Manufacturing method of color film substrate, color film substrate and display device

A color filter substrate and manufacturing method technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of wasting materials, increasing manufacturing costs, increasing process steps and time, and reducing the number of times and time, reducing manufacturing costs, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

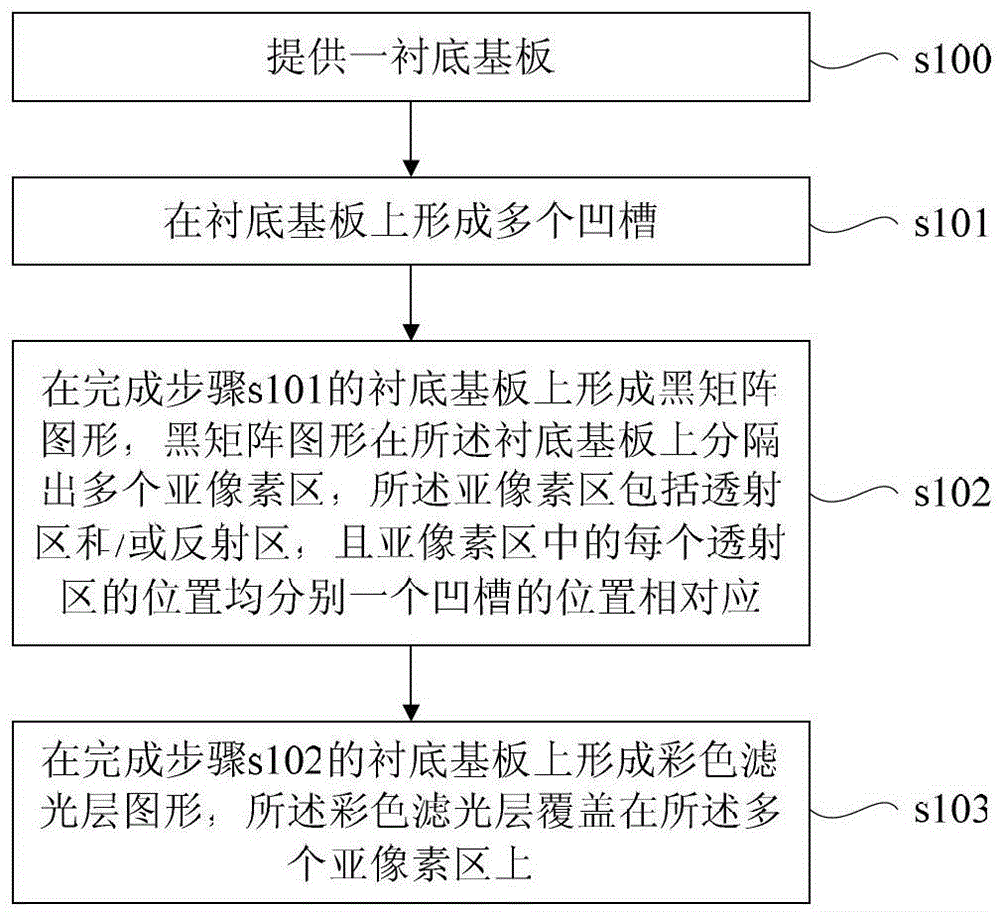

[0046] Such as figure 1 As shown, this embodiment provides a method for manufacturing a color filter substrate, including the following steps:

[0047] s100. Providing a base substrate.

[0048] The base substrate should be clean and free of dust and impurity ions. The base substrate can be transparent substrates such as glass substrates, quartz substrates, and plastic substrates.

[0049] s101. Forming a plurality of grooves on the base substrate.

[0050] The method for forming the plurality of grooves specifically includes: coating a layer of photoresist on the base substrate, exposing and developing the photoresist by using a mask to form a photoresist layer on the base substrate. The glue retaining area and the photoresist removal area, wherein, the photoresist removal area corresponds to the area of the plurality of grooves, then the exposed base substrate is etched, and finally the remaining photoresist is removed by the photoresist stripping process. The resist i...

