Steep coal seam section coal pillar roadside filling method

A section coal pillar and steeply inclined technology, which is applied in the direction of filling, earthwork drilling, safety devices, etc., can solve the problems of harmful gas erosion in goaf, low utilization rate of mining roadway, large deformation of roadway roof, etc., to avoid Harmful gas enters the work area, wide applicability, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

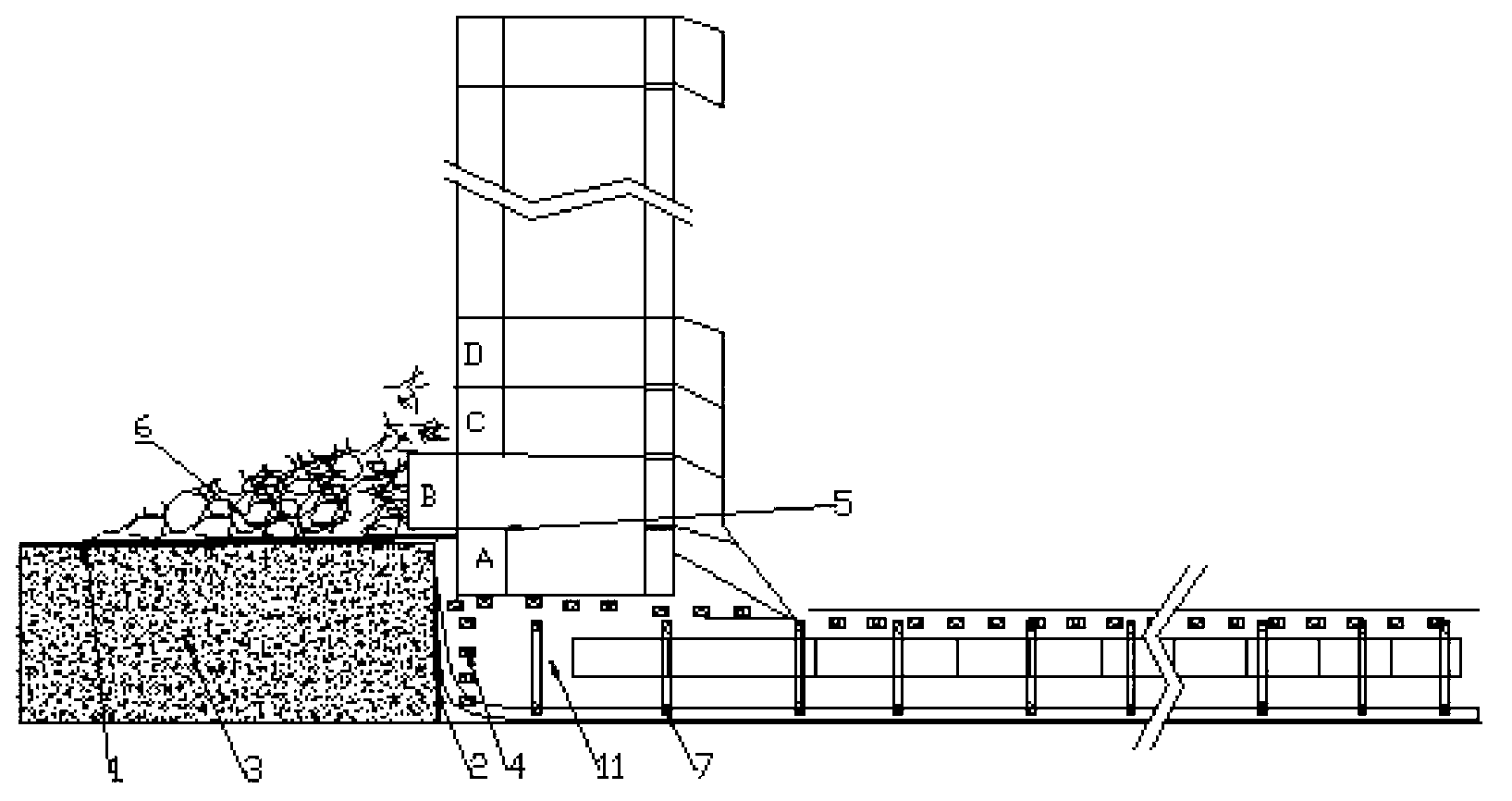

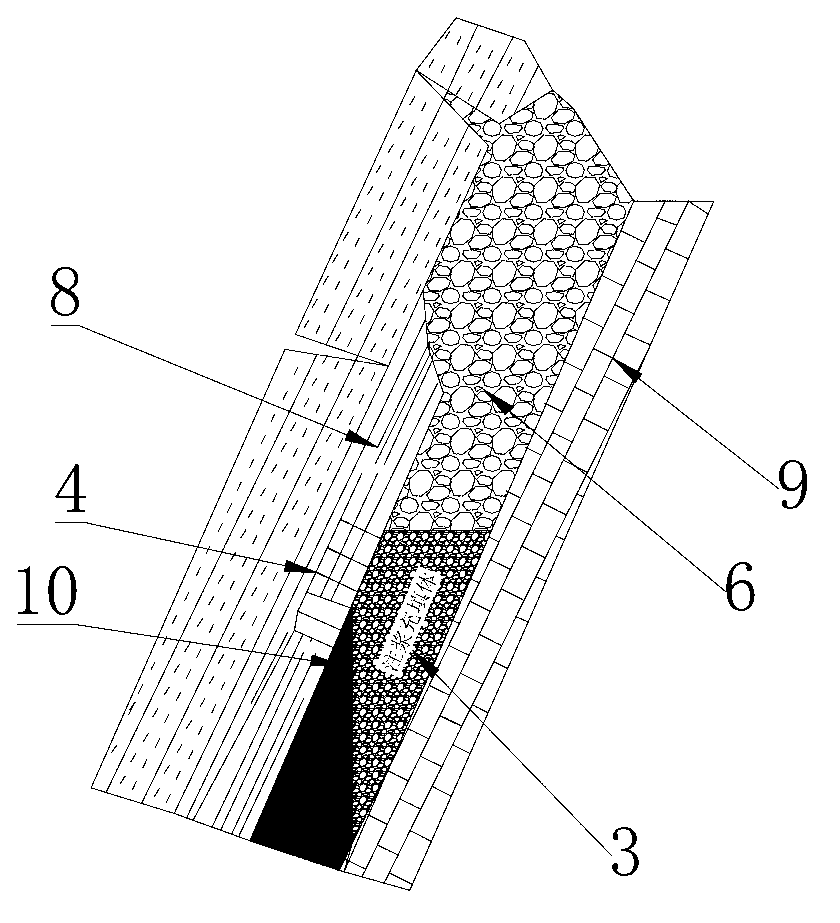

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0017] The filling method next to the coal pillar roadway in the steeply inclined coal seam section of the present invention, the specific steps are as follows:

[0018] 1. First process the filling material on the ground according to the mass ratio of No. 42.5 ordinary Portland cement: sand: crushed stone = 1:2:2, put the mixed filling material into the filling bag and seal it, and use a mine truck Transport it down the well until it is ready for use in the level roadway of the section; during the production of the working face, it is carried out 12 cycles per day, and the footage per cycle is 0.8m, that is, the daily footage of the working face is estimated to be 9.6m, and the daily filling material required is: 9.6 ×10.71=103m 3 , then press 110m per day 3 Material preparation;

[0019] 2. According to the daily footage of the working face, it is esti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap