Patents

Literature

36results about How to "Low installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

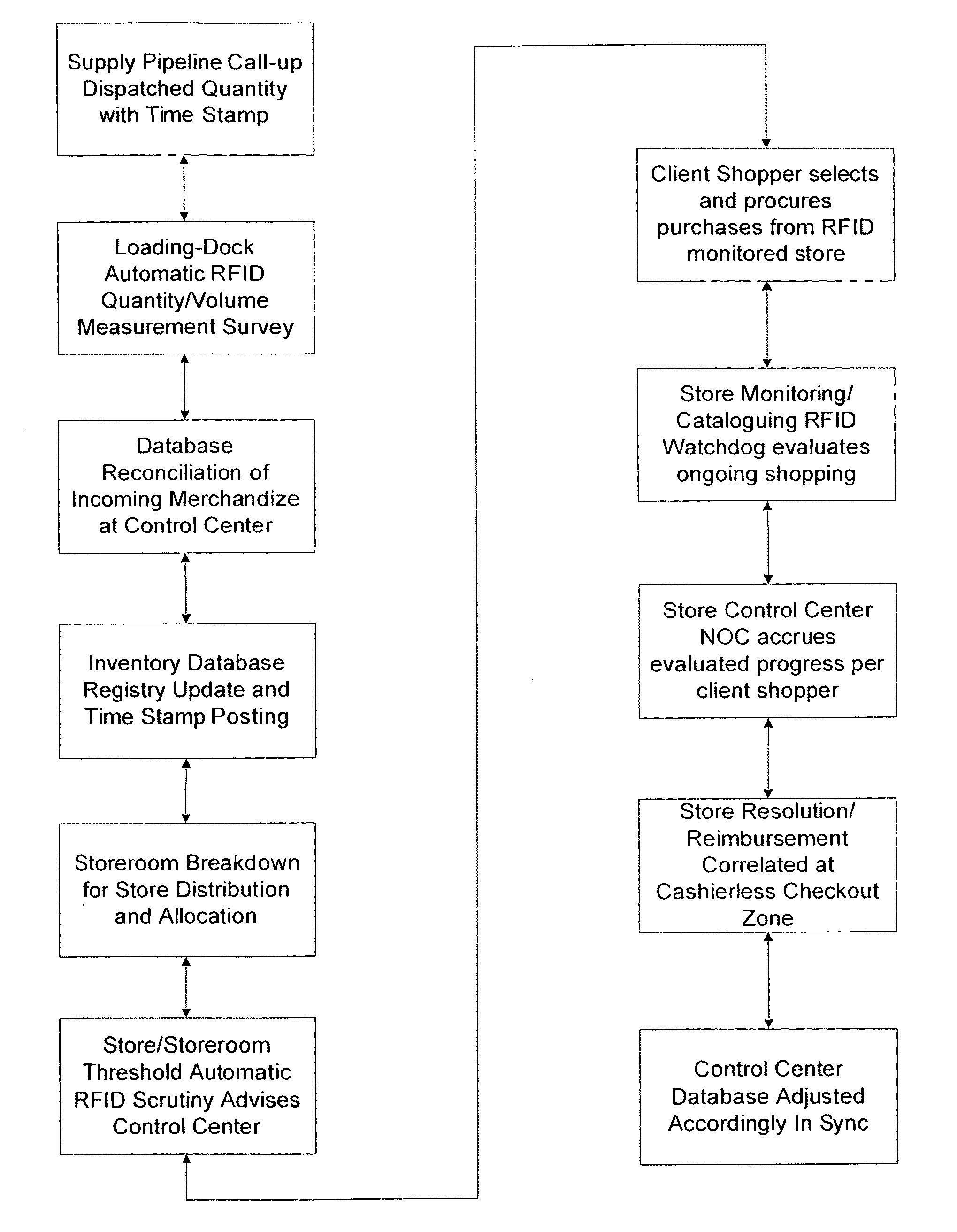

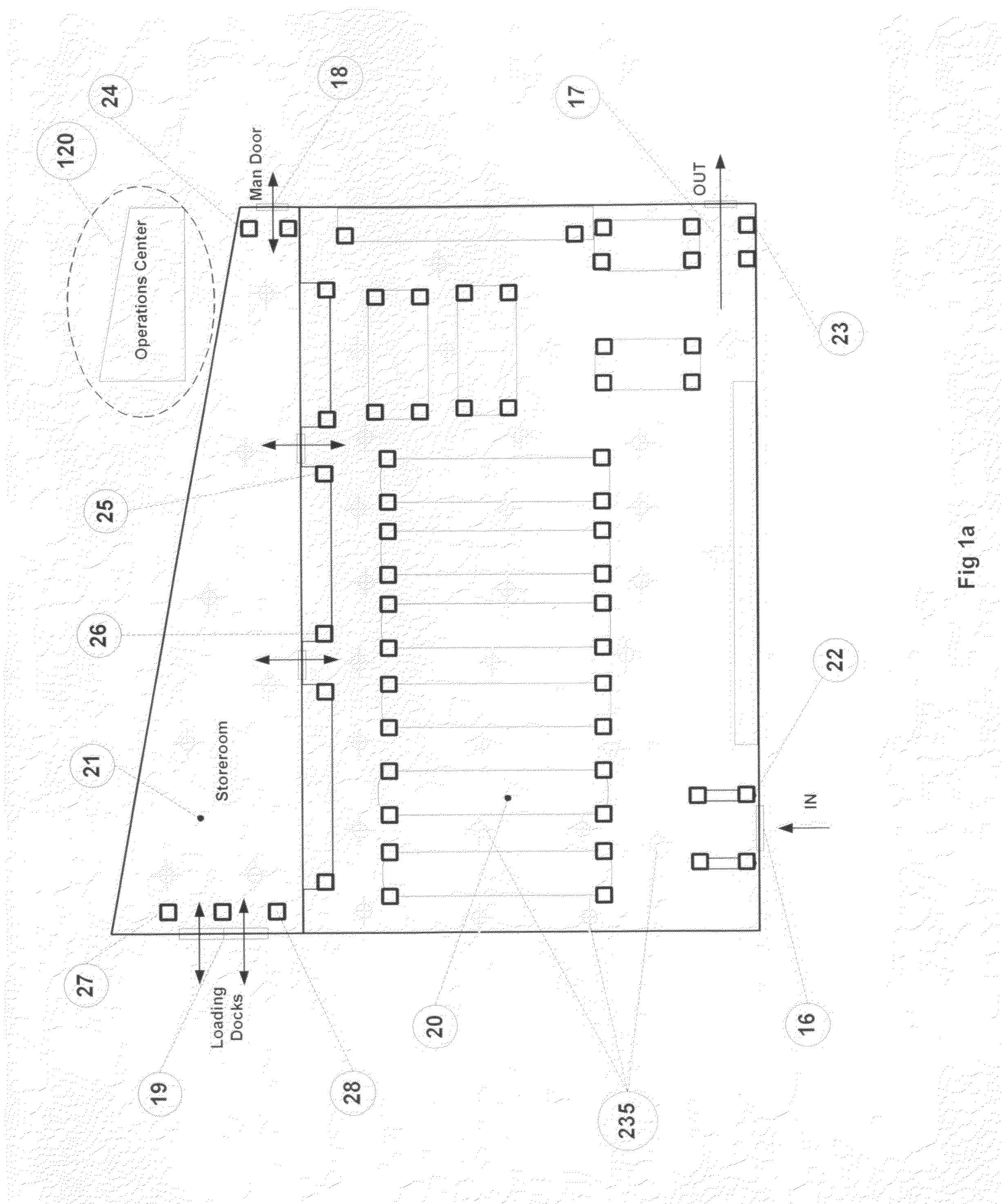

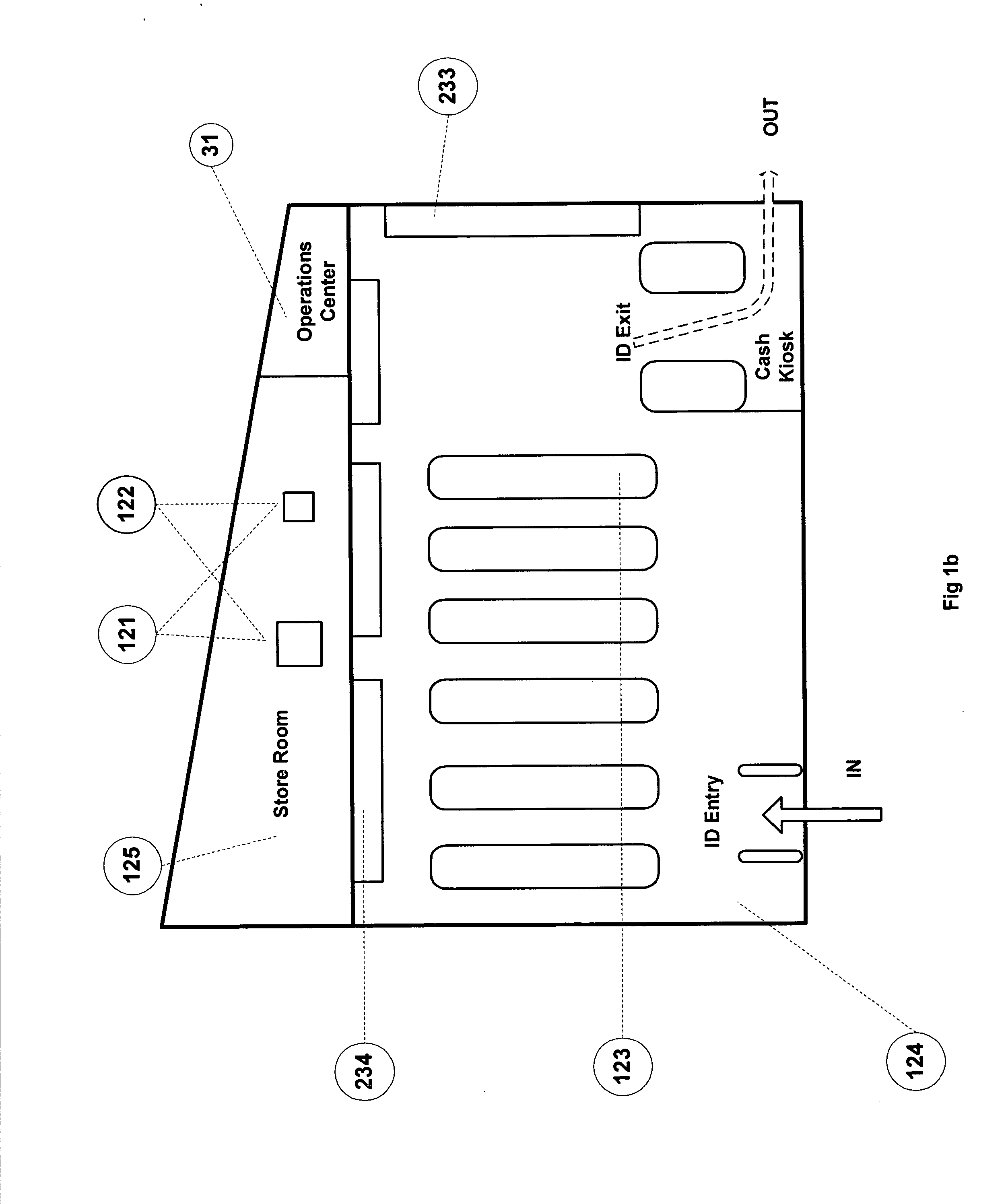