Embodiment 2

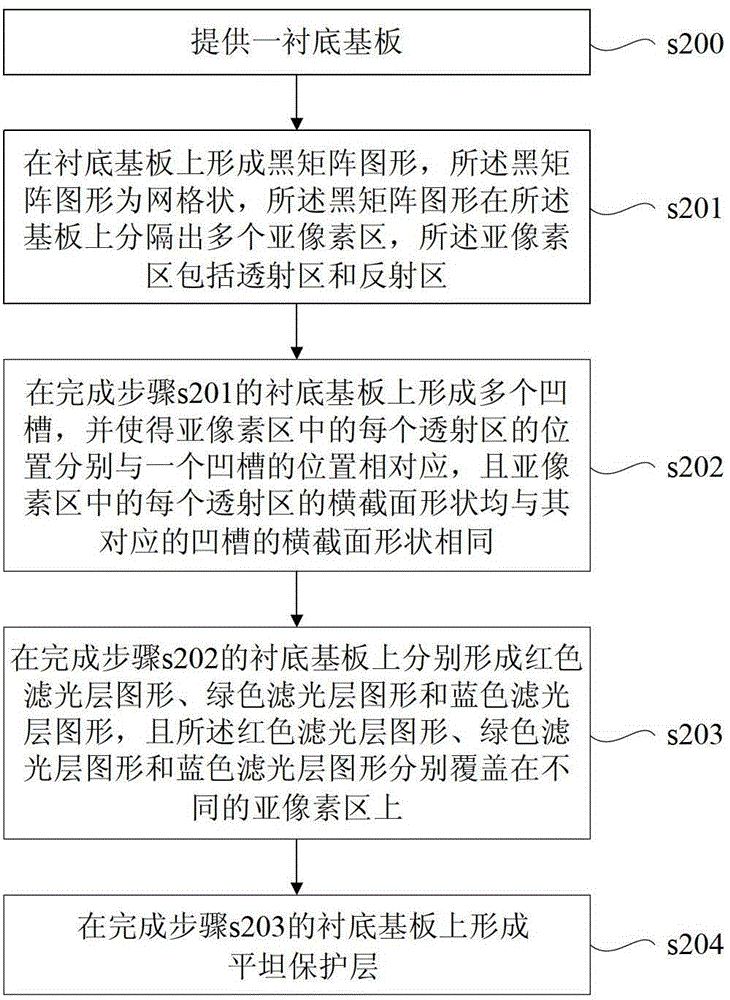

[0062] Such as figure 2 As shown, this embodiment provides a method for manufacturing a color filter substrate, including the following steps:

[0063] s200. Providing a base substrate.

[0064] The base substrate should be clean and free of dust and impurity ions. The base substrate can be transparent substrates such as glass substrates, quartz substrates, and plastic substrates.

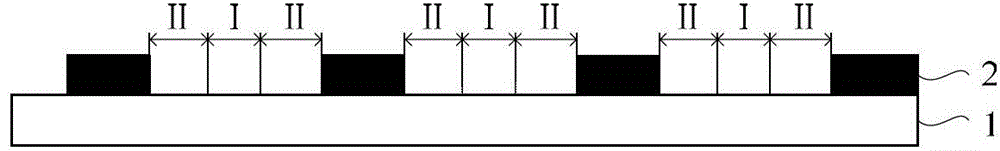

[0065] s201. Forming a black matrix pattern on the base substrate, the black matrix pattern is grid-like, and the black matrix pattern separates a plurality of sub-pixel regions on the base substrate, and the sub-pixel regions include a transmission region and reflective areas. The structure of the color filter substrate that completes this step is as follows image 3 As shown, in this embodiment, the reflective region II in the sub-pixel region is located around and surrounds the transmissive region I, so as to achieve a better display effect.

[0066] Specifically, taking metal materials as...

Embodiment 3

[0094] This embodiment provides a color filter substrate, including a base substrate, a black matrix disposed on the base substrate, and a color filter layer. The pattern formed by the black matrix is separated into multiple The sub-pixel area, the color filter layer is covered on the plurality of sub-pixel areas, the sub-pixel area includes a transmission area and / or a reflection area, a plurality of grooves are arranged on the base substrate, and the sub-pixel The position of each transmissive area in the zone corresponds to the position of a groove respectively.

[0095] Said that the sub-pixel area includes a transmission area and / or a reflection area means: each sub-pixel area includes both a transmission area and a reflection area; or, some sub-pixel areas only include a transmission area, and some sub-pixel areas only include a transmission area. Includes reflective areas. Of course, no matter what the case is, only the position corresponding to the transmission area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com