Flow-cutting channel type water turbine

A channel-type water turbine technology, applied in the field of water turbines, can solve the problems of less series of impact water turbines and low efficiency, and achieve the effect of high cost performance, high efficiency, and easy production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

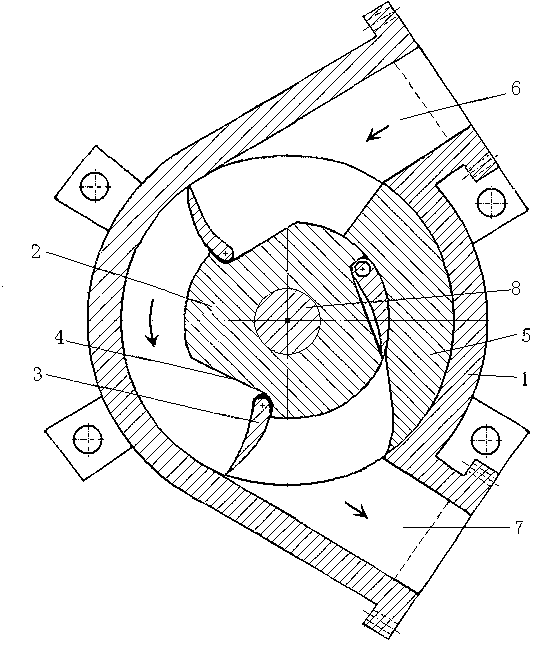

[0026] Such as figure 1 As shown, this embodiment is a single tangential channel turbine, including a casing 1 and a main shaft 8 at the center, a runner 2 located outside the main shaft and rigidly connected to the main shaft, the runner 2 is a cylinder, and the runner 2 Three gate-shaped blades 3 are evenly arranged on the upper part, and a blade chamber 4 for accommodating the blades is also provided on the runner. One end of the blade chamber 4 is provided with a limit part for limiting the expansion angle of the blades. The blade chamber is used for accommodating and restricting the blades. Expanded angle, the casing 1 is also provided with a partition 5 for guiding the blades to enter the blade chamber; the partition 5 blocks the right water flow channel of the two water flow channels in the turbine casing, leaving the left The water flow channel (or the left water flow channel is blocked, the right water flow channel is reserved). The water flow channel is provided with a...

Embodiment 2

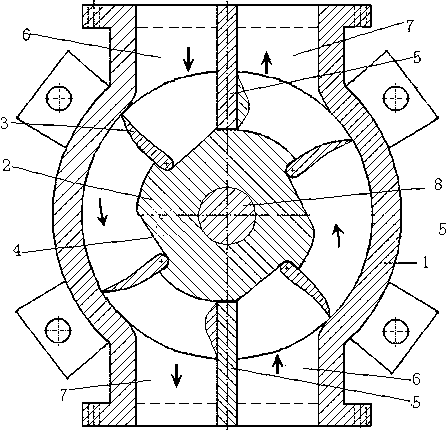

[0032] Such as figure 2 As shown, this embodiment is a double tangential channel hydraulic turbine, which includes a casing 1 and a main shaft 8 in the center. The runner 2 is located outside the main shaft and is rigidly connected to the main shaft. The runner 2 is evenly provided with four For the unfolded or retracted blades 3, the runner is also provided with a blade chamber 4 for accommodating the blades when the blades are folded. One end of the blade chamber 4 is provided with a limit part for limiting the unfolding angle of the blades. There are also two inside the casing 1. The partition body 5 used to guide the blades to gather into the blade chamber; the partition body divides the annular water flow channel into two left and right tangential flow channels evenly. The upper end of the left channel is set as a high-pressure water inlet and the lower end is set as a low-pressure water outlet. , The direction of water flow in the left channel is counterclockwise; the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com