Long-contact time micro-electromechanical universal inertia switch and manufacturing method for same

A contact time, inertia switch technology, applied in the direction of electrical switches, circuits, electrical components, etc., can solve the problems that the circuit cannot be reliably connected, short, and the contact time of the movable electrode and the fixed electrode is short, so as to improve the anti-interference performance. and reliability, extended contact time, reliable switching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

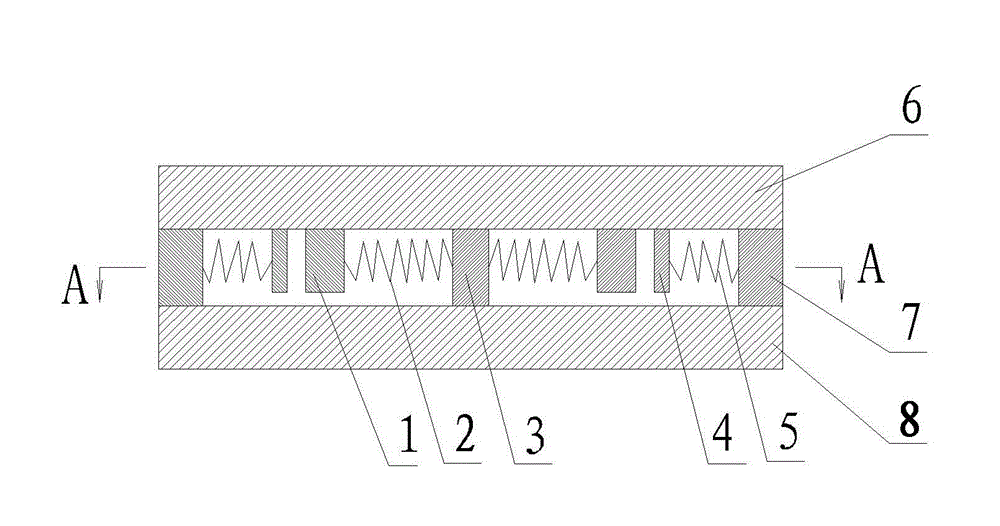

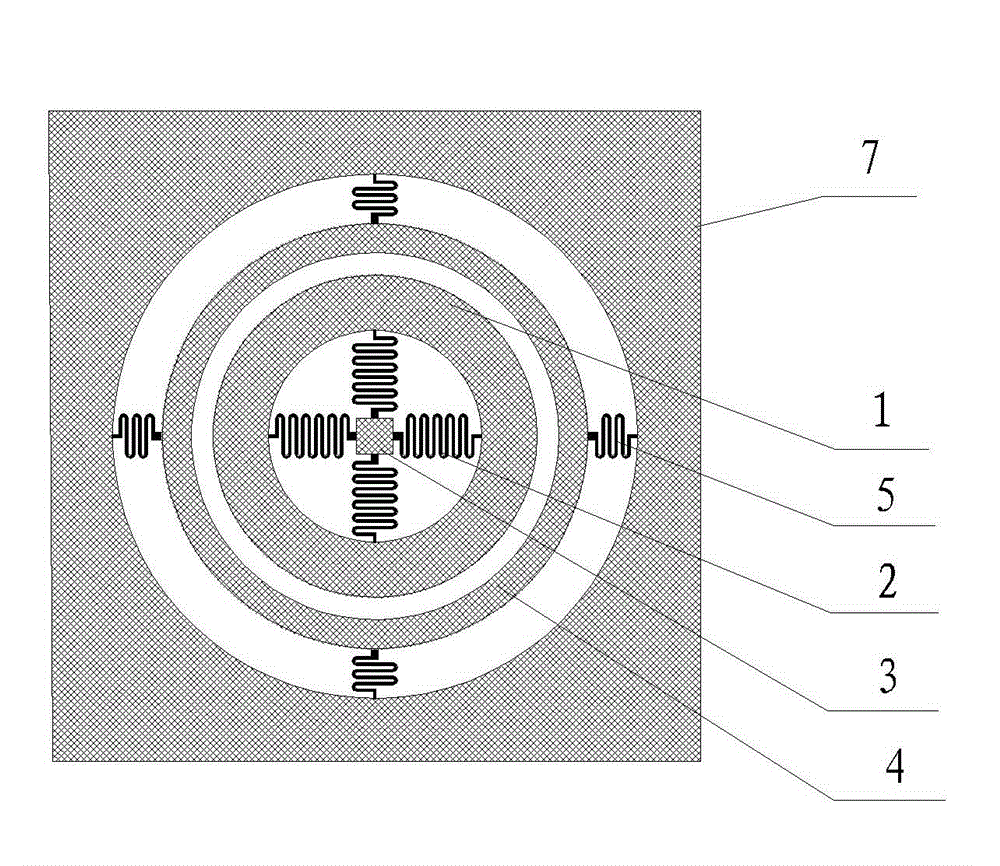

[0011] see figure 1 , which includes an upper cover plate 6, a lower cover plate 8 and a silicon chip intermediate structure layer, the said upper cover plate is a silicon plate; see figure 2 , the middle structure layer of the silicon wafer is, with the anchor point 3 as the center of the circle, there are ring-shaped quality frame 1, ring-shaped outer electrode 4 and anchor area 7 in sequence, and the anchor area is in the shape of a plane frame with an outer square and an inner circle, wherein the anchor area and the anchor point Bonded with the upper and lower cover plates, the four outer springs 5 (constituting the outer spring frame) are arranged in a cross shape, and the two ends of each outer spring are respectively fixed between the anchor area and the ring-shaped outer electrode, and the four inner springs 2 ( The inner spring frame) is arranged in a cross shape, and the two ends of each inner spring are respectively fixed on the annular mass frame and the anchor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com