Hydraulically-driven vehicle chassis and construction machinery

A hydraulic transmission and vehicle technology, which is applied to vehicle components, control devices, transportation and packaging, etc., can solve problems such as the inability to guarantee the straight running of the vehicle, the narrow speed range of the vehicle, and the out-of-synchronization of the motor, which is conducive to changing the design and realizing Optimal matching, great starting acceleration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

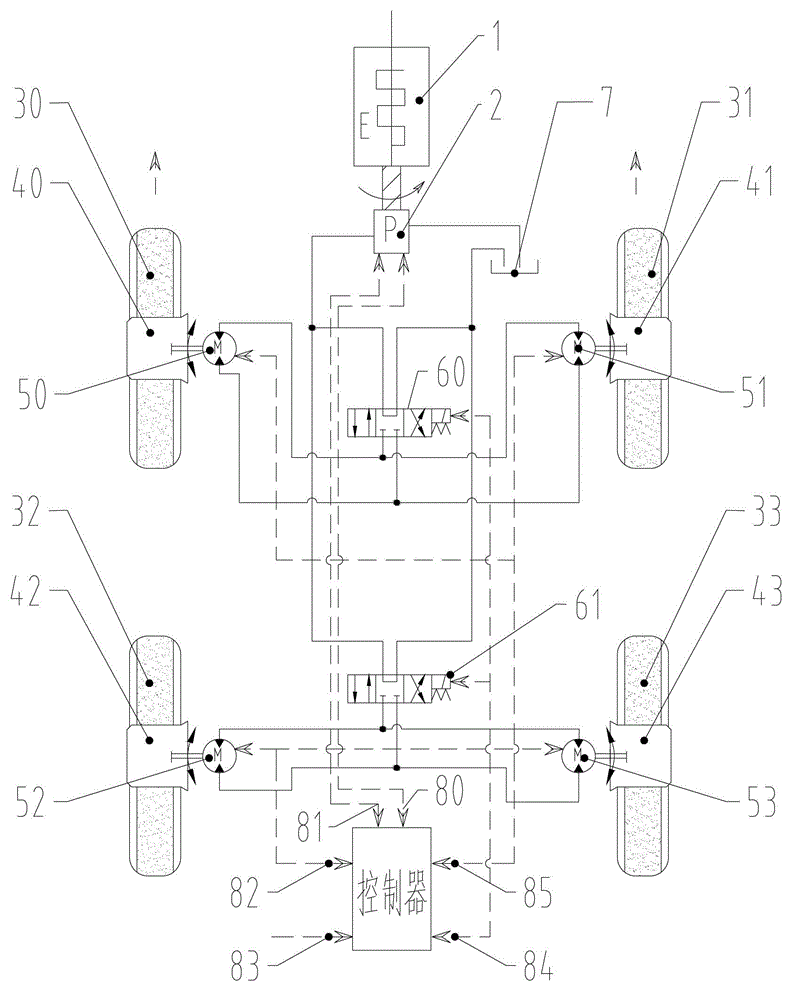

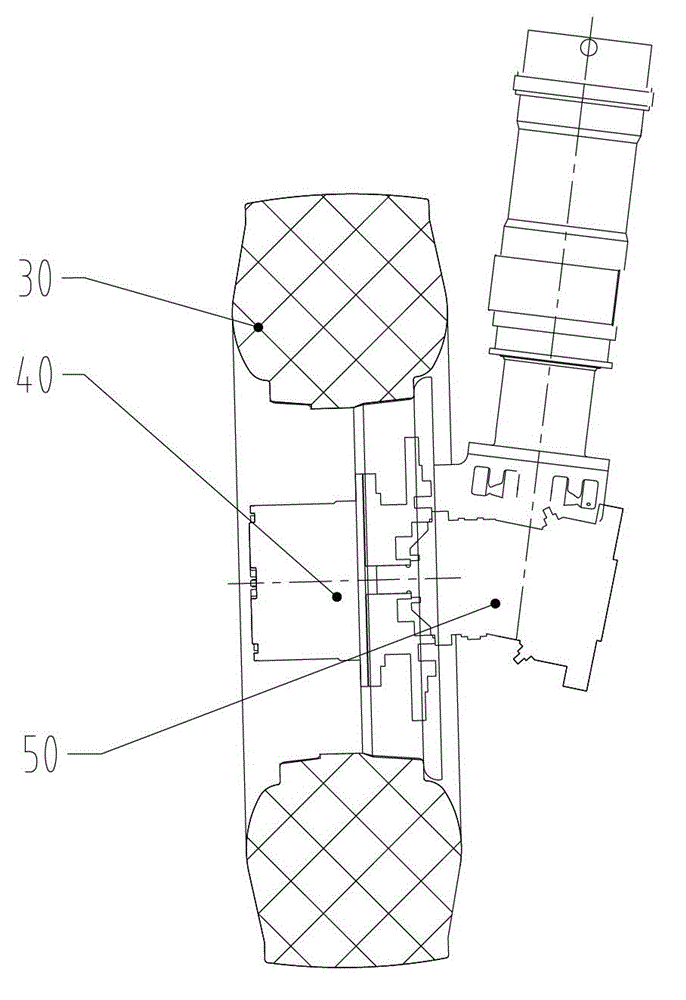

[0027] Such as figure 1 As shown, a hydraulically driven vehicle chassis includes: an engine 1, a variable displacement pump 2, four wheels, four variable displacement motors, two reversing valves, and a fuel tank 7. The engine 1 drives the variable displacement pump 2 to pump oil, and the variable displacement pump 2 Hydraulic oil is supplied to each variable motor through a reversing valve, and the oil return circuit of each variable motor communicates with the oil tank 7 . Four wheels comprise the left front wheel 30 and the right front wheel 31 positioned at the front axle, the left rear wheel 32 and the right rear wheel 33 positioned at the rear axle; The rotating right front variable moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com