Hydraulic power-assisted electric cylinder and control method thereof

A technology of hydraulic power assist and control method, which is applied in the direction of fluid pressure actuating device, etc., to achieve the effects of small heat generation, large force and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

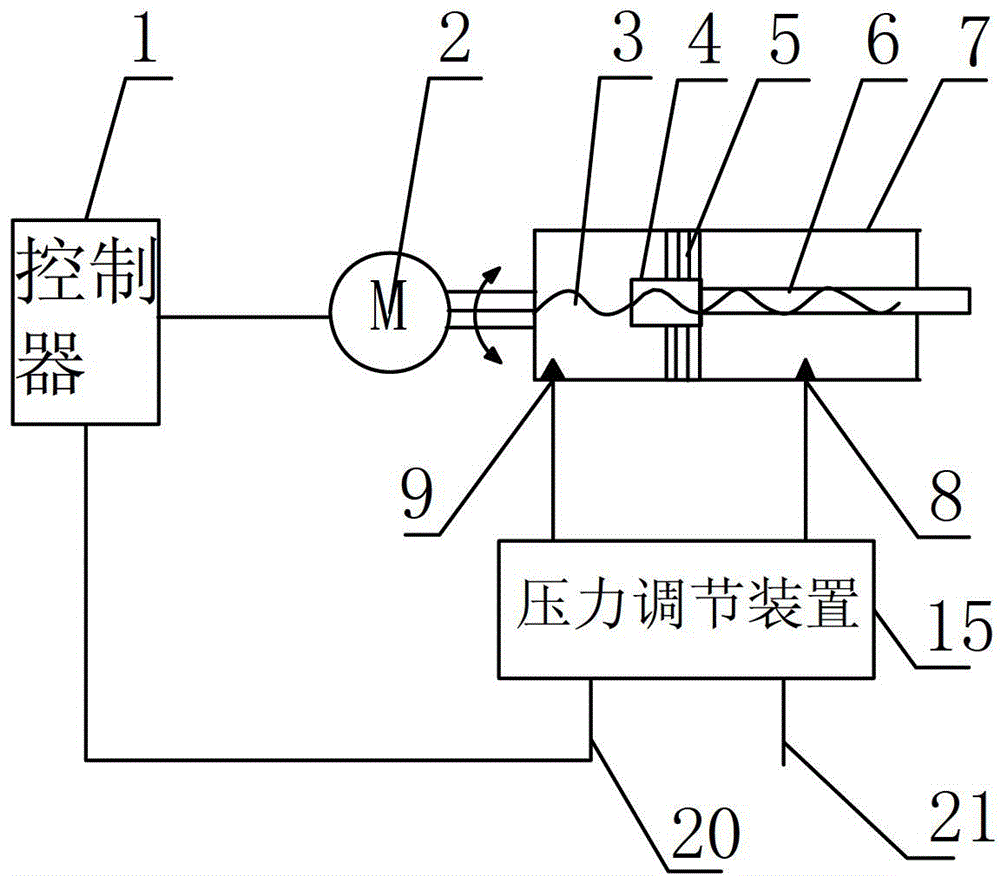

Method used

Image

Examples

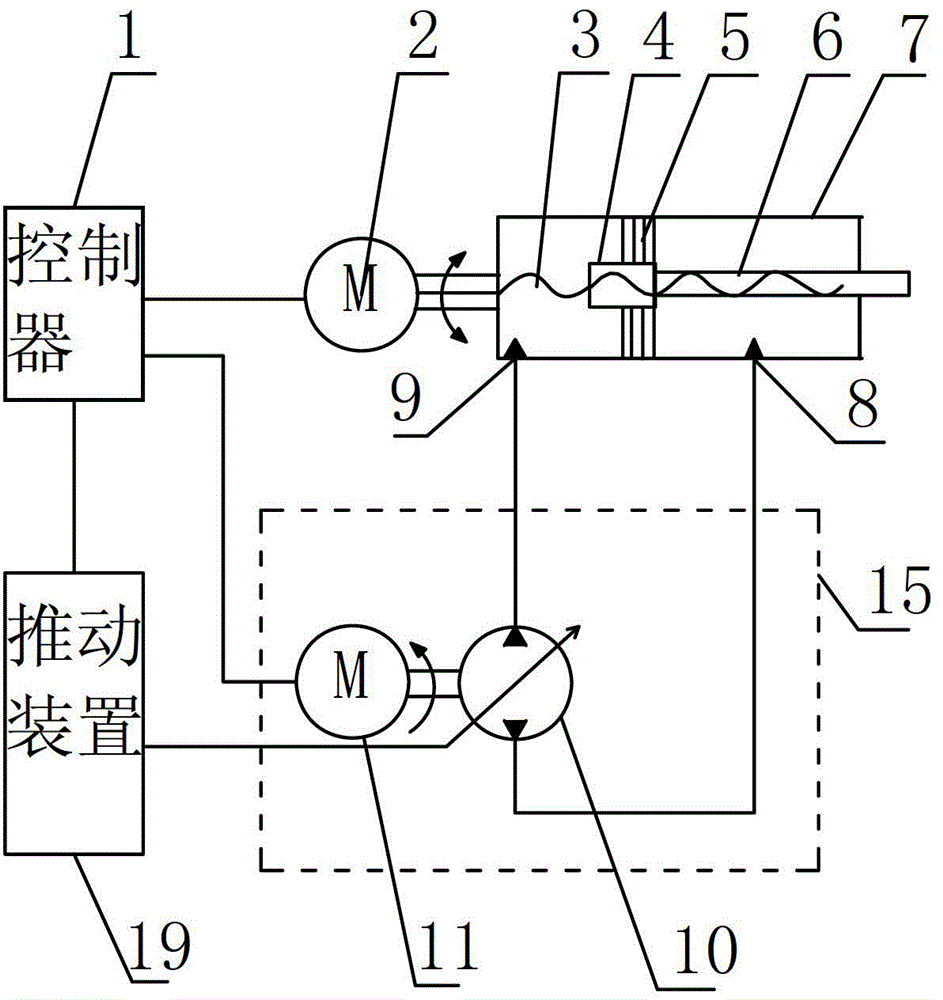

Embodiment 2

[0031] Embodiment 2, the pressure regulating device 15 includes a three-position four-way reversing valve 16, a hydraulic pump 17 driven by a hydraulic pump motor 11, and the two output ends of the hydraulic pump 17 are respectively connected to the three-position four-way The P and O ends of the reversing valve are communicated, and the A and B ends of the three-position four-way reversing valve are respectively communicated with the piston rod side oil hole 8 and the piston side oil hole 9 . like Figure 4 , the pressure value is adjusted by the controller 1 controlling the frequency converter 12 to drive the hydraulic pump motor 11 in the pressure regulating device 15 to adjust the hydraulic pressure entering the cylinder in a frequency conversion manner; the hydraulic pump motor 11 Drive the hydraulic pump 17, and connect the two output ends of the hydraulic pump 17 to the P and O ends of a three-position four-way reversing valve 16 located in the pressure regulator 15, an...

