Copper alloy hot-forged part and process for producing copper alloy hot-forged part

A manufacturing method and technology of hot forgings, which are applied in the field of manufacturing copper alloy hot forgings and copper alloy hot forgings, and can solve problems such as poor electrical/thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

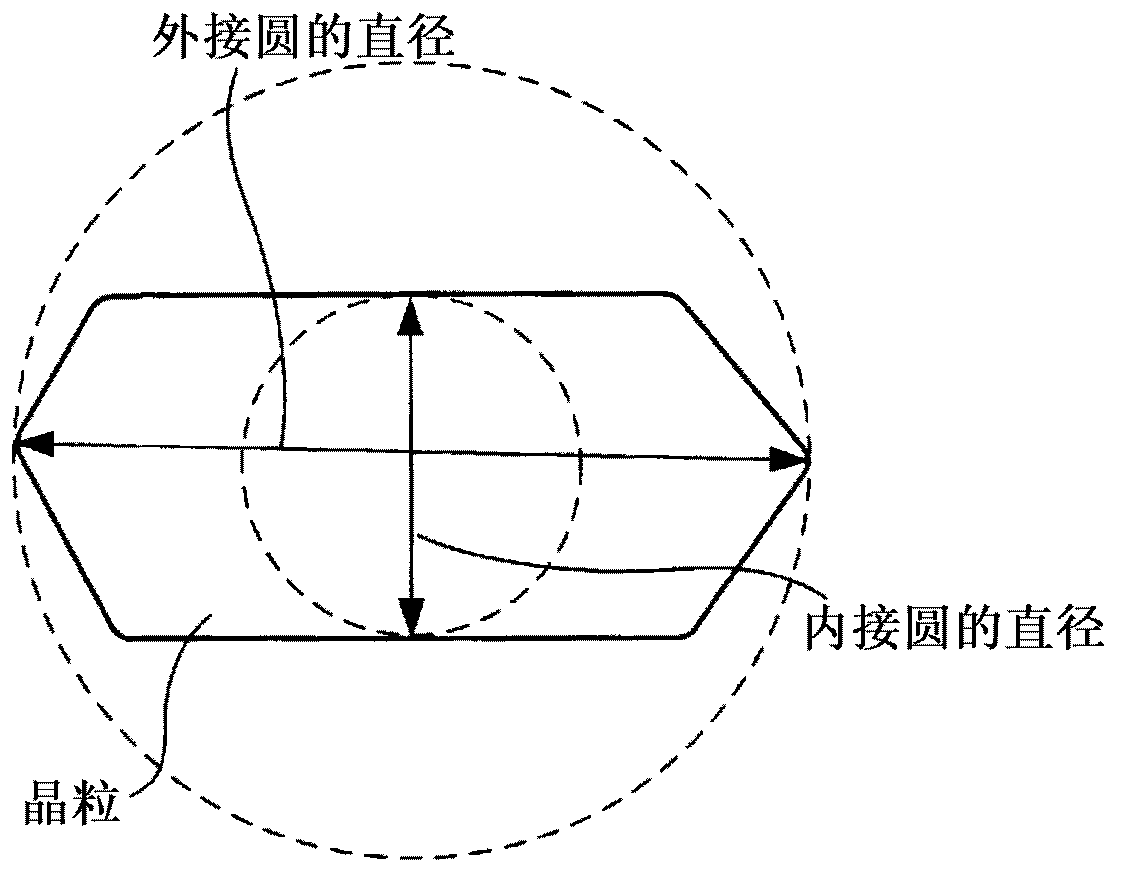

Image

Examples

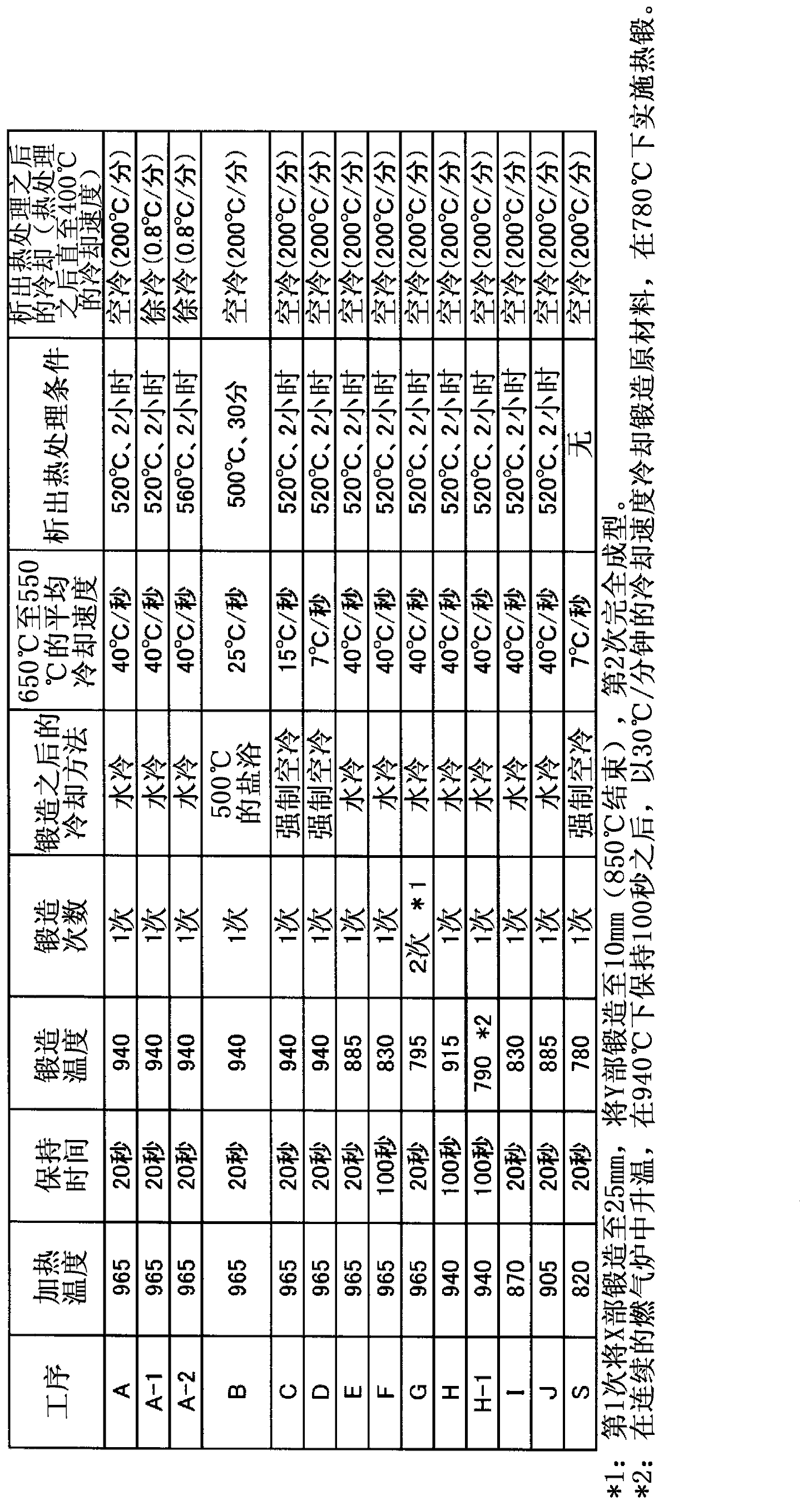

Embodiment Construction

[0060] The copper alloy hot forging according to the embodiment of the present invention will be described.

