Synchronous belt drive rotary prism device

A technology of rotating prisms and synchronous belts, applied in installation, optics, instruments, etc., can solve the problems of difficult to eliminate the return error and the existence of meshing gaps, and achieve the effect of compact structure, guaranteed reliability and flexible use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

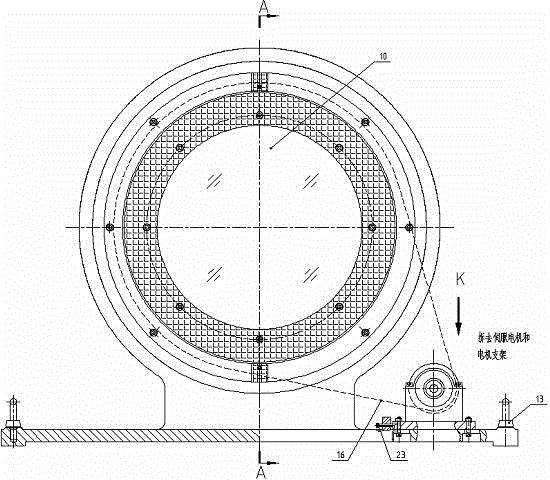

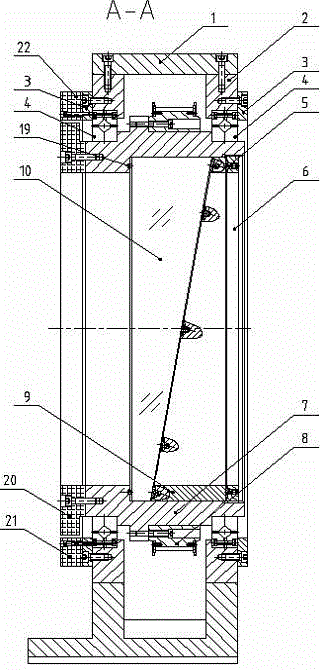

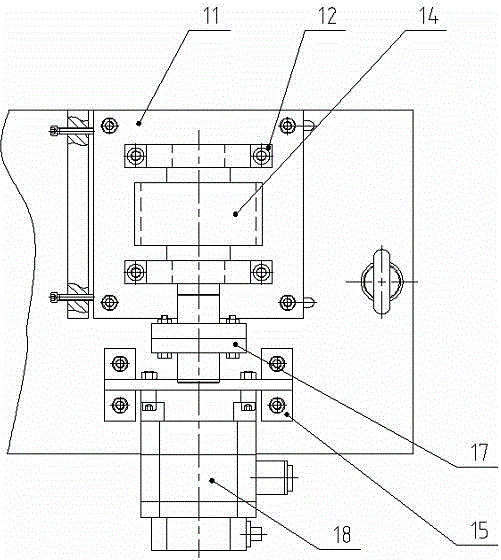

[0037] see Figure 1-Figure 4 as shown, figure 1 It is a front view of the overall structure of the rotating prism device of the present invention, figure 2 is the A-A sectional structure diagram of the overall structure of the device, image 3 for figure 1 Partial view of K direction, Figure 4 It is a structural diagram of the mirror frame and the scanning mirror assembly of the present invention. Such as Figure 4 As shown, the O-ring 19 is first placed in the circular groove on the shoulder of the mirror frame 7, and the structure of the mirror frame 7 is as follows Figure 8 Shown, put into wedge prism 10 then, the shape of wedge prism 10 is as follows Figure 9As shown, the vertical surface of the wedge prism 10 is not in direct contact with the shoulder of the mirror frame 7, but is pressed by a rubber O-ring to ensure that the wedge prism 10 is not damaged or worn. The other side of the wedge-shaped prism 10, that is, the wedge-shaped surface, is axially compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com