Color contact lens taking scales of morphidae wings as pigment and manufacture method thereof

A contact lens and morpho technology, applied in glasses/goggles, optics, instruments, etc., can solve the problems of hindering the exchange of oxygen and water molecules, affecting the appearance of the lens, and the pigment layer is easy to fall off, etc., to achieve the effect of improving color stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

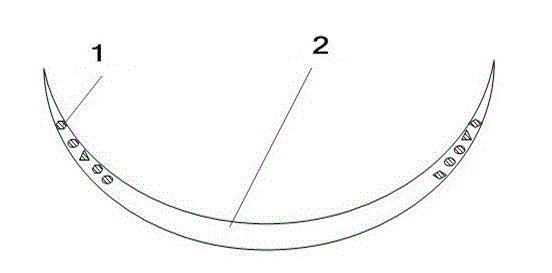

[0034] Example 1 Preparation of colored contact lenses directly using butterfly scales 1 as pigment:

[0035] 1. Acquisition of Morpho butterfly wing scale 1:

[0036] Take the brightly colored part of the Morpho butterfly's wing and smash it to get the Morpho butterfly wing scale 1;

[0037] 2. Preparation of hydrogel prepolymer solution for colored contact lenses:

[0038] The morpho butterfly scale 1 obtained in step (1) is directly used as a contact lens hydrogel to add pigment, and it is mixed into the hydrogel prepolymer solution of the contact lens body to obtain a colored contact lens hydrogel prepolymer solution.

[0039] 3. Curing steps of lens 2 with flake 1 as pigment:

[0040] The colored contact lens hydrogel prepolymer solution obtained in step (2) is dotted on the iris area of the lens 2 mold, and the lens 2 is obtained after ultraviolet or thermal polymerization.

Embodiment 2

[0041] Example 2 Preparation of colored contact lenses with butterfly scales 1 after hydrophilic treatment as pigment:

[0042] 1. Obtaining Morpho Butterfly Wing Scale 1:

[0043] Take the brightly colored part of the Morpho butterfly's wing and smash it to get the Morpho butterfly wing scale 1.

[0044] 2. Preparation of hydrogel prepolymer solution for colored contact lenses:

[0045] The morpho butterfly scale 1 obtained in step (1) is used after surface hydrophilic treatment, and mixed into the hydrogel prepolymer solution of the contact lens body to obtain the hydrogel prepolymer solution of the colored contact lens.

[0046] 3. Curing steps of lens 2 with flake 1 as pigment:

[0047] The colored contact lens hydrogel prepolymer solution obtained in step (2) is dotted on the iris area of the lens 2 mold, and the lens 2 is obtained after ultraviolet or thermal polymerization.

Embodiment 3

[0048] Example 3 Performance test of colored contact lenses using butterfly wing scale 1 as pigment:

[0049] 1. Light transmission test:

[0050] The color contact lens with butterfly wing scale 1 as the pigment was selected as the test object, and the light transmittance test was carried out on the pupil area, and the result showed that the light transmittance of white light was above 95%;

[0051] 2. Water content test:

[0052] After the contact lens material is saturated with water, the moisture accounts for 42%-60% of the total weight, and the lens 2 belongs to the lens 2 containing medium water.

[0053] 3. Lens 2 Center Thickness Test:

[0054] The central pupil area of the lens 2 was selected, and its thickness was measured to be 0.06 mm. The result showed that the lens 2 belonged to a medium-standard lens 2 .

[0055] 4. Cytotoxicity test of lenses:

[0056] The test adopts the ISO9363-1 method to observe the safety performance of lens 2 by examining the cytoto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com