Grinding amount on-line monitoring device at ring-polishing stage and grinding amount on-line monitoring method

A monitoring device and a grinding amount technology are applied in the field of real-time monitoring of the grinding amount and the field of devices for realizing online monitoring of the grinding amount, which can solve problems such as reducing the processing efficiency of workpieces, reduce detection costs, simple adjustment steps, and reduce dependence. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

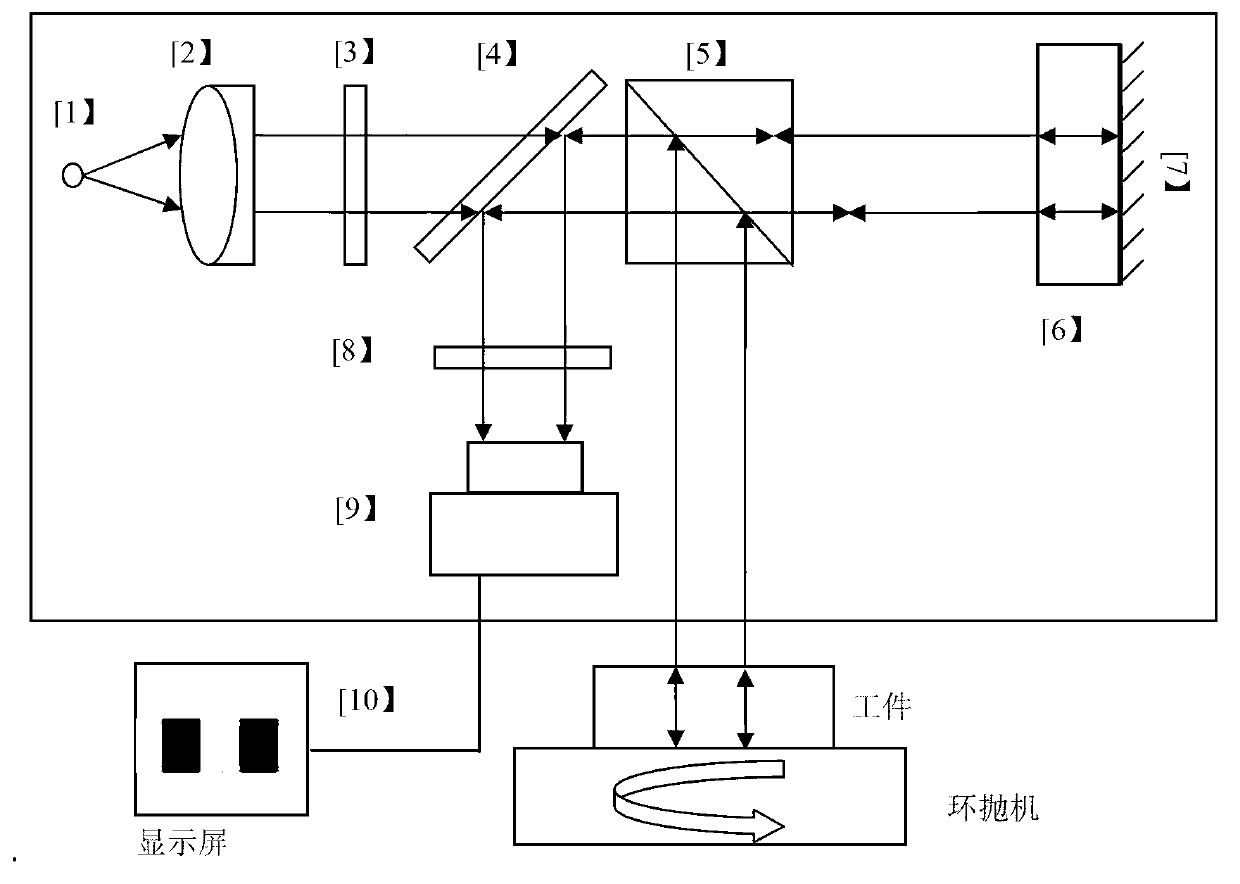

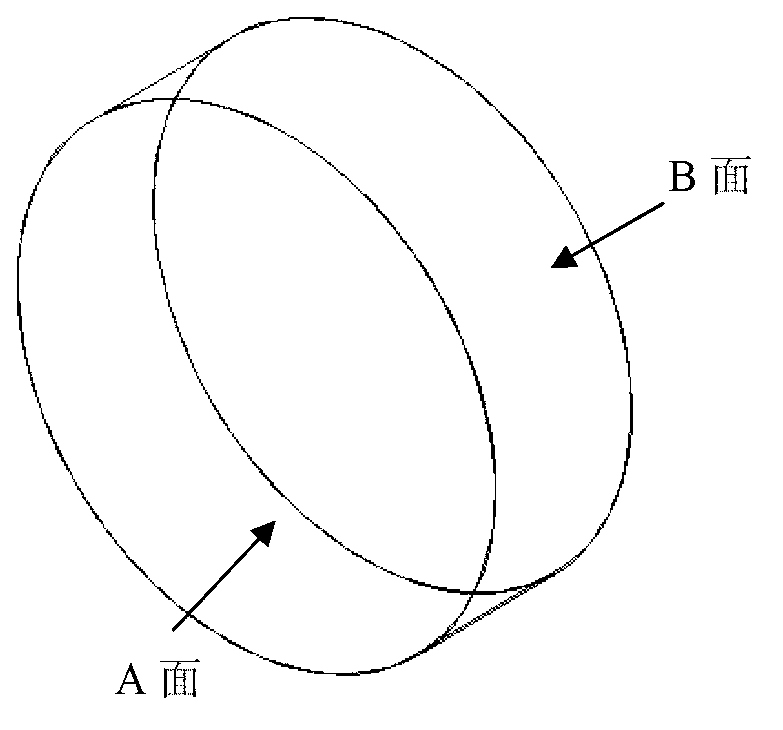

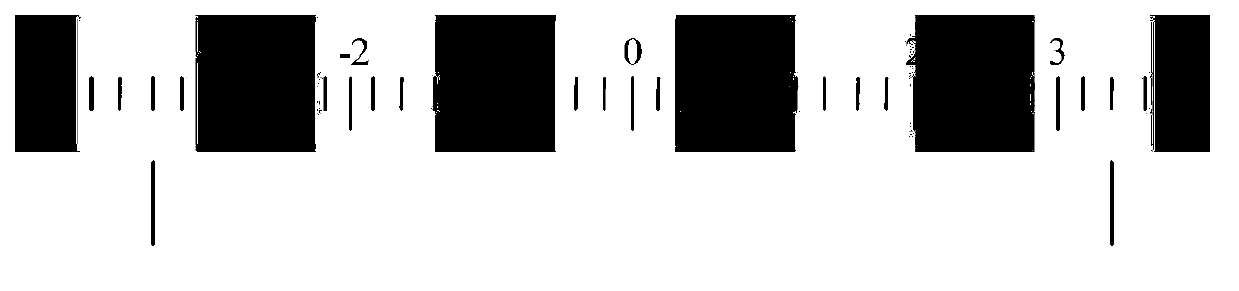

[0026] The amount of glass grinding reflects the variation of the optical path difference in the grinding amount monitoring device, and the variation of the optical path difference is reflected as the offset of the stripes. By monitoring the offset of the stripes, the purpose of online monitoring of the grinding amount can be achieved. To realize this invention, the following contents need to be included:

[0027] 1. Provided is an on-line monitoring device for white light interference workpiece grinding amount (hereinafter referred to as the grinding amount monitoring device) that can be used in a ring polishing machine. The device can adjust the contrast of white light interference fringes, and can also eliminate the influence of dispersion on white light interference.

[0028] 2. A method for online monitoring of grinding amount based on a grinding amount monitoring device is provided, which includes two steps:

[0029] a. The grinding amount monitoring device is calibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com