Cold circulation refrigeration system

A refrigeration device and refrigeration technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of not being equal to 1, not giving a clear answer, and not being able to explain the refrigeration cycle concisely, clearly and intuitively.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

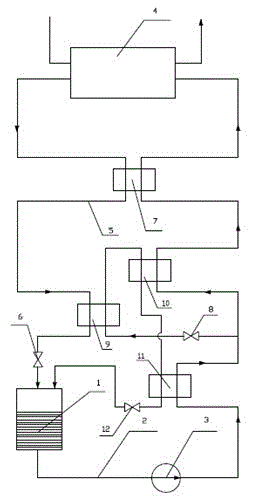

[0091] Such as figure 1 As shown, a cold cycle refrigeration device, the refrigerant adopts liquid nitrogen, the specific examples are as follows:

[0092]The liquid refrigerant 2 coming out of the refrigerant storage tank 1 is divided after passing through the liquid circulation pump 3 and the sub-refrigerator 11, and the refrigerant flowing out of it passes through the throttling valve 8, the sub-cooler 9 and the sub-refrigerator 10 , recooler 11, throttling valve 12 returns to the refrigerant storage tank 1, and another way of refrigerant passes through recooler 10, recooler 7, cooling unit 4, recooler 7, recooler 9, throttle valve 6 to return to the refrigerant storage tank 1, thereby forming a refrigeration cycle of the refrigerant.

[0093] The recooler 7, recooler 9, recooler 10, and recooler 11 adopt traditional plate-fin heat exchangers or micro-channel heat exchangers; the refrigerant storage tank 1 adopts an insulated vacuum container , Pearlescent sand is used as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com