Production method of propylene and gasoline with high-octane rating

A technology for high-octane gasoline and propylene, applied in the field of hydrocarbon oil processing, to achieve efficient utilization, improve cracking performance, increase conversion rate and light oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

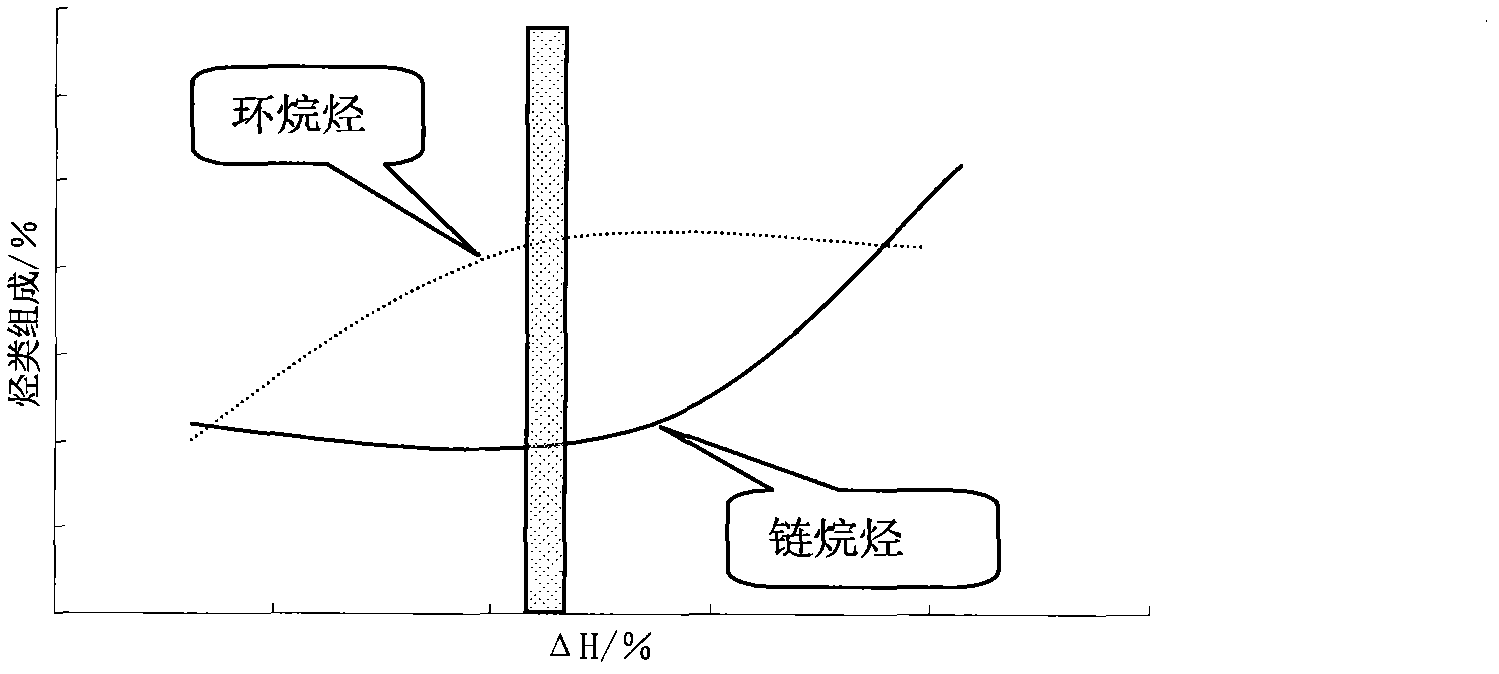

[0024] The catalytic cracking heavy oil is mixed with hydrogen, and then reacted with hydrogenation protection agent, hydrogenation deasphaltenation agent and hydrofinishing agent successively. See Table 3 for the process conditions of catalytic cracking heavy oil hydrogenation and the properties of the produced oil. See Table 4 for the process conditions, product distribution and gasoline properties of the catalytic cracking unit. It can be seen from Table 3 and Table 4 that after catalytic cracking heavy oil is hydrotreated, the resulting oil ΔH (increased hydrogen content) is 1.50%, and the naphthene content is 45.0% by weight. The gasoline yield is 6.25%, the gasoline yield is 57.90%, and the gasoline octane number (RON) is 93.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap