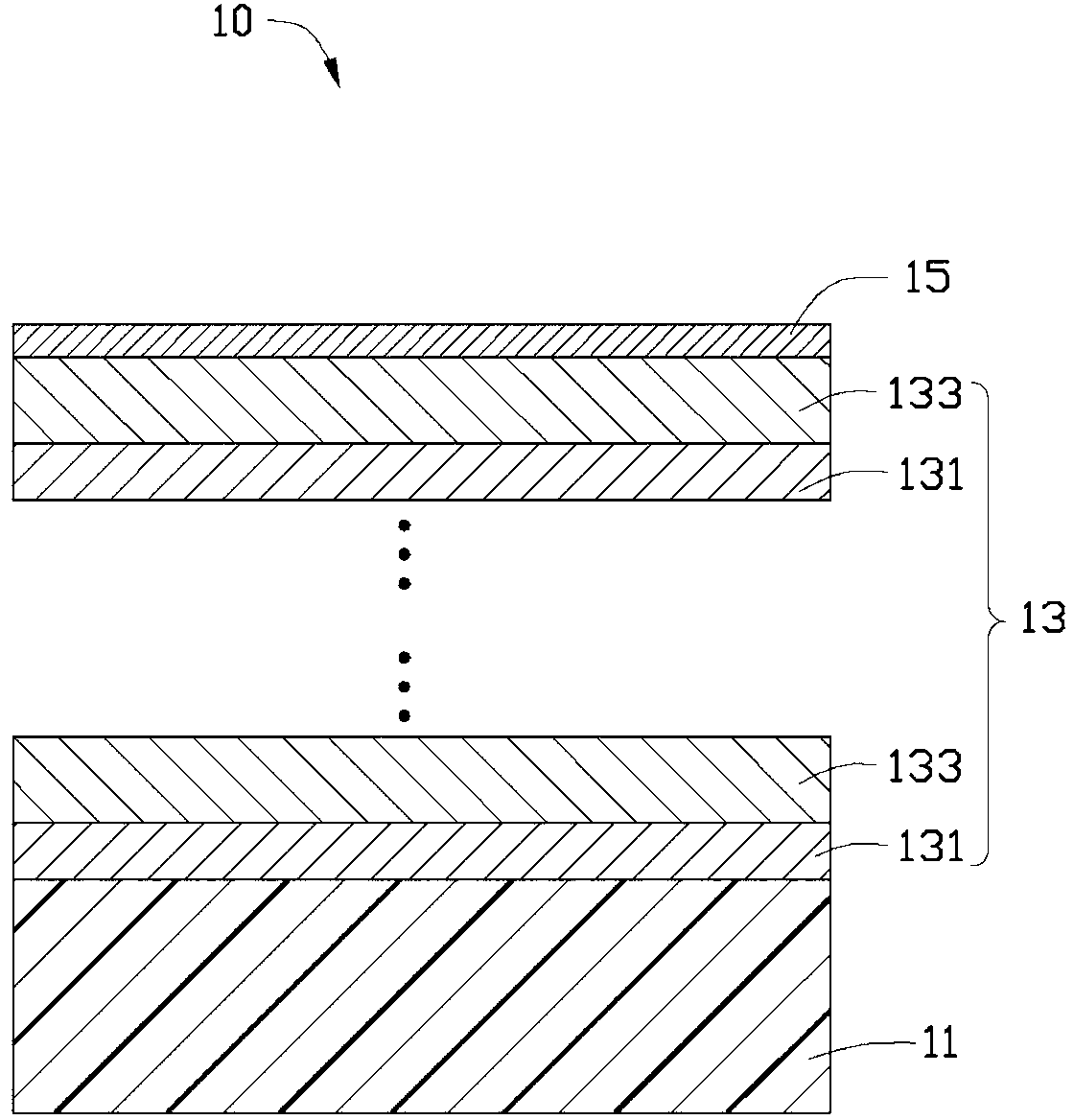

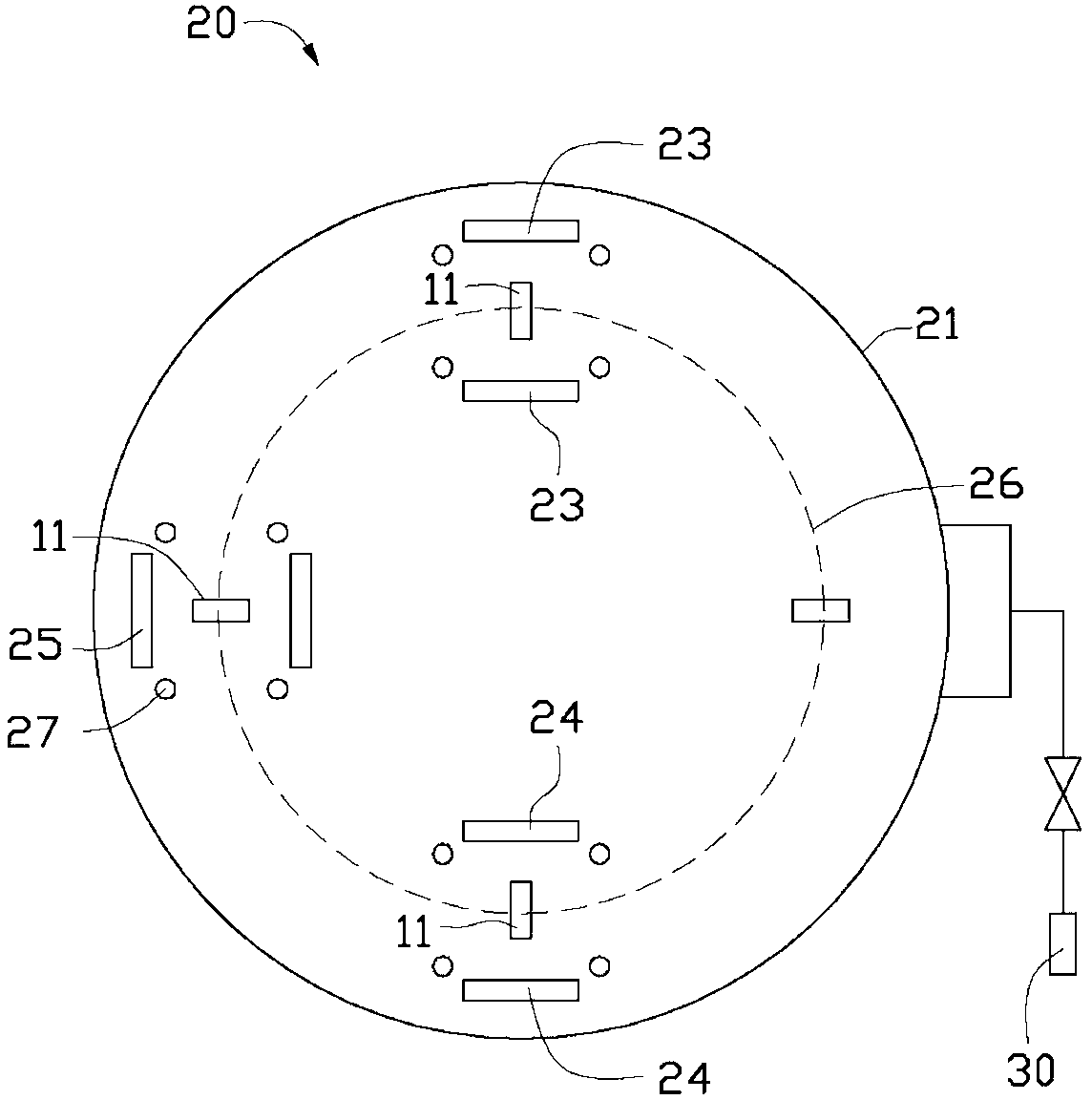

[0031] Sputtering metal composite layer 13: vacuumize coating chamber 21 to 4.0×10 -3 Pa, then pass into the argon gas of flow rate about 180sccm in the coating chamber 21, the power that the first target material 23 is set is 10kW, the power that the second target material 24 is set is 5kW; Described film coating temperature is room temperature, and film coating time is 6min. Wherein, the first target material 23 is a copper layer, and the second target material 24 is a nickel layer. The thickness of the metal composite layer 13 is 0.2 μm.

[0032] Sputtering protective layer 15: set its power to 8kw; argon gas flow rate to 180 sccm; the temperature of the coating chamber 21 is room temperature, and the coating time can be 5 minutes. Wherein, the third target material 25 is a stainless steel layer. The thickness of the protection layer 15 is 0.1 μm.

Embodiment 2

[0034] Sand blasting treatment: the sand used is ceramic sand of model 80#, and the sand blasting pressure is 1MPa.

[0035] Sputtering metal composite layer 13: vacuumize coating chamber 21 to 6.0×10 -3 Pa, then pass into the argon gas that flow rate is about 200sccm in coating chamber 21, the power that the first target material 23 is set is 12kW, the power that the second target material 24 is set is 6kW; Described coating temperature is room temperature, coating time is 10min. Wherein, the first target material 23 is a silver layer, and the second target material 24 is a nickel layer. The thickness of the metal composite layer 13 is 0.4 μm.

[0036] Sputtering protective layer 15: set its power to 10kw; argon gas flow rate to 200 sccm; the temperature of the coating chamber 21 is room temperature, and the coating time can be 10 minutes. Wherein, the third target material 25 is a stainless steel layer. The thickness of the protection layer 15 is 0.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com