Light-emitting diode (LED) power source with inversed LED chip and method for producing LED power source with inversed LED chip

A technology of LED chip and LED light source, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of insignificant improvement of reflective effect and low light transmittance, reduce the complexity of the preparation process, improve the light extraction efficiency, The effect of consistency guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

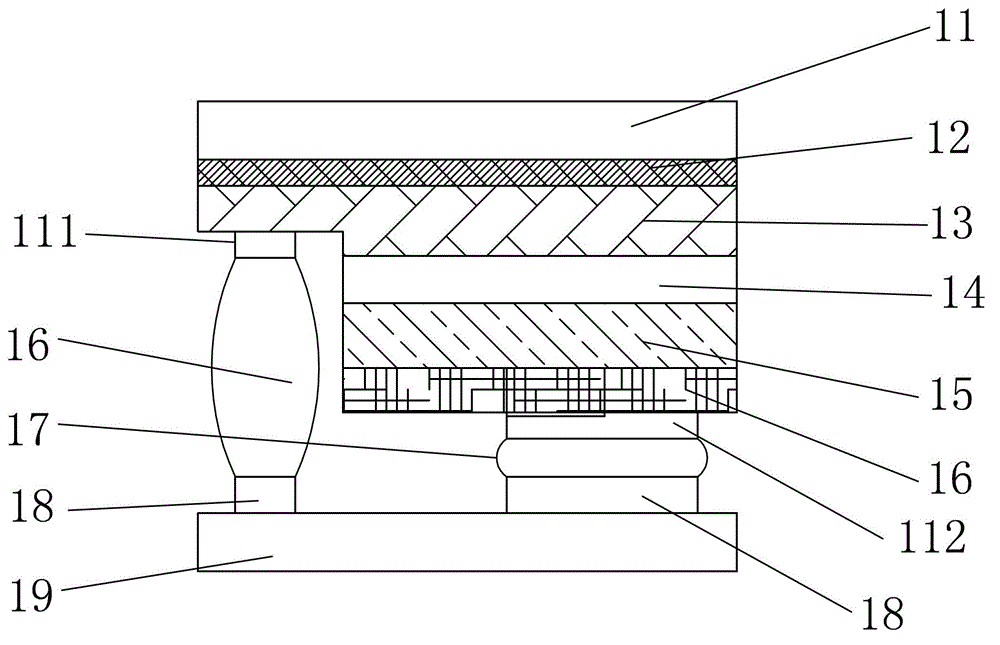

[0039] see image 3 , the LED light source described in the figure includes an LED chip and a substrate 19; the LED chip includes a transparent substrate 11, an N-type cladding layer 13, an active layer 14, a P-type cladding layer 15, a transparent Conductive film layer 16. Wherein, the active layer 14 is a single layer or MQW layer structure.

[0040] An N-type electrode plate 111 is provided on the exposed area of the N-type cladding layer 13, and a metal bump 16 is provided on the N-type electrode plate 111; a P-type electrode plate is provided on the transparent conductive film layer 16. An electrode pad 112 , the P-type electrode pad 112 is provided with metal bumps 17 .

[0041] The substrate 19 is a transparent substrate, on which a metal boss 18 and positive and negative electrodes (not shown) for connecting to an external circuit are provided; the metal bump on the N-type electrode plate 111 16 and the metal bumps 17 on the P-type electrode plate 112 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com