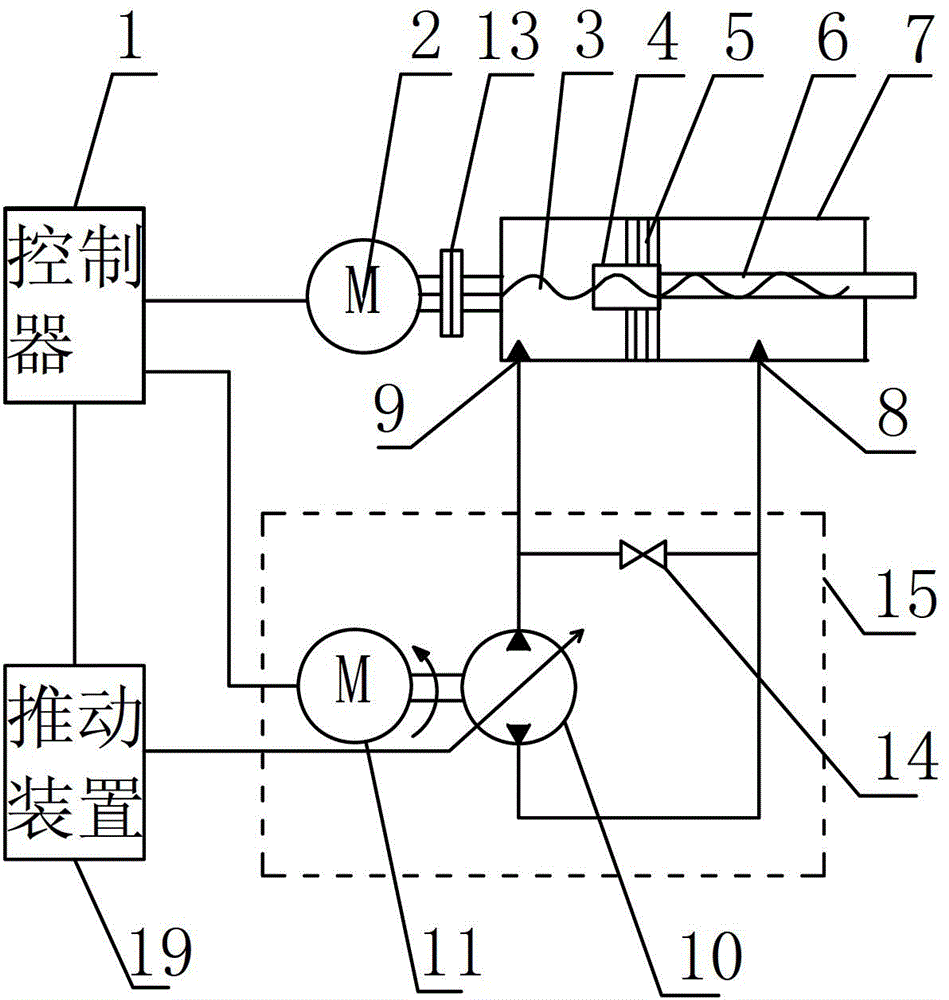

Embodiment 3

[0036] Embodiment three, such as Figure 5 , the pressure regulating device 15 includes a three-position four-way reversing valve 16 and a pressure reducing valve 18, the P port of the three-position four-way reversing valve communicates with the A port of the pressure reducing valve 18, and the three-position Ports A and B of the four-way reversing valve communicate with the piston rod side oil hole 8 and the piston side oil hole 9 respectively. like Figure 5 , the pressure value is adjusted by controlling the pressure reducing valve 18 in the pressure regulating device 15 by the controller to adjust the hydraulic pressure entering the cylinder body; the A port of the pressure reducing valve 18 is connected with the pressure regulating device 15 Connect the P port of a three-position four-way reversing valve 16 inside, connect the O port of the three-position four-way reversing valve and the Y port of the pressure reducing valve 18 into the return flow, and connect the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com