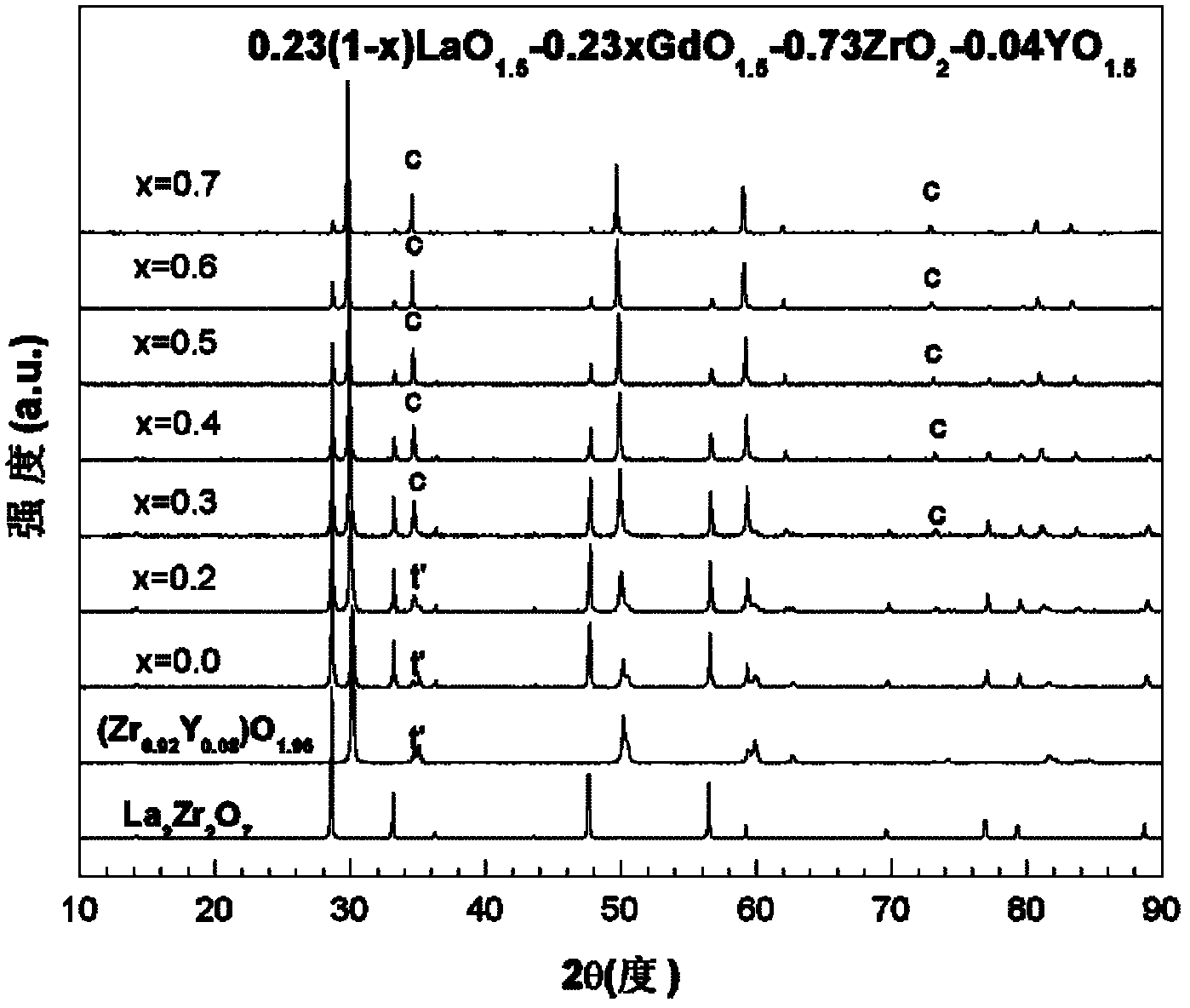

Gd2O3-modified La2Zr2O7-(Zr0.92Y0.08)O1.96 complex phase thermal barrier coating material

A thermal barrier coating, gd2o3 technology, applied in the field of La2Zr2O7-O1.96 composite thermal barrier coating heat insulation materials, can solve the problem of not meeting the requirements of thermal barrier coating, coating service temperature and thermal cycle life, YSZ phase stability decline and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

