Knitting machine oil additive, preparation method thereof and knitting machine oil

A knitting machine oil and additive technology, which is applied in the field of lubricating oil, can solve problems such as dark color of knitting machine oil, poor color stability, and affecting fabric quality, and achieve good extreme pressure and wear resistance, good stability, and time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

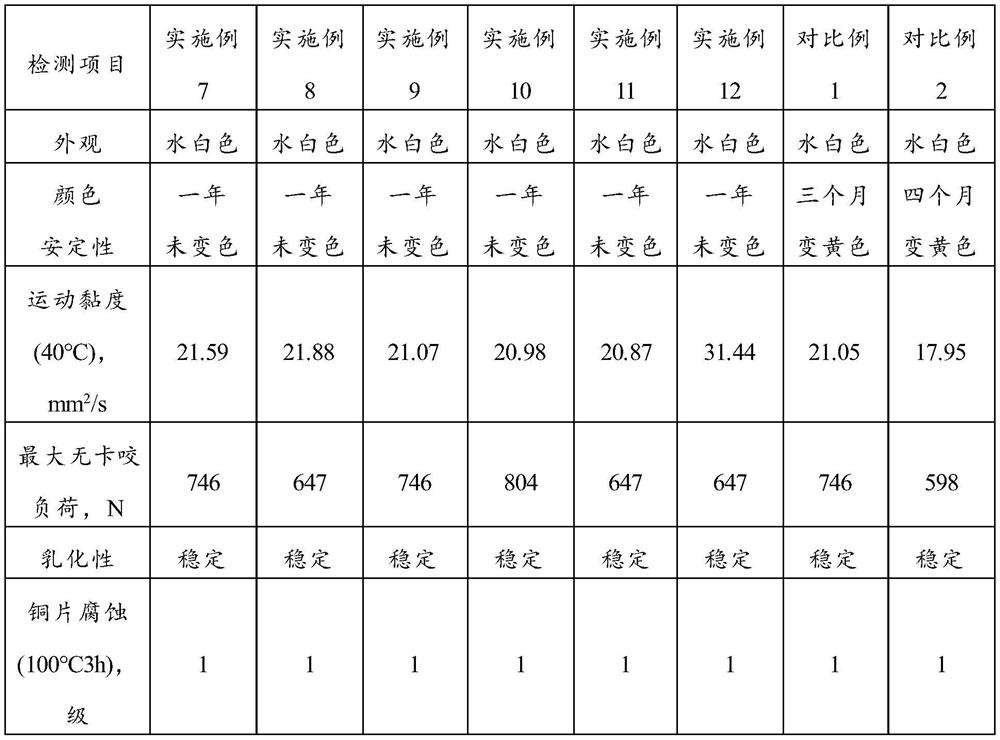

Examples

Embodiment 1

[0094] The knitting machine oil additive provided in this embodiment includes A component and B component that are individually packaged and have a mass ratio of 33.3:1;

[0095] Wherein, the A component is mainly made of the following components in parts by weight: 5 parts of di-tert-butyl-p-cresol, 1 part of sorbitol monoglyceride, sorbitan fatty acid ester (HLB value is 8-18) 25 parts and sorbitan fatty acid ester (HLB value 1-7) 69 parts;

[0096] The B component is mainly made of the following components in parts by weight: 37 parts of phosphoric acid ester and 63 parts of benzotriazole derivatives.

[0097] The preparation method of the knitting machine oil additive provided in this example includes the following steps: put the raw materials in the A component into the reactor, and stir for 1 hour to obtain the A component; put the B component in the reactor, After stirring for 1 h, component B was obtained.

Embodiment 2

[0099] The knitting machine oil additive provided in this embodiment includes A component and B component that are individually packaged and have a mass ratio of 33.3:1;

[0100] Wherein, the A component is mainly made of the following components in parts by weight: 6.8 parts of 2,6-di-tert-butyl mixed phenol, 0.4 part of dodecenylsuccinic acid, polyoxyethylene sorbitol anhydride 41.5 parts of fatty acid esters (HLB value 8-18) and 51.3 parts of ethoxylated propoxylated fatty alcohols (HLB value 1-7);

[0101]The B component is mainly made of the following components in parts by weight: 30.5 parts of phosphite and 69.5 parts of thiadiazole derivatives.

[0102] The preparation method of the knitting machine oil additive provided in this example comprises the following steps: putting each raw material in component A into a reactor, stirring for 3 hours to obtain component A; putting each raw material in component B into a reactor, After stirring for 1 h, component B was obtain...

Embodiment 3

[0104] The knitting machine oil additive provided in this embodiment includes A component and B component that are individually packaged and have a mass ratio of 33.3:1;

[0105] Among them, the A component is mainly made of the following components in parts by weight: 3.5 parts of liquid high molecular weight phenol, 0.65 parts of dodecenyl succinic acid half ester, ethoxylated propoxylated 33.5 parts of fatty alcohol (HLB value 8-18) and 62.35 parts of alkoxylated fatty alcohol (HLB value 1-7);

[0106] The B component is mainly made of the following components in parts by weight: 33.5 parts of phosphate ester amine salt and 66.5 parts of thiadiazole derivatives.

[0107] The preparation method of the knitting machine oil additive provided in this example comprises the following steps: putting each raw material in component A into a reactor, stirring for 2 hours to obtain component A; putting each raw material in component B into the reactor, After stirring for 2 h, compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com