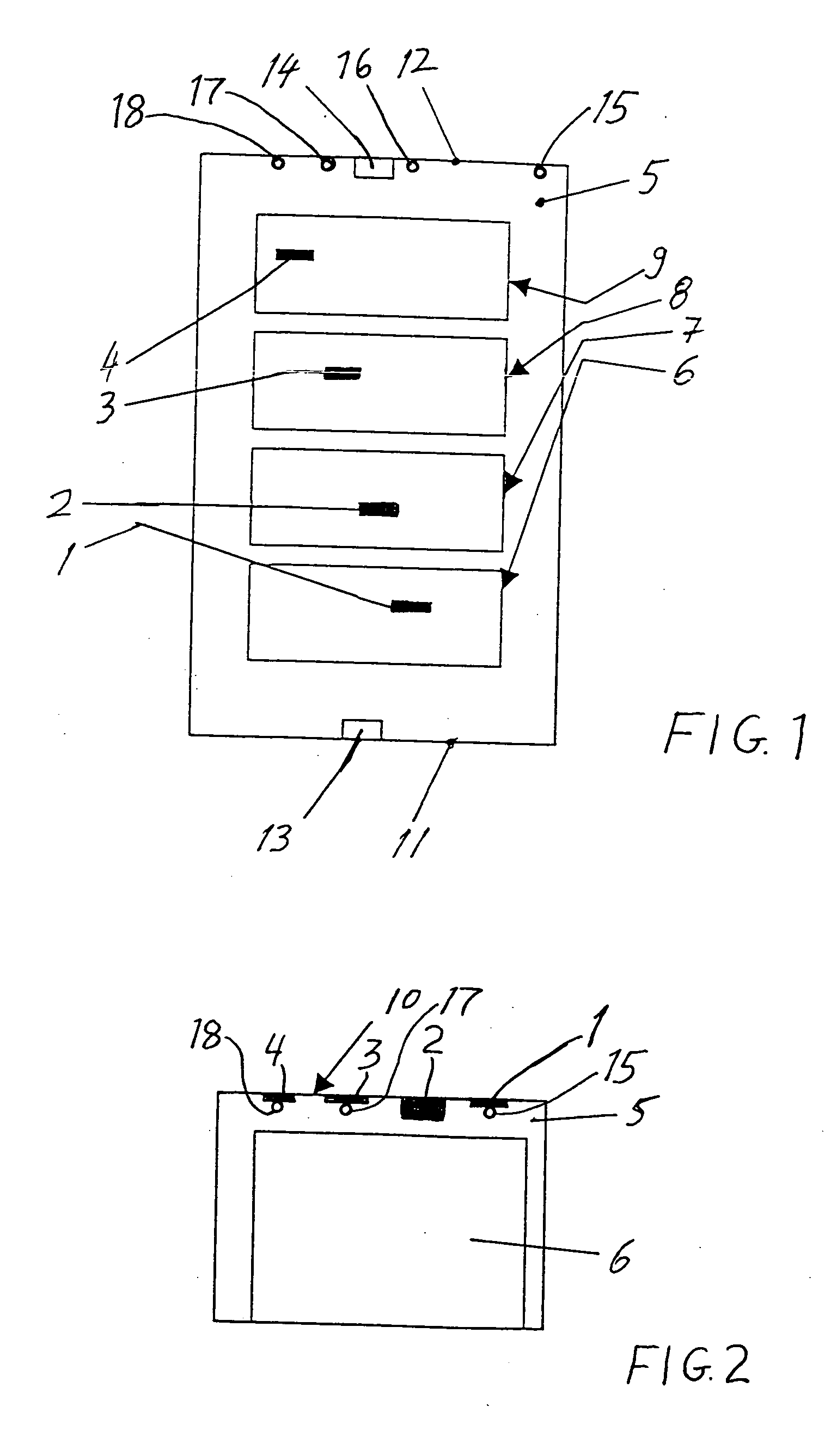

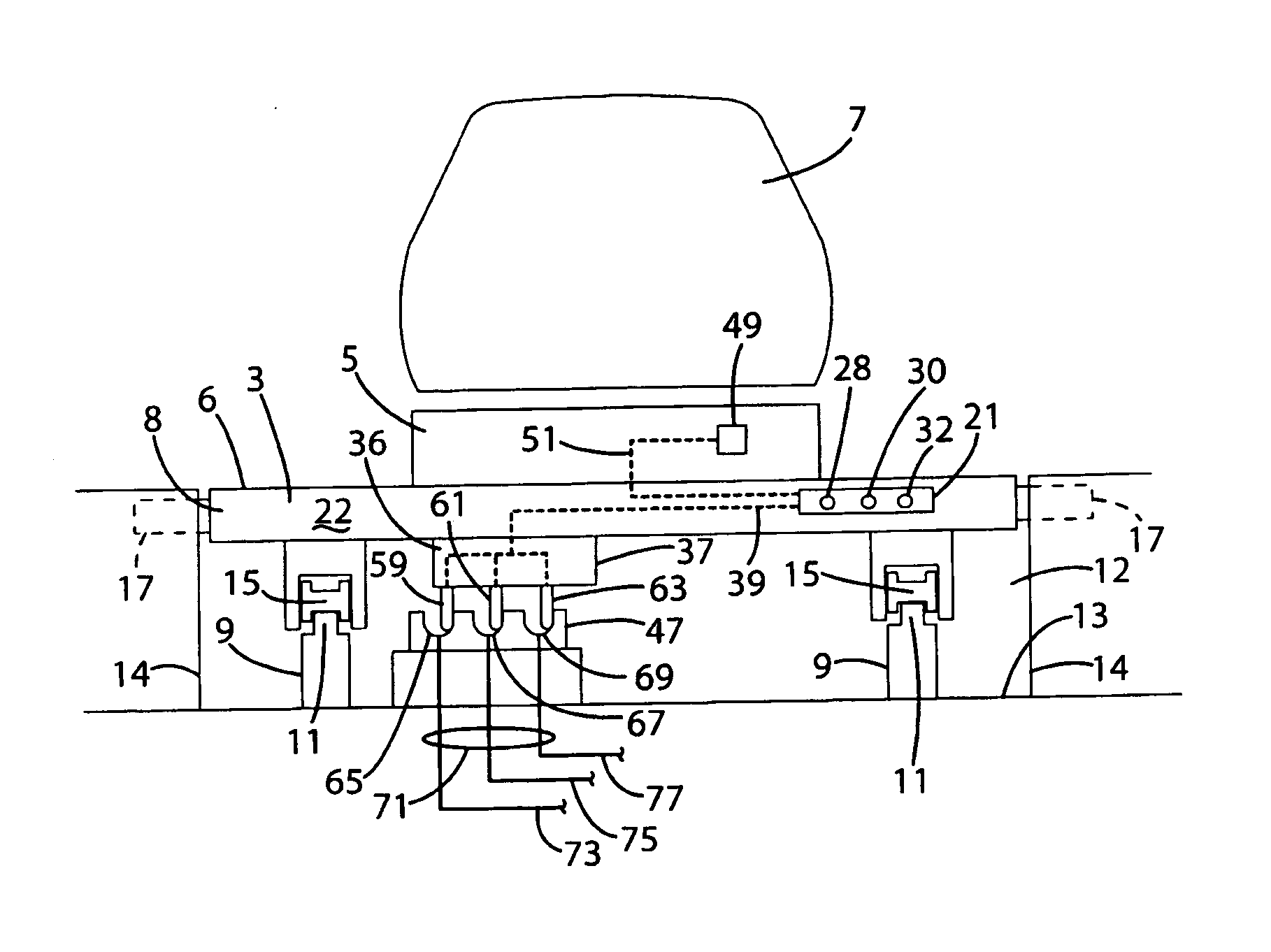

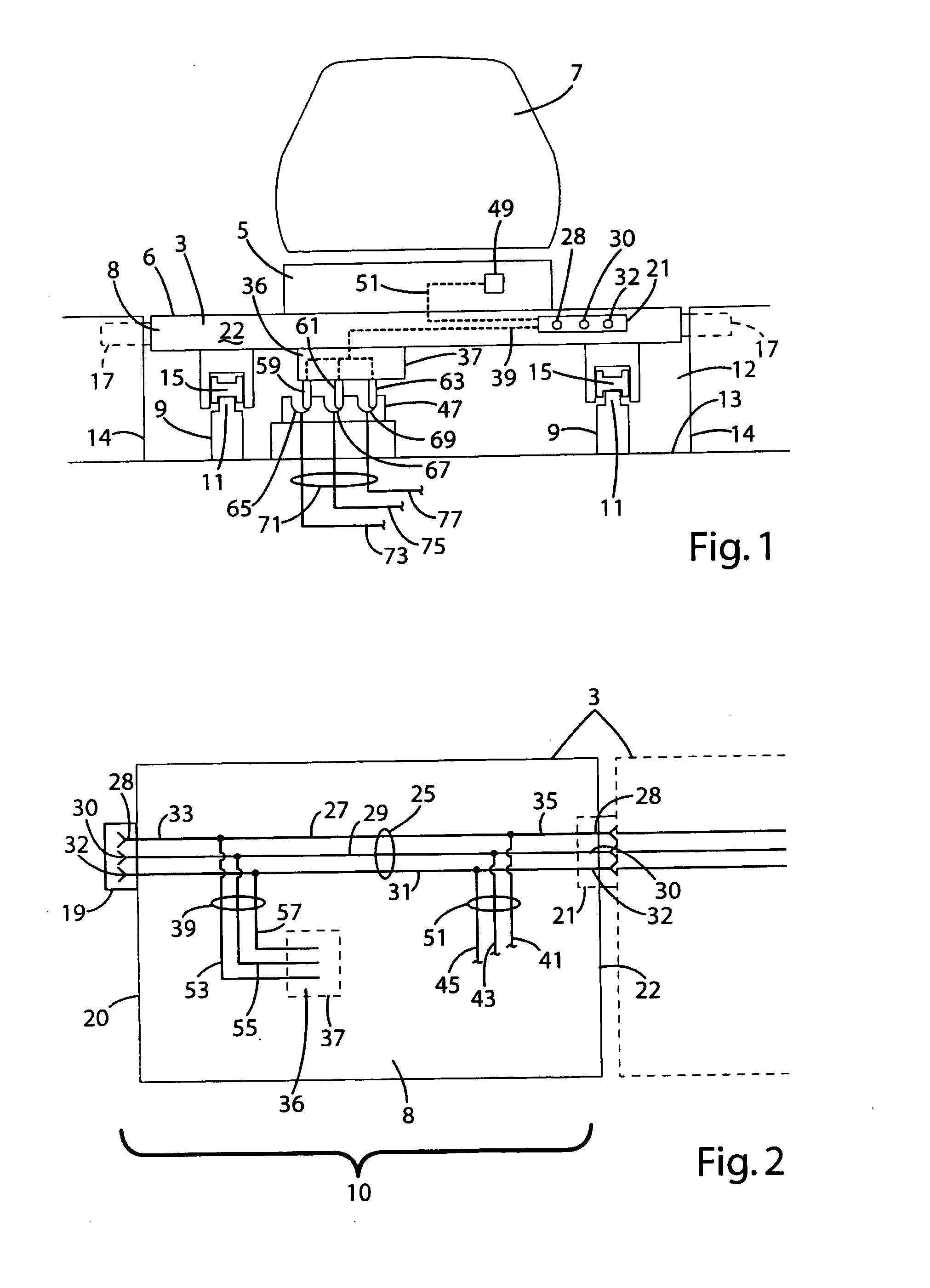

Cashierless, Hygienic, Automated, Computerized, Programmed Shopping Store, Storeroom And Supply Pipeline With Administration Cataloguing To Eliminate Retail Fraud; With Innovative Components For Use Therein