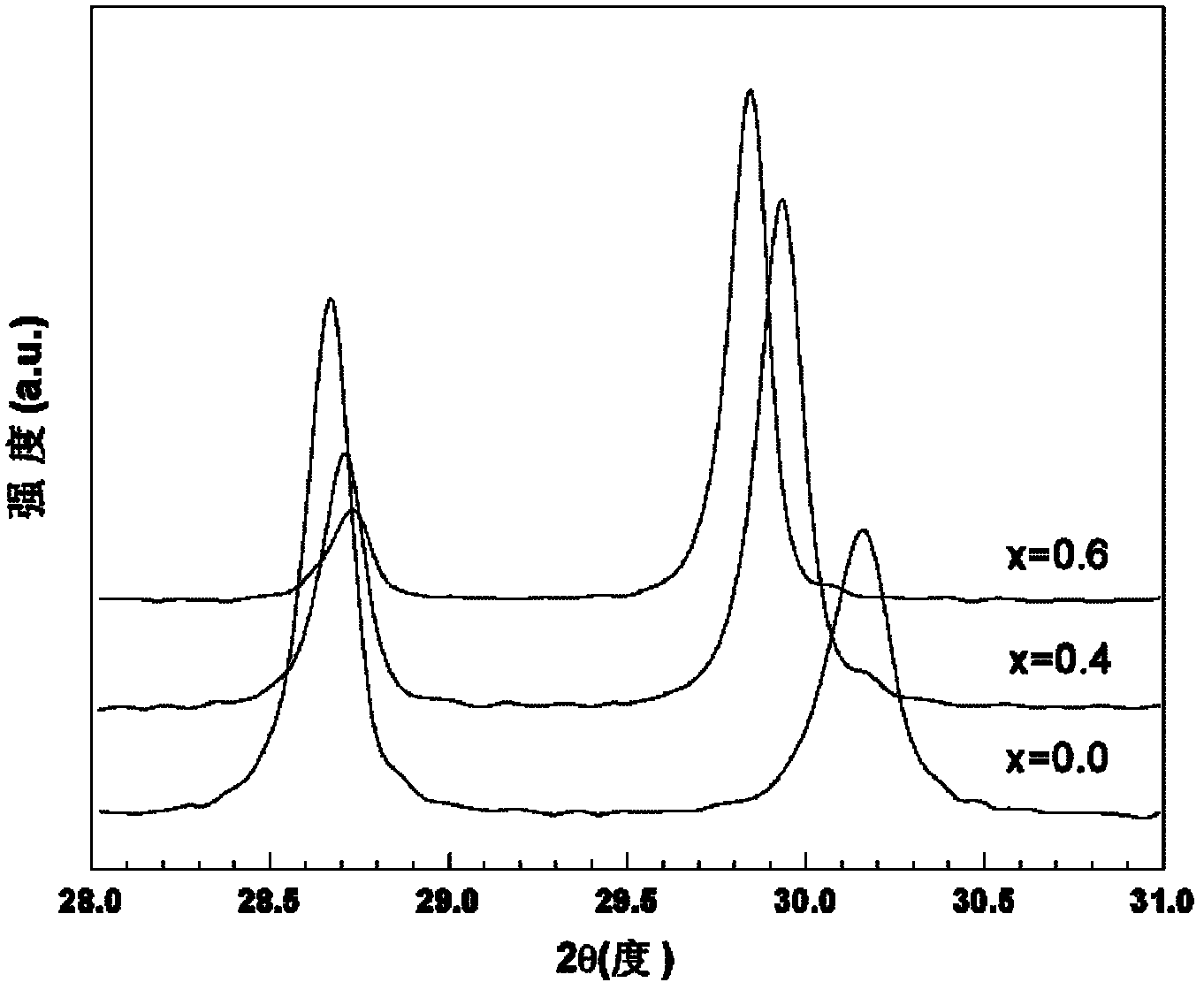

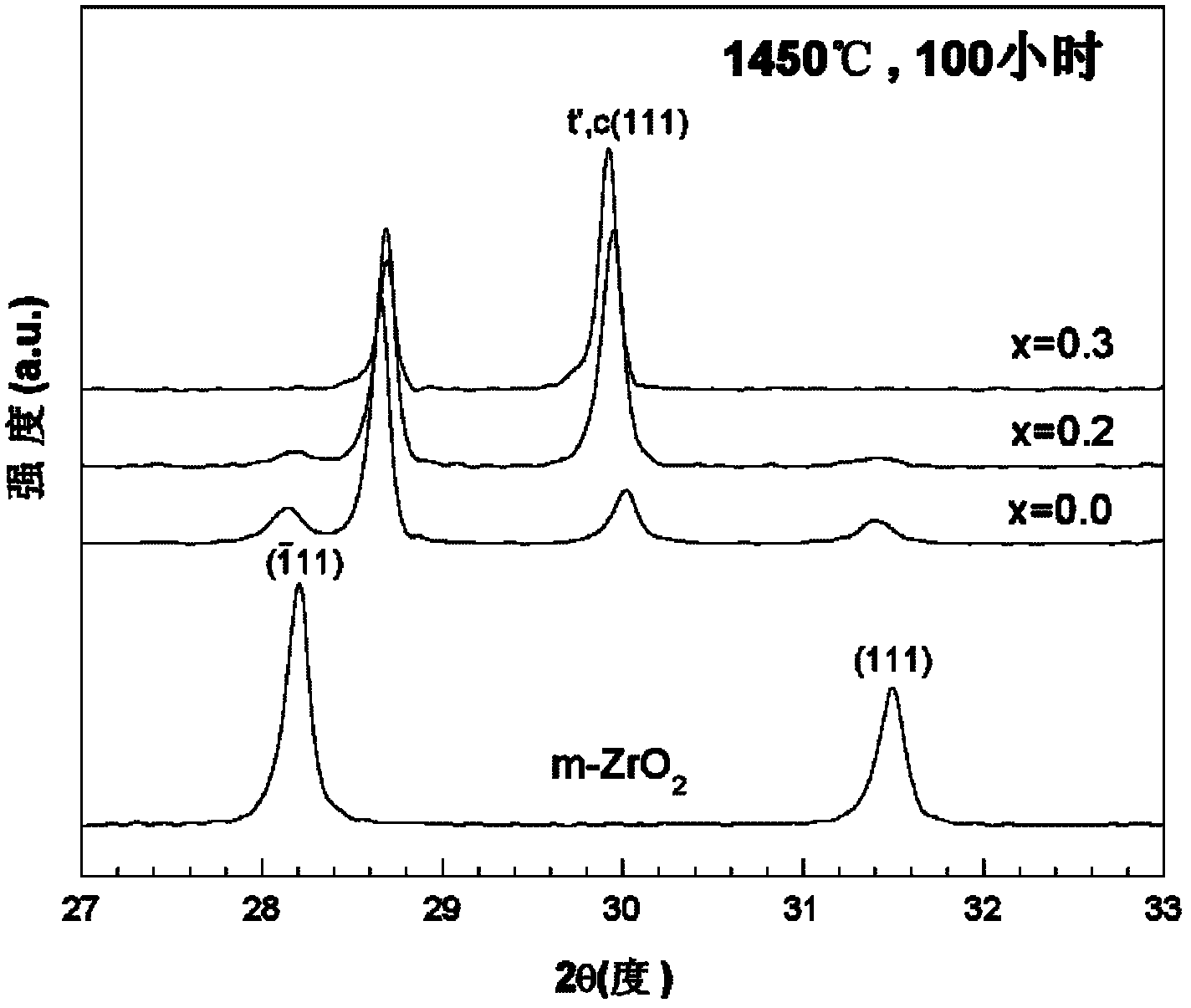

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 0.73ZrO 2 -0.184LaO 1.5 -0.046GdO 1.5 -0.04YO 1.5 Composite material

[0039] With a purity of 99.99% Ln(NO 3 ) 3 ·6H 2 O(Ln=La, Gd, Y) and Zr(NO 3 ) 4 ·3H 2 O is used as a raw material, and a standard aqueous solution with a concentration of 0.1 mol / L is prepared. Using a precision of 10 -4 The electronic balance of g accurately weighs La(NO 3 ) 3 ·6H 2 O, Y (NO 3 ) 3 ·6H 2 O, Gd(NO 3 ) 3 ·6H 2 O and Zr(NO 3 ) 4 ·3H 2 O each 43.3012g, 38.3012g, 45.1356g and 39.3289g, respectively put into 500ml of ultrapure water in a 1L glass beaker with magnetic stirring, completely dissolve and pour into a 1L standard volumetric flask, and then use 100ml Rinse the beaker with ultrapure water and pour it into a standard volumetric flask. Repeat this process for 4 times. Finally, use a 0.1ml buret to add ultrapure water dropwise until the scale of the standard volumetric flask is ready for use.

[0040] Use a burette with a capacity of 25ml and an accuracy of 0....

Embodiment 2

[0045] 0.73ZrO 2 -0.138 LaO 1.5 -0.092GdO 1.5 -0.04YO 1.5 Composite material

[0046] With a purity of 99.99% Ln(NO 3 ) 3 ·6H 2 O(Ln=La, Gd, Y) and Zr(NO 3 ) 4 ·3H 2 O is used as a raw material, and a standard aqueous solution with a concentration of 0.1 mol / L is prepared. Using a precision of 10 -4 The electronic balance of g accurately weighs La(NO 3 ) 3 ·6H 2 O, Y (NO 3 ) 3 ·6H 2 O, Gd(NO 3 ) 3 ·6H 2 O and Zr(NO 3 ) 4 ·3H 2 O each 43.3012g, 38.3012g, 45.1356g and 39.3289g, respectively put into 500ml of ultrapure water in a 1L glass beaker with magnetic stirring, completely dissolve and pour into a 1L standard volumetric flask, and then use 100ml Rinse the beaker with ultrapure water and pour it into a standard volumetric flask. Repeat this process for 4 times. Finally, use a 0.1ml buret to add ultrapure water dropwise until the scale of the standard volumetric flask is ready for use.

[0047] Use a burette with a capacity of 25ml and an accuracy of 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com