Real-time data acquisition method and acquisition system for three-dimensional detection of aggregates on the production site

A technology of real-time data collection and three-dimensional detection, which is applied in the direction of measuring devices, particle size analysis, scientific instruments, etc., can solve the problems of difficult separation of particles, low accuracy of data acquisition, and difficult handling, so as to ensure measurement accuracy, improve test efficiency, Effect of increasing roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

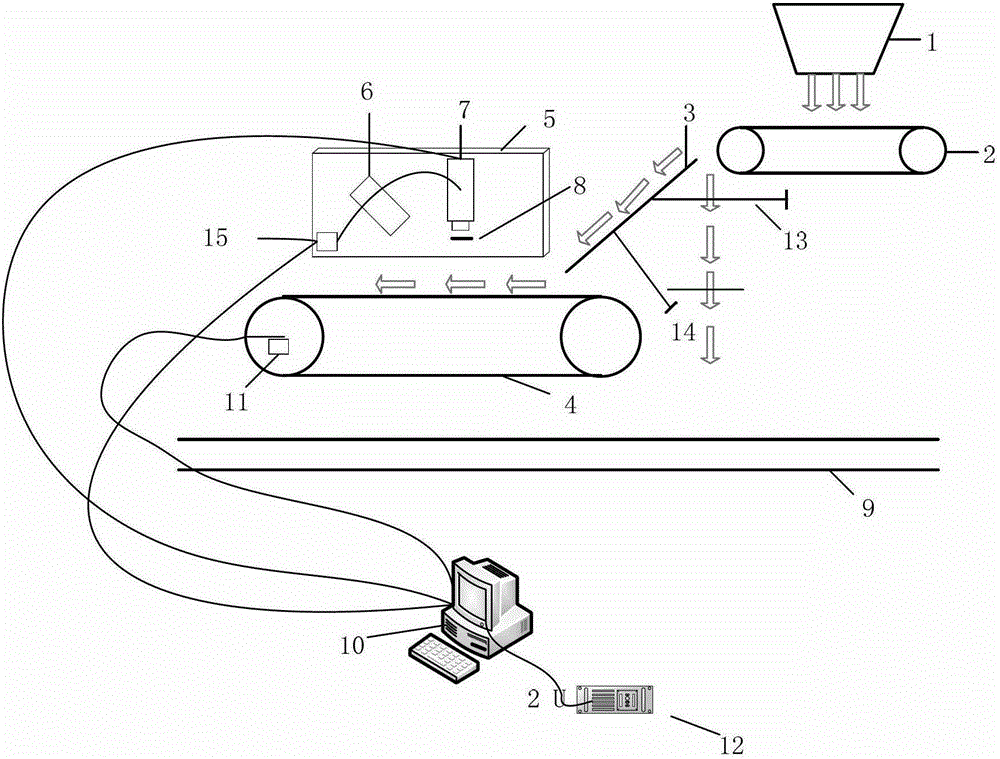

[0049] Such as figure 1 As shown, the real-time data acquisition method of the production site aggregate three-dimensional detection of the present invention comprises the following steps:

[0050] Step 1, set up a collection conveying device, which includes a feed bin (1), a primary transmission belt (2), a distribution plate (3) and a total transmission belt (9), wherein the feed bin (1 ) is located above the material input end of the primary transmission belt (2), and the total transmission belt (9) is located below the primary transmission belt (2); the distribution plate (3) is lower than the primary transmission belt (2) and the distribution plate (3) ) The upper end is close to the material output end of the primary conveyor belt (2), and the horizontal distance between the two is 5~15cm (preferably 8cm); the distribution plate (3) is higher than the main conveyor belt (9); Both sides of the first-level conveyor belt (2) are 10 cm wide, so as to ensure that the aggrega...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com