Smoked processed cheese and preparation method thereof

A processed cheese and smoking technology, which is applied in the field of processed cheese, can solve the problems of difficulty in obtaining cheese slices, inability to smoke in place, easy breakage of cheese slices, etc., to achieve uniform appearance and state, moderate elasticity and hardness, and fusion of flavors high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

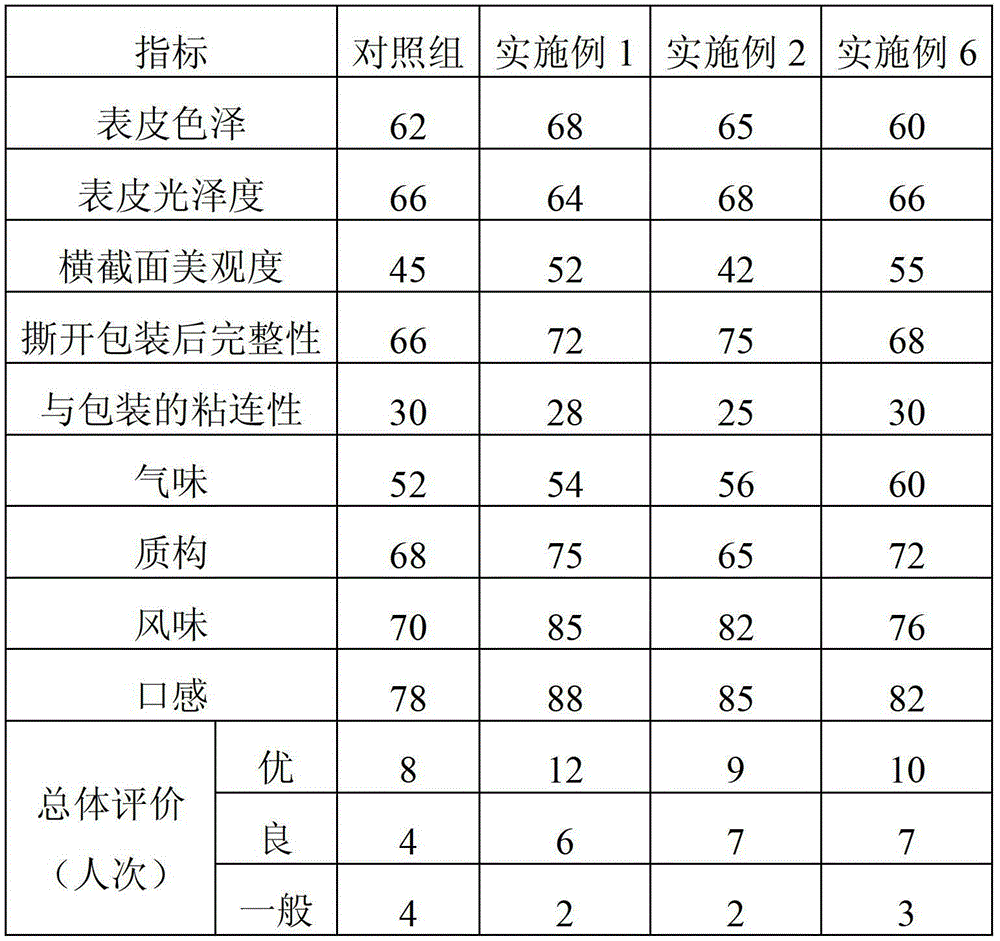

Examples

Embodiment 1

[0043] The raw material formula of smoked processed cheese is shown in Table 1.

[0044] The raw material formula of the smoked processed cheese of table 1 embodiment 1

[0045] raw material

Contentwt%

3 months mature cheddar cheese

42

28

1.56

Sodium citrate

1.4

4

smoke liquid

0.04

water

23

total

100

[0046] A method for preparing smoked processed cheese, comprising the steps of:

[0047] (1) Finely cut the cheddar cheese and mozzarella cheese that have matured for 3 months, and then stir with the raw materials except the smoked liquid at 70°C for 8 minutes, then add the smoked liquid, continue to stir for 1 minute, and use Ultra-high temperature instantaneous sterilization: Sterilize at 138°C for 5s, stir and emulsify at 700rpm at 88°C for 8min to obtain a mixture;

[0048] (2) Use the method of vacuuming to remo...

Embodiment 2

[0052] The raw material formula of smoked processed cheese is shown in Table 2.

[0053] The raw material formula of the smoked processed cheese of table 2 embodiment 2

[0054] raw material

Contentwt%

6 months old cheddar cheese

42

18

butter

3

1.5

Sodium citrate

1.5

smoke liquid

0.03

7

water

26.78

cheese essence

0.1

0.09

total

100

[0055] A method for preparing smoked processed cheese, comprising the steps of:

[0056] (1) Finely cut the cheddar cheese and mozzarella cheese that have matured for 6 months, and then stir with the raw materials except the smoked liquid at 80°C for 5 minutes, then add the smoked liquid, continue to stir for 1 minute, and use Ultra-high temperature instantaneous sterilization: Sterilize at 139°C for 4s, stir and emulsify at 85°C at a speed o...

Embodiment 3

[0061] The raw material formula of smoked processed cheese is shown in Table 3.

[0062] The raw material formula of the smoked processed cheese of table 3 embodiment 3

[0063] raw material

Contentwt%

3 months mature cheddar cheese

45

anhydrous butter

6.4

1

potassium citrate

1

rennet casein

11

smoke liquid

0.02

salt

0.5

water

35

0.08

total

100

[0064] A method for preparing smoked processed cheese, comprising the steps of:

[0065] (1) Finely cut the cheddar cheese that has matured for 3 months, then stir it with raw materials other than the smoked liquid at 68°C for 10 minutes, then add the smoked liquid, continue stirring for 1 minute, and use ultra-high temperature instantaneous sterilization : Sterilize at 140°C for 2s, stir and emulsify at 87°C at a speed of 1000rpm for 5min to obtain a mixture;

[0066] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com