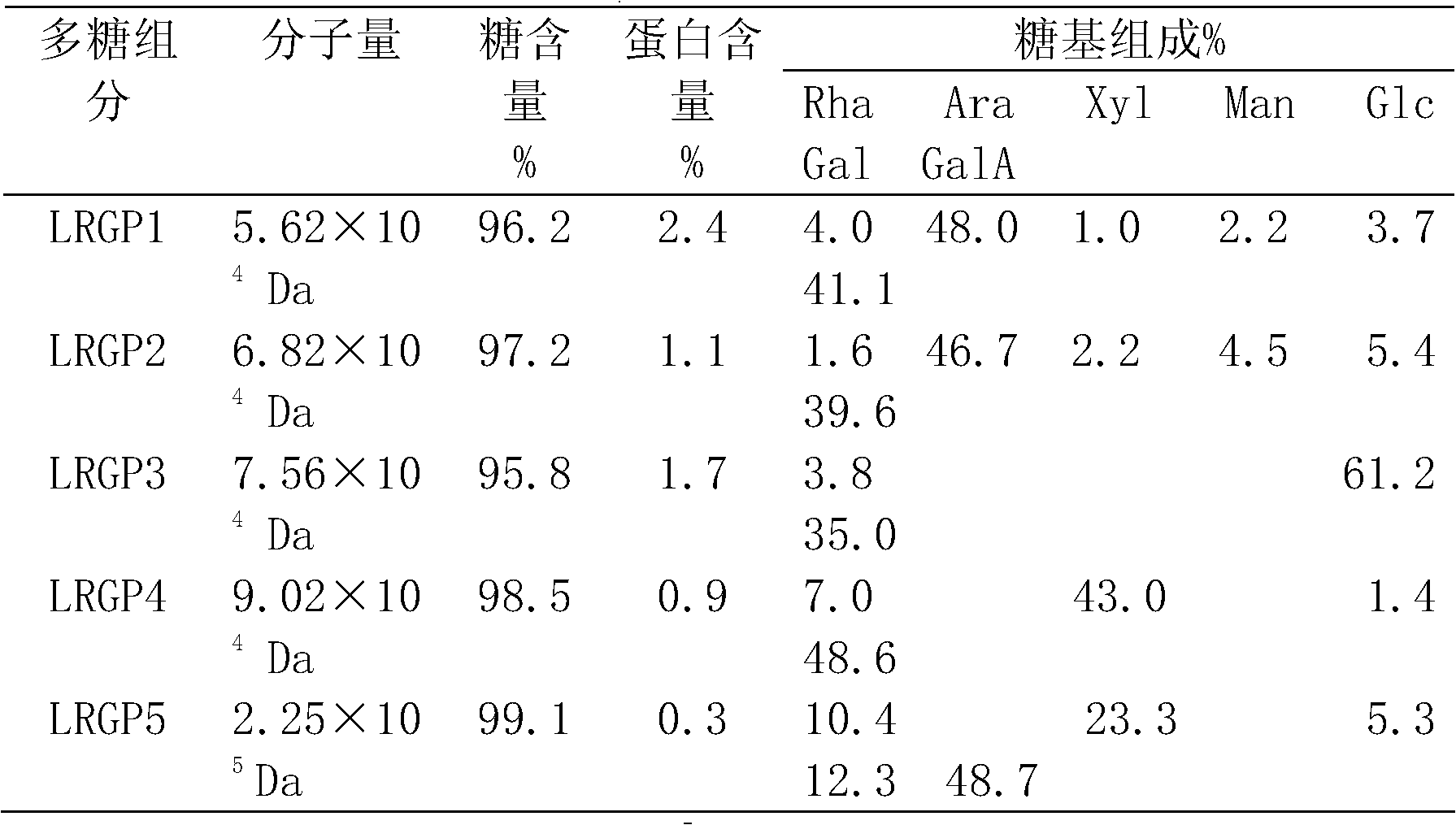

Separation and purification method of lycium ruthenicum polysaccharide and five polysaccharides obtained through separation

A technology for the separation and purification of Lycium barbarum polysaccharides, which is applied in the field of separation and purification of Lycium barbarum polysaccharides and the five kinds of polysaccharides obtained by separation, can solve the problems of shallow research, almost blank structure research of Lycium barbarum polysaccharides, and low product purity, and achieve The effect of avoiding destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