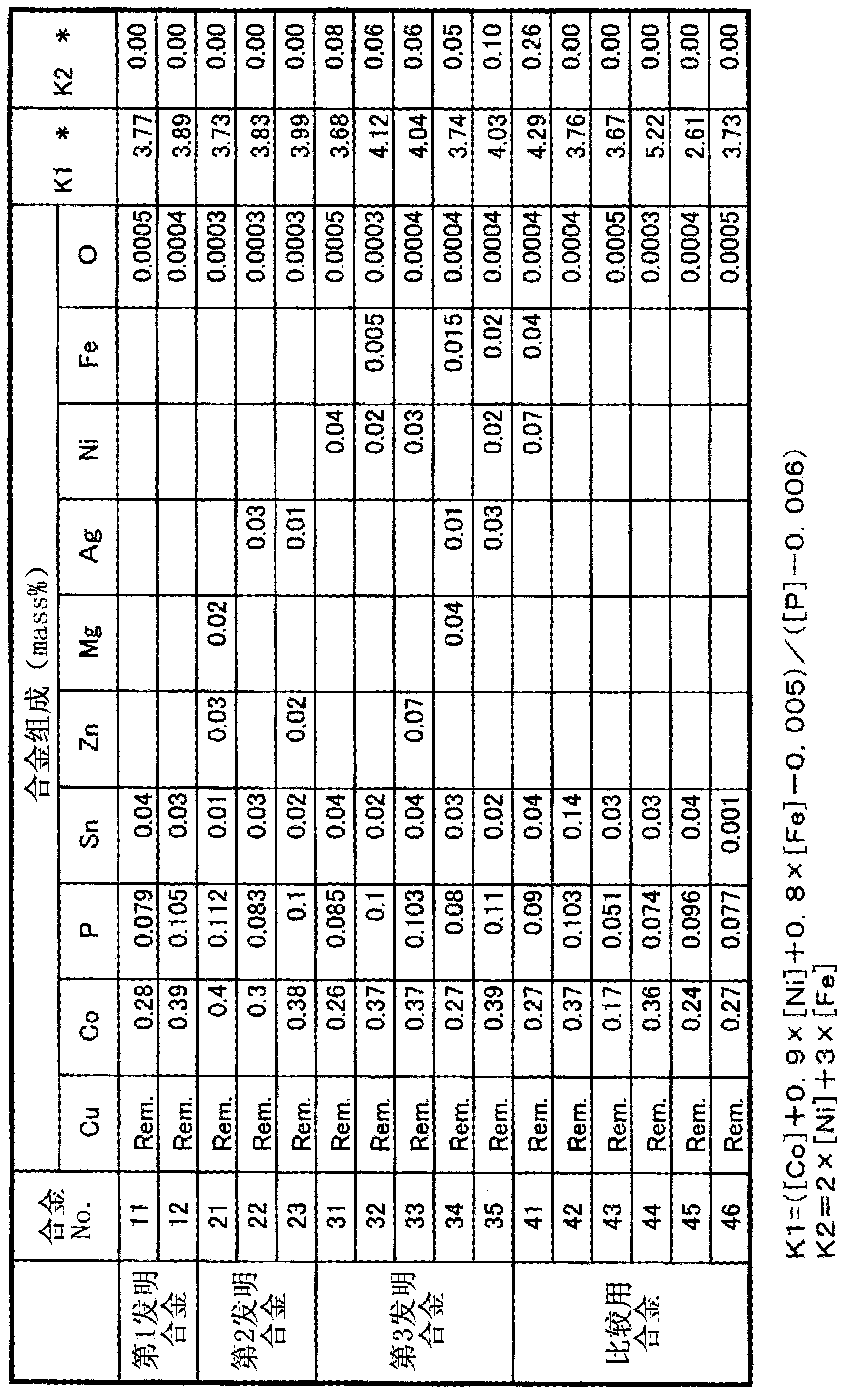

[0061]As the copper alloy of the present invention, the alloys of the first invention to the alloys of the third invention are proposed. In order to indicate the alloy composition, the symbol of an element enclosed in [] brackets such as [Cu] in this specification is expressed as the content value (mas s%) of the element. And, using the expression method of this content value, a plurality of calculation formulas are presented in this specification, but when the element is not included in each calculation formula, it is calculated as 0. In addition, the first to third invention alloys are collectively referred to as invention alloys.

[0062] The alloy composition of the first invention alloy is 0.21 to 0.44 mass% of Co, 0.06 to 0.13 mass% of P, 0.003 to 0.08 mass% of Sn, and 0.00003 to 0.0030 mass% of O, and the remainder includes Cu and unavoidable impurities. , the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com