InactiveUS20100318440A1Cost expenditure increaseInstallation cost-effectivenessElectric signal transmission systemsDigital data processing detailsSensor arrayTelecommunications link

A Cashierless unattended point of sale, shopping store procurement payment means, with storeroom reordering system using a layered wireless linked monitoring and cataloguing system; includes an interfacing electronic configured self-owned reusable three-wheel fold-up shopping trolley with suspended color-coded bins; into which merchandise maybe placed and registered by a passive reading sensor array. A ‘load-cell’ integral to the trolley precisely quantifies and approves trolley bin contents for exit payment through a TCP / IP means. An evaluation wireless communication link repeatedly reviews “polled' trolley content data, this integrated communication link, is networked to the store Operations Center, wherein purchased inventory data is recorded and verified; upon shopping completion the contents are again finally substantiated for final electronic settlement. This self-contained cashierless enclosed shopping method provides retail loss prevention, real-time progressive inventory management and reorder, eliminates space to sales; being convenient for shoppers and store owners; making all egress points electronically restricted.

Owner:COVELEY MICHAEL EJ

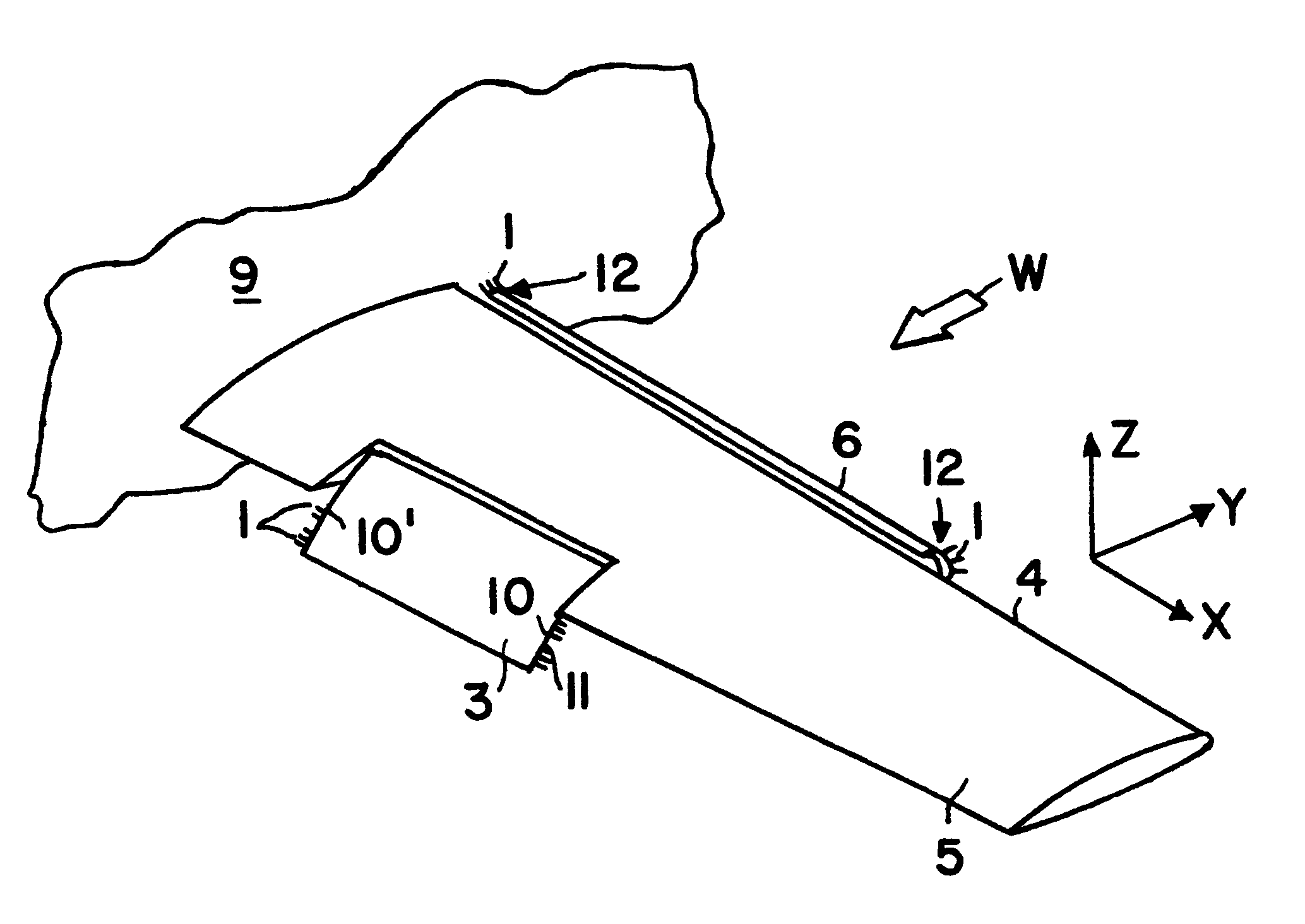

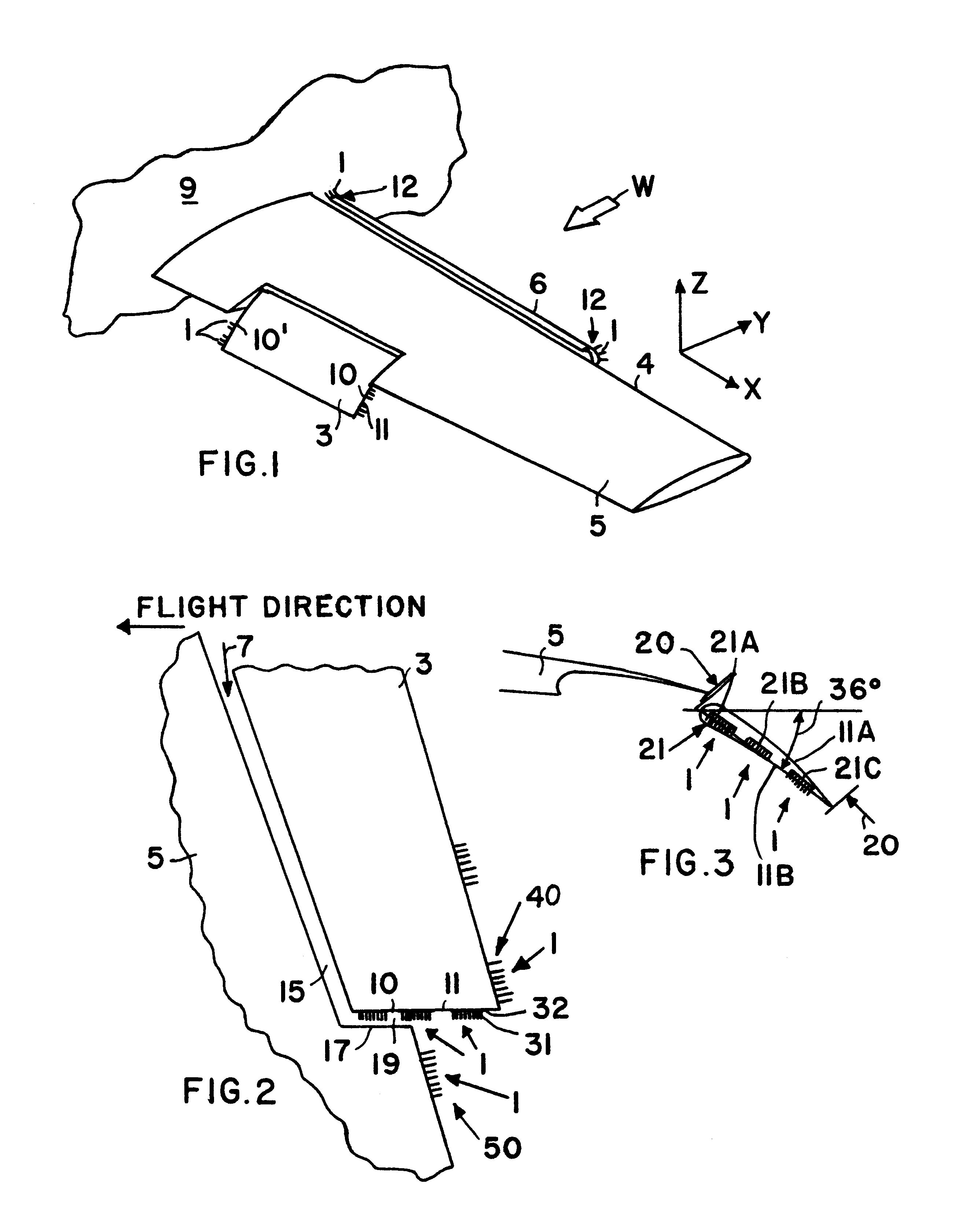

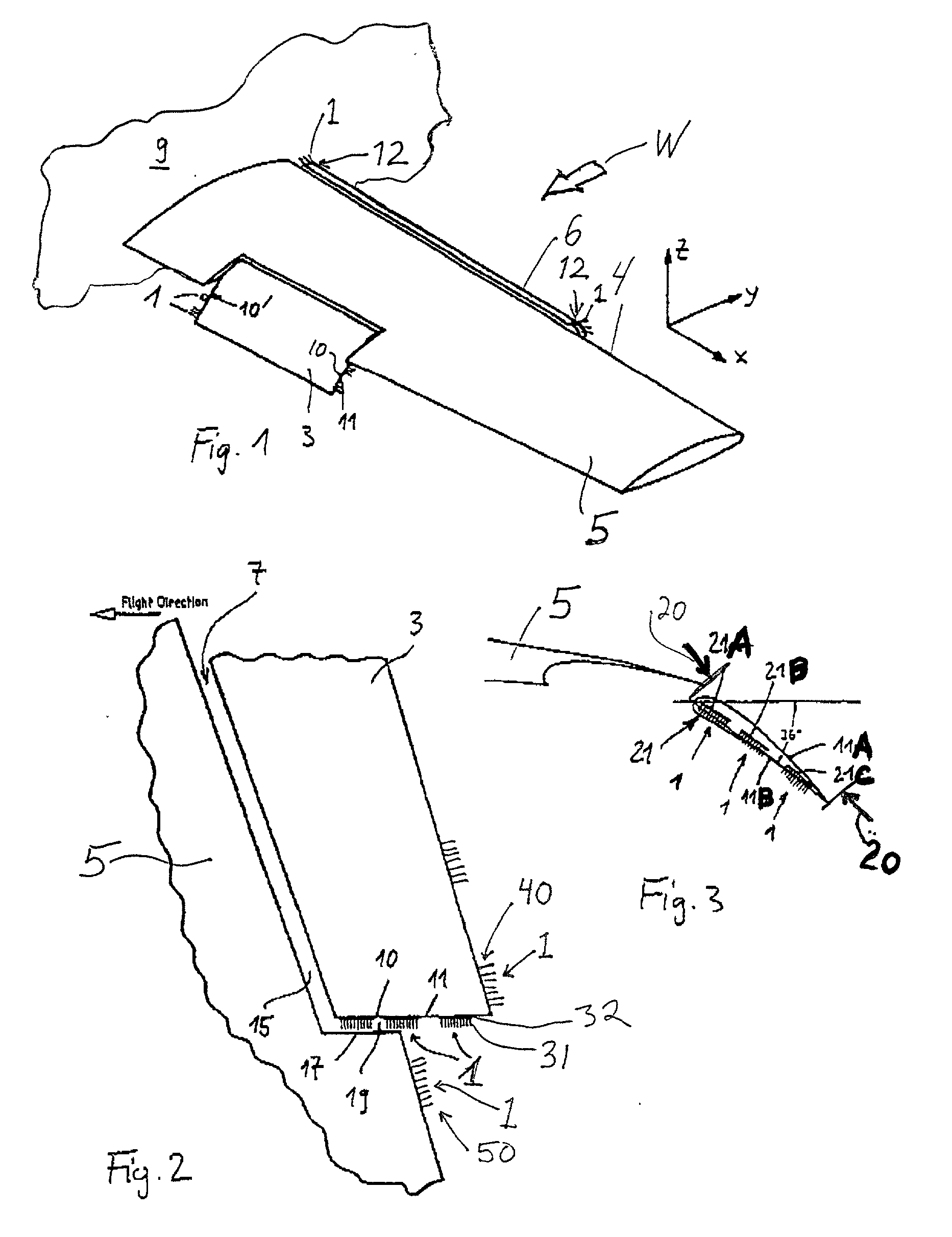

Noise reducing vortex generators on aircraft wing control surfaces

InactiveUS6491260B2Eliminate the effects ofReduced strengthInfluencers by generating vorticesWingsBristleHigh lift

Owner:AIRBUS OPERATIONS GMBH

Noise reducing vortex generators on aircraft wing control surfaces

InactiveUS20010032907A1Eliminate the effects ofReduced strengthInfluencers by generating vorticesAircraft stabilisationBristleHigh lift

Vortex generators are arranged on the edges of aircraft wing control surfaces to generate smaller vortices that weaken the main vortex that would otherwise be generated at these areas, and thereby reduce the aerodynamic generation of noise. Each vortex generator includes plural elongated elements in the form of rigid rods or flexible bristles protruding laterally outwardly from the respective edge of the control surface. The vortex generators are preferably arranged on the inboard and outboard edges of high lift flaps and slats.

Owner:AIRBUS OPERATIONS GMBH