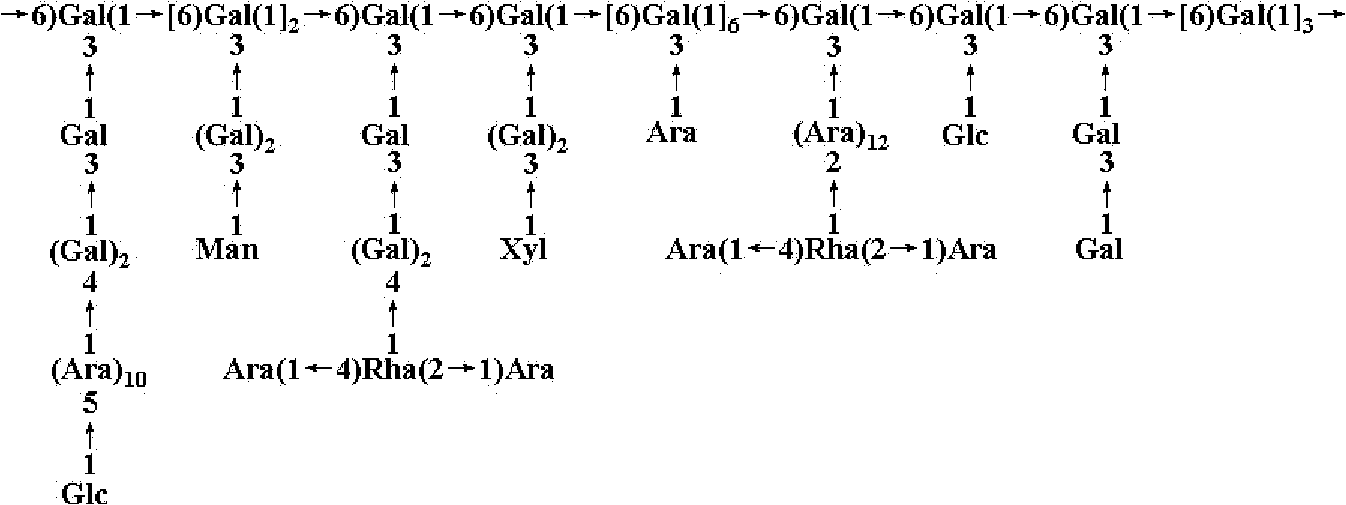

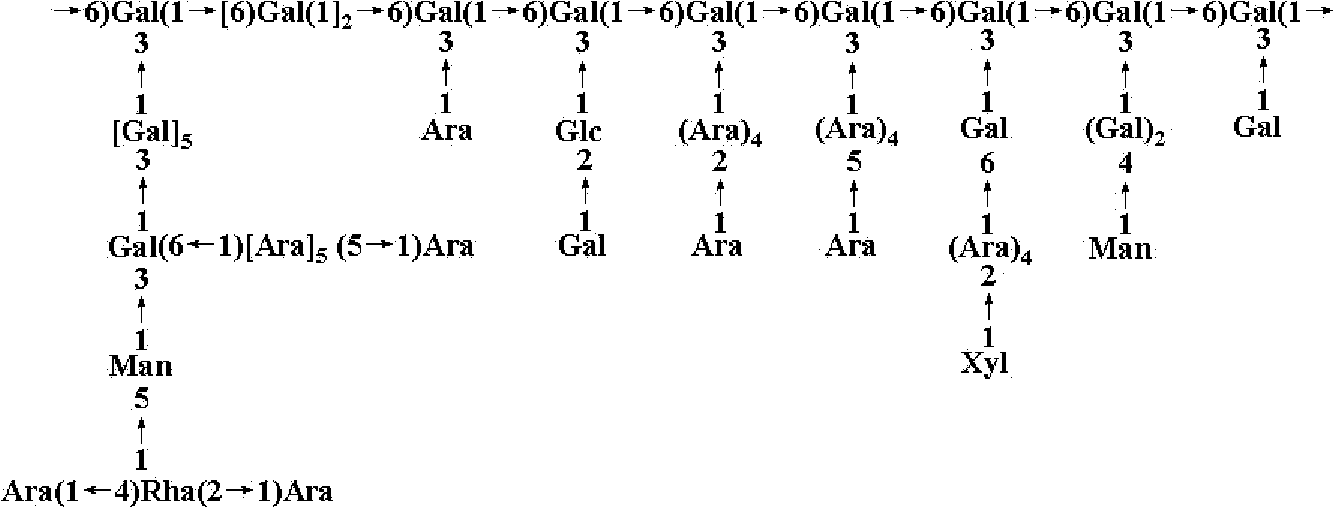

Examples

Embodiment 1

[0035] Embodiment 1 A method for isolating and purifying polysaccharides from Lycium barbarum fruit, comprising the following steps:

[0036] (1) Crushing of raw materials: add 4 times the volume of water to the fruit of Lycium ruthenicum, and grind it to a uniform state with a tissue grinder.

[0037] (2) Ultrasonic extraction: Homogenize Lycium barbarum fruit and put it into ultrasonic extraction equipment, temperature is 70°C, ultrasonic frequency is 40KHz, power is 50W, extraction time is 2h, the extract is filtered, and the residue is reheated with 2 times the volume of water for ultrasonic extraction for 1h .

[0038] (3) Alcohol precipitation: After the extract was concentrated in vacuum at 40°C, the concentration was adjusted to 80% by adding ethanol, and the polysaccharide precipitate was filtered after standing for 12 hours.

[0039] (4) Deproteinization: After dissolving the polysaccharide precipitate with water, add trichloroacetic acid to a concentration of 3%, s...

Embodiment 2

[0059] According to the extraction method described in Example 1, the difference from Example 1 is that the temperature is 50°C, the ultrasonic frequency is 40KHz, the power is 50W, the extraction time is 2h, and the yield of crude polysaccharide (LRP) is 1.2%.

Embodiment 3

[0061] According to the extraction method described in Example 1, the difference from Example 1 is that the temperature is 70°C, the ultrasonic frequency is 80KHz, the power is 50W, the extraction time is 2h, and the yield of crude polysaccharide (LRP) is 0.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com