Sunken type metal base electric resistance welding minitype quartz-crystal resonator

A metal base and quartz crystal technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of poor air tightness, high cost, broken glass insulators, etc., and achieve convenient processing and manufacturing, good air tightness, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The recessed metal base resistance-welded miniature quartz crystal resonator of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

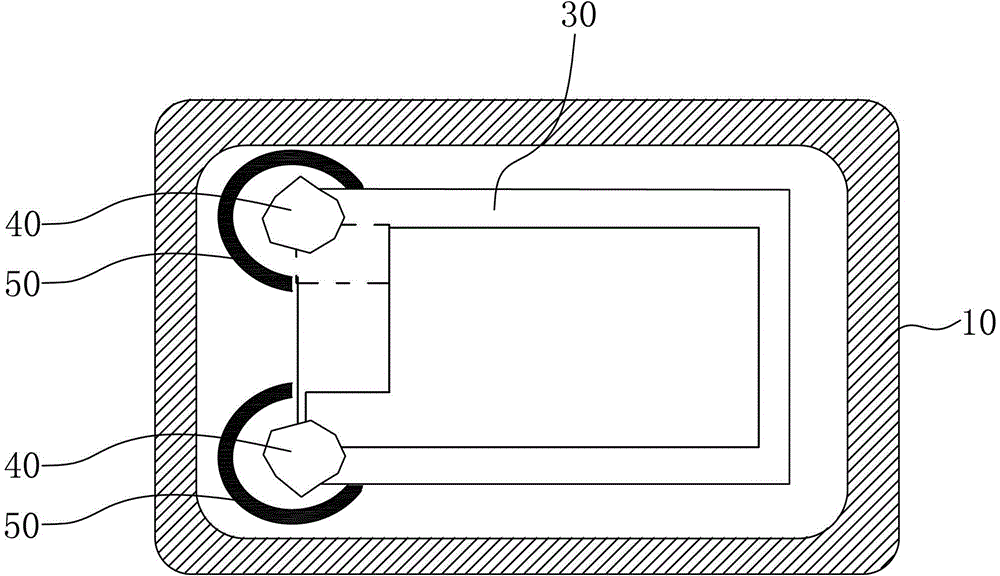

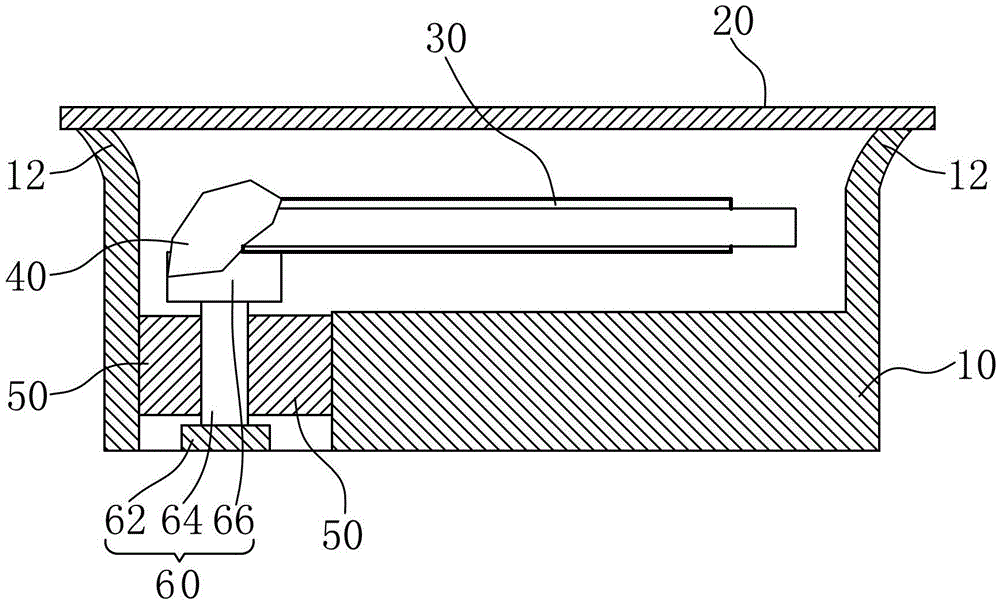

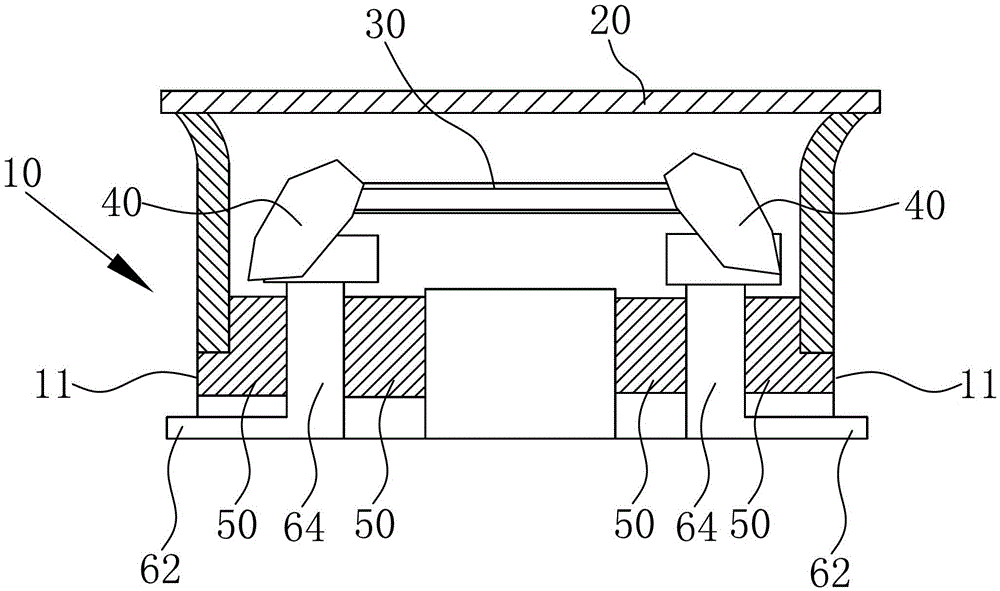

[0028] See Figure 1 to Figure 6 Shown, a kind of concave type metal base resistance welding miniature quartz crystal resonator of the embodiment of the present invention, this quartz crystal resonator comprises metal base 10, cover plate 20, silver electrode crystal plate 30, conductive glue 40, glass insulation Seed 50, lead terminal 60, the metal base 10 is a structure with a cavity space, the upper edge 12 of the metal base 10 extends outwards, so that the entire metal base 10 forms a concave cavity space structure, the upper edge 12 and The cover sheet 20 is sealed and welded, the bottom of the concave metal base 10 and the glass insulating seed 50 form a concave surface, and the silver electrode crystal 30 is in the concave cavity.

[0029] The metal base 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com