Magnetic damping belt pulley

A pulley and magnetic technology, applied in belts/chains/gears, components with teeth, hoisting devices, etc., can solve the problems of poor stability, low resistance of vibration-absorbing pulleys, and low life expectancy, and achieve excellent performance and reduce crankshaft. Torsional vibration, effect of reducing crankshaft stress levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

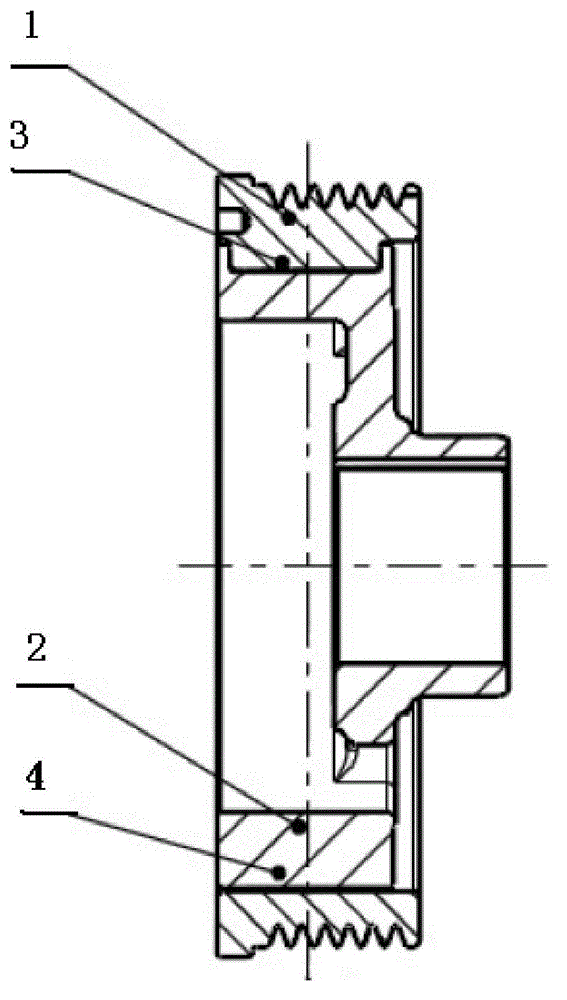

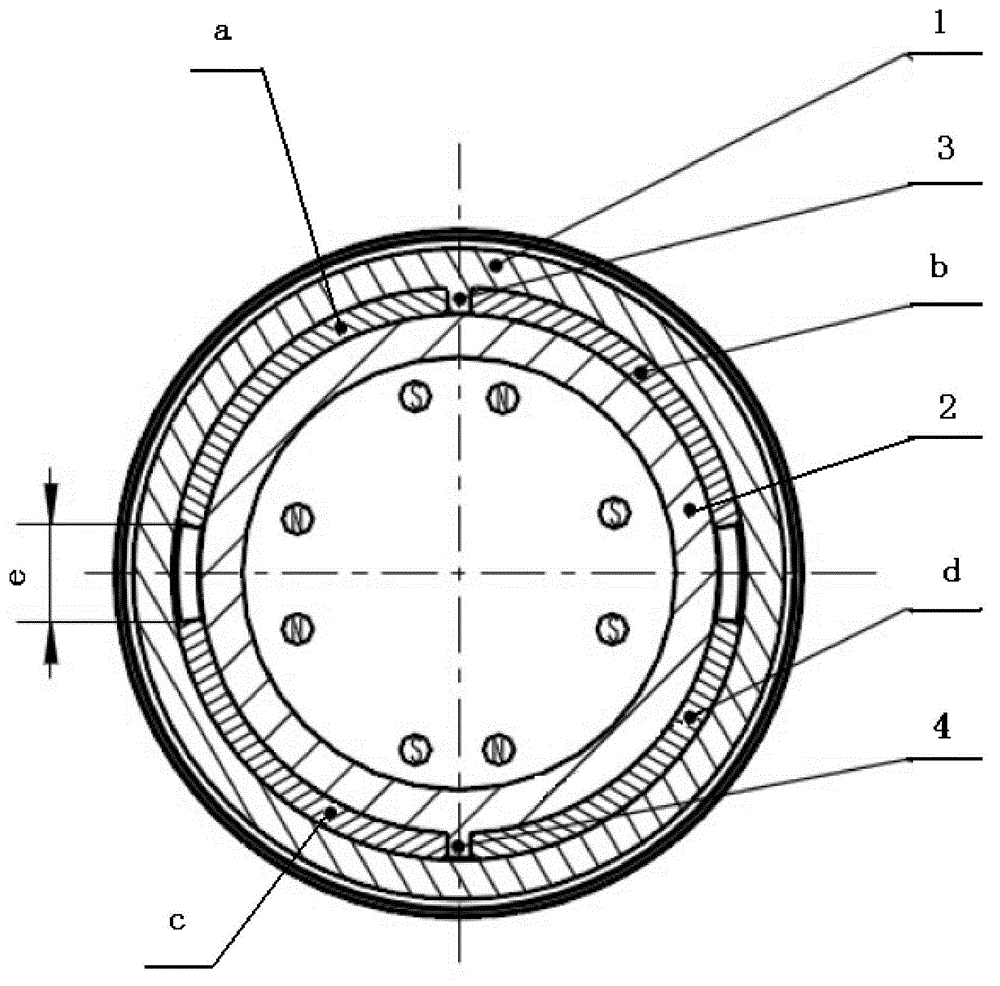

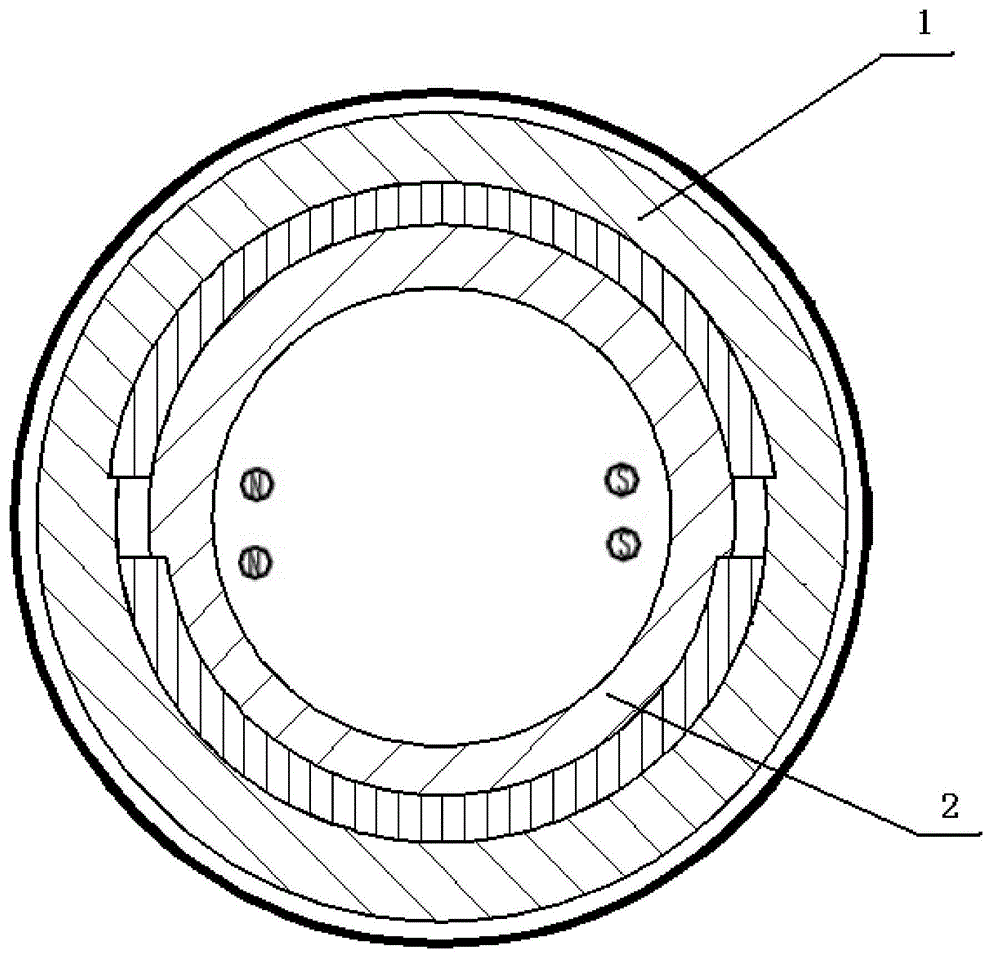

[0024] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention provides a magnetic damping pulley, including a pulley 1 and a hub 2 set inside the pulley 1, the pulley 1 and the hub 2 can rotate relatively, and a first magnet is arranged between the pulley 1 and the hub 2 and a second magnet;

[0025] When the wheel hub 2 rotates, first the first magnet is pushed to rotate, and then the first magnet pushes the second magnet to rotate through repulsive force, and the second magnet then pushes the belt pulley 1 to rotate.

[0026] Wherein, between the first magnet and the second magnet and the pulley 1 and the hub 2 can be such as figure 2 The connection relationship shown in , can also be as image 3 The connection relationship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com