Lycopene extract and extraction process for lycopene

An extraction process, lycopene technology, applied in food science, azo dyes, organic dyes, etc., can solve the problems of low extraction rate and low purity, achieve high pigment extraction rate, high extraction efficiency, and good water solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

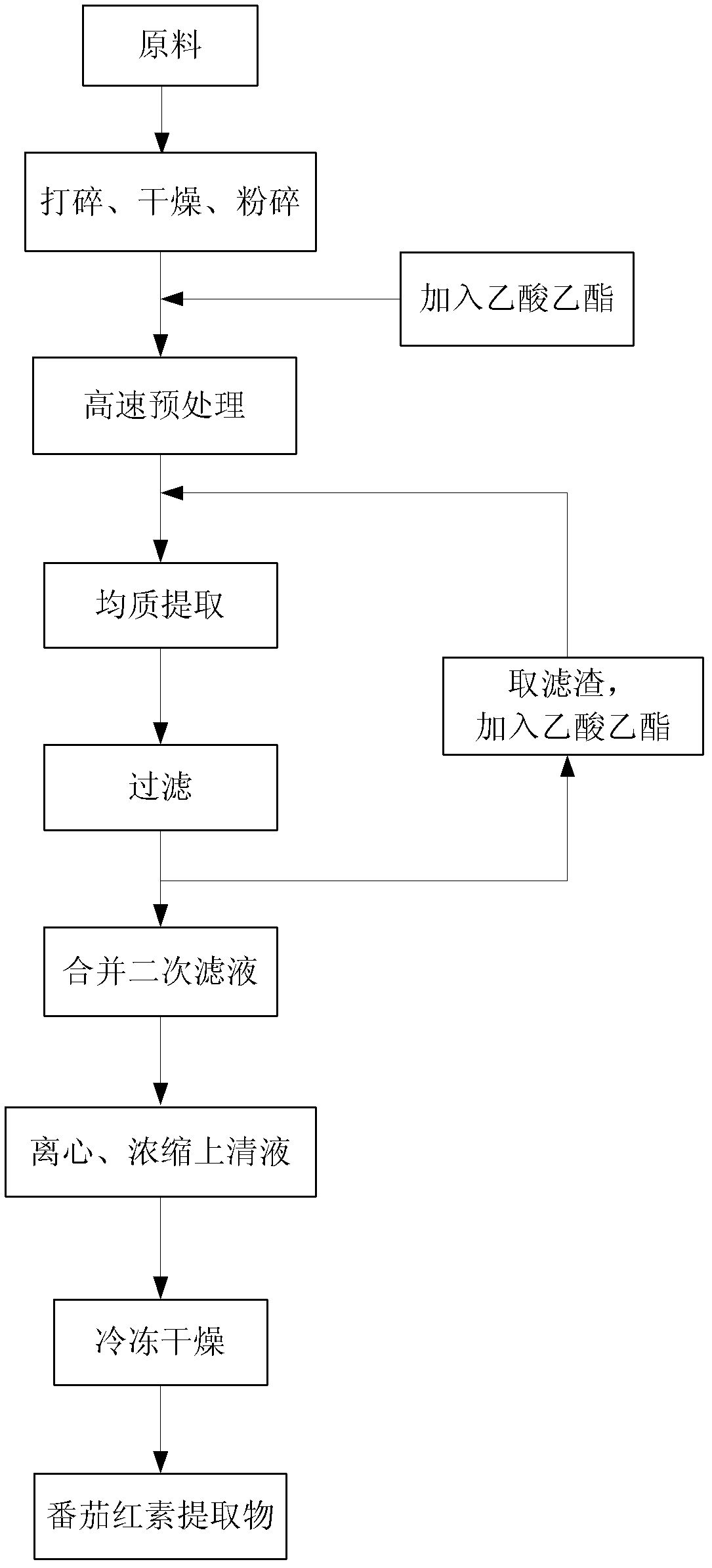

Method used

Image

Examples

Embodiment 1

[0037] 1) Take fresh tomatoes, crush them with a fruit juice machine, dry them, and crush them to 50 mesh to obtain tomato powder for later use.

[0038] 2) Weigh 100 grams of tomato powder, add 300 milliliters of ethyl acetate, pretreat at 10,000 rpm for 5 minutes at 25° C., and extract homogeneously at 3,000 rpm for 10 minutes before filtering.

[0039] 3) Mix the filter residue in the above step 2) with 300 ml of ethyl acetate, extract homogeneously at 3000 rpm for another 20 minutes at 25° C., and filter.

[0040] 4) Combine the two filtrates, centrifuge at 1000 rpm for 10 minutes, remove the precipitate, and collect the supernatant.

[0041] 5) Concentrate in vacuo and freeze-dry to form a powder to obtain 12.08 mg of crude lycopene (color: bright red), including 64.8 mg of lycopene, with an extraction rate of 98.6%.

Embodiment 2

[0043] 1) Take fresh tomatoes, crush them with a fruit juice machine, dry them, and crush them to 50 mesh to obtain tomato powder for later use.

[0044] 2) Weigh 100 grams of tomato powder, add 500 milliliters of ethyl acetate, pretreat at 9,000 rpm for 10 minutes at 25° C., extract homogeneously at 4,000 rpm for 10 minutes, and then filter.

[0045] 3) Mix the filter residue in the above step 2) with 500 ml of ethyl acetate, extract homogeneously at 4000 rpm for 10 minutes at 25° C., and filter.

[0046] 4) Combine the two filtrates, centrifuge at 2000 rpm for 5 minutes, remove the precipitate, and collect the supernatant.

[0047] 5) Concentrate in vacuo and freeze-dry into powder to obtain 121.3 mg of crude lycopene (color: bright red), including 65.3 mg of lycopene, with an extraction rate of 98.8%.

Embodiment 3

[0049] 1) Take fresh tomatoes, crush them with a fruit juice machine, dry them, and crush them to 50 mesh, and set aside.

[0050]2) Weigh 100 grams of tomato pulp (same as above, same as above), add 1000 ml of ethyl acetate, pretreat at 10,000 rpm at 25°C for 10 minutes at high speed, then extract homogeneously at 1,000 rpm for 30 minutes and then filter .

[0051] 3) Mix the filter residue in the above step 2) with 1000 ml of ethyl acetate, extract homogeneously at 1000 rpm for 30 minutes at 25° C., and filter.

[0052] 4) Combine the two filtrates, centrifuge at 500 rpm for 15 minutes, remove the precipitate, and collect the supernatant.

[0053] 5) Concentrate in vacuo and freeze-dry into powder to obtain 118.5 mg of crude lycopene (color: bright red), including 64.1 mg of lycopene, with an extraction rate of 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com