Long-term storage method of grain dreg type feed

A technology of slag and feed, which is applied in the field of long-term storage of slag feed, can solve the problems of seasonal supply imbalance of slag feed, increase fuel cost, waste feed resources, etc., achieve significant fly-proof effect and improve utilization efficiency , the effect of reducing nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Take 10 tons of brewer's grains (85.3% water content) as an example for storage by adding feed-grade ammonium chloride:

[0015] 1) Calculate the required amount of ammonium chloride: calculate by 0.3% of the fresh weight of brewer's grains, and the total amount of ammonium chloride required is 30 kilograms;

[0016] 2) prepare ammonium chloride saturated solution: dissolve 30 kilograms of ammonium chloride in 75 kilograms of water;

[0017] 3) In the process of filling the brewer's grains, spray the ammonium chloride saturated solution into the mixture and store it;

[0018] 4) Judging from the quality and property changes of brewer's grains during storage, the storage time of brewer's grains has reached more than 1 year, and has a significant anti-fly effect during the storage period.

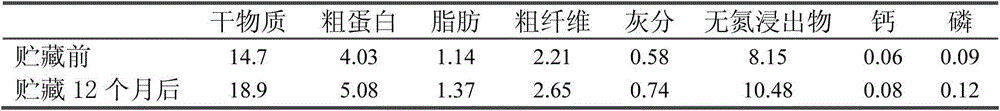

[0019] Table 1 Changes of nutritional components of brewer's grains before and after storage with 0.4% ammonium chloride (%)

[0020]

[0021] Note: For the determination method, ...

Embodiment 2

[0023] Take 25 tons of cassava residues (moisture content 81.8%) to store by adding feed grade ammonium chloride as an example:

[0024] 1) Calculate the ammonium chloride requirement: calculate by 0.4% of the fresh weight of cassava dregs, and the required ammonium chloride total amount is 100 kilograms;

[0025] 2) Prepare saturated solution of ammonium chloride: dissolve 100 kilograms of ammonium chloride in 250 kilograms of water;

[0026] 3) In the process of filling cassava residues, spray saturated ammonium chloride solution into the mixture and store after mixing;

[0027] 4) Judging from the quality and property changes of cassava residues during storage, the storage time of cassava residues has reached more than 1 year, and has a significant anti-fly effect during the storage period.

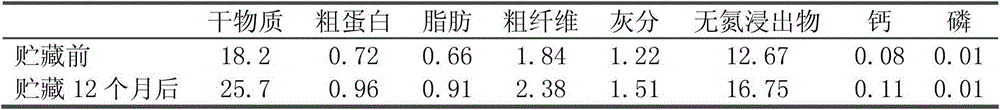

[0028] Table 2 Changes of nutrients in cassava residue before and after storage with 0.4% ammonium chloride (%)

[0029]

[0030] Note: For the determination method, refer to "Fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com