Live fish barrel and method of storage and transportation of live fishes through live fish barrel

A technology of live fish and cylinder cover, which is applied in application, fish farming, animal husbandry, etc. It can solve the problems of unfavorable stacking and transportation, easy damage to fish body, etc., and achieve the effect of beautiful appearance, long life preservation time and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

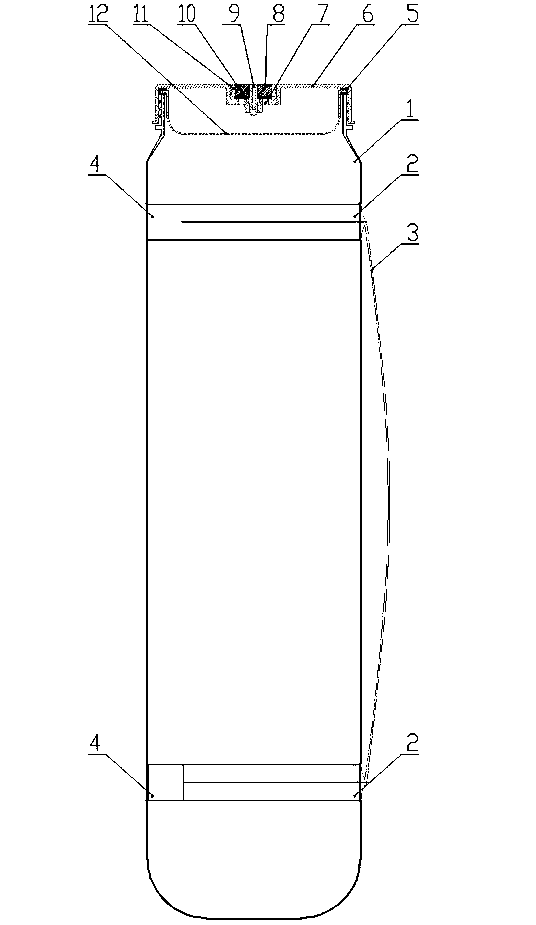

[0027] Embodiment one: a kind of live fish tube such as Figure 5 As shown, it is suitable for the packaging, transportation and sales of 2.5-3.5kg / tail commercial grass carp or other fish of similar size and specification.

[0028] The live fish cylinder body 1 is made into a cylindrical container by blow molding of transparent PET plastic, with a wall thickness of 0.8 mm, a length of 700 mm, a diameter of 180 mm, and an inner diameter of the cylinder mouth of 150 mm. External threads are provided on the outside of the cylinder mouth, and the cylinder body 1 has two Rib 16. The two ends of the handle 3 are respectively connected to two collars 2, and the collars 2 are fixed on the ribs 16, and there is an anti-roll base 4 at the bottom of the collars.

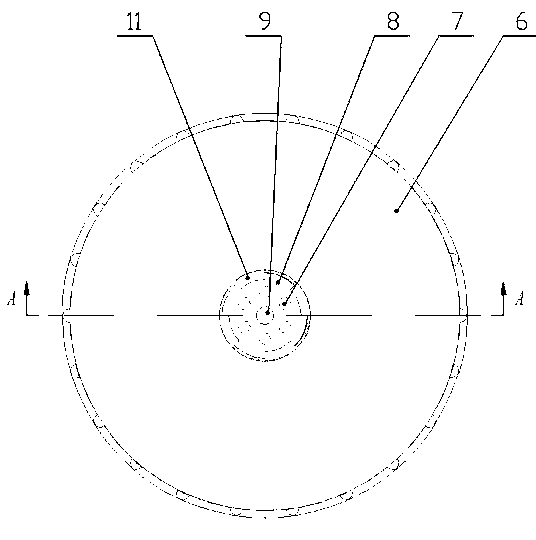

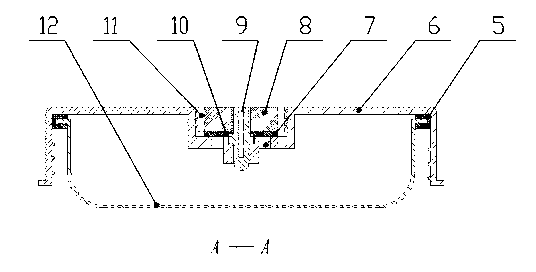

[0029] Described live fish cylinder cover 6 is as figure 2 , image 3 and Figure 4 As shown, the cylinder cover 6 is made of engineering plastic injection molding, and the inside of the cylinder cover edge has internal t...

Embodiment 2

[0034] Embodiment two: a kind of live fish tube such as Figure 7 As shown, it is suitable for the packaging and transportation of fry and fingerlings.

[0035] The live fish cylinder body 1 is made into a cuboid container with rounded corners by injection molding of transparent PC plastic, with a wall thickness of 1.2 mm, a length of 800 mm, a diameter of 200 mm, an inner diameter of the mouth of the mouth of 150 mm, and an external thread on the outside of the mouth of the mouth. Two grooves 17.

[0036] The two ends of the live fish tube handle 3 are respectively connected to two collars 2, and the collars 2 are fixed in the groove 17.

[0037] The structure of the described live fish cylinder cover 6 is the same as in Embodiment 1, wherein the filter screen 12 is 30mm high, 110mm in diameter, and 0.5mm in aperture.

[0038] The fry and fingerlings are trained by pulling nets, stored in cages for 3 to 6 hours, and then packaged. Each package contains 100,000 to 200,000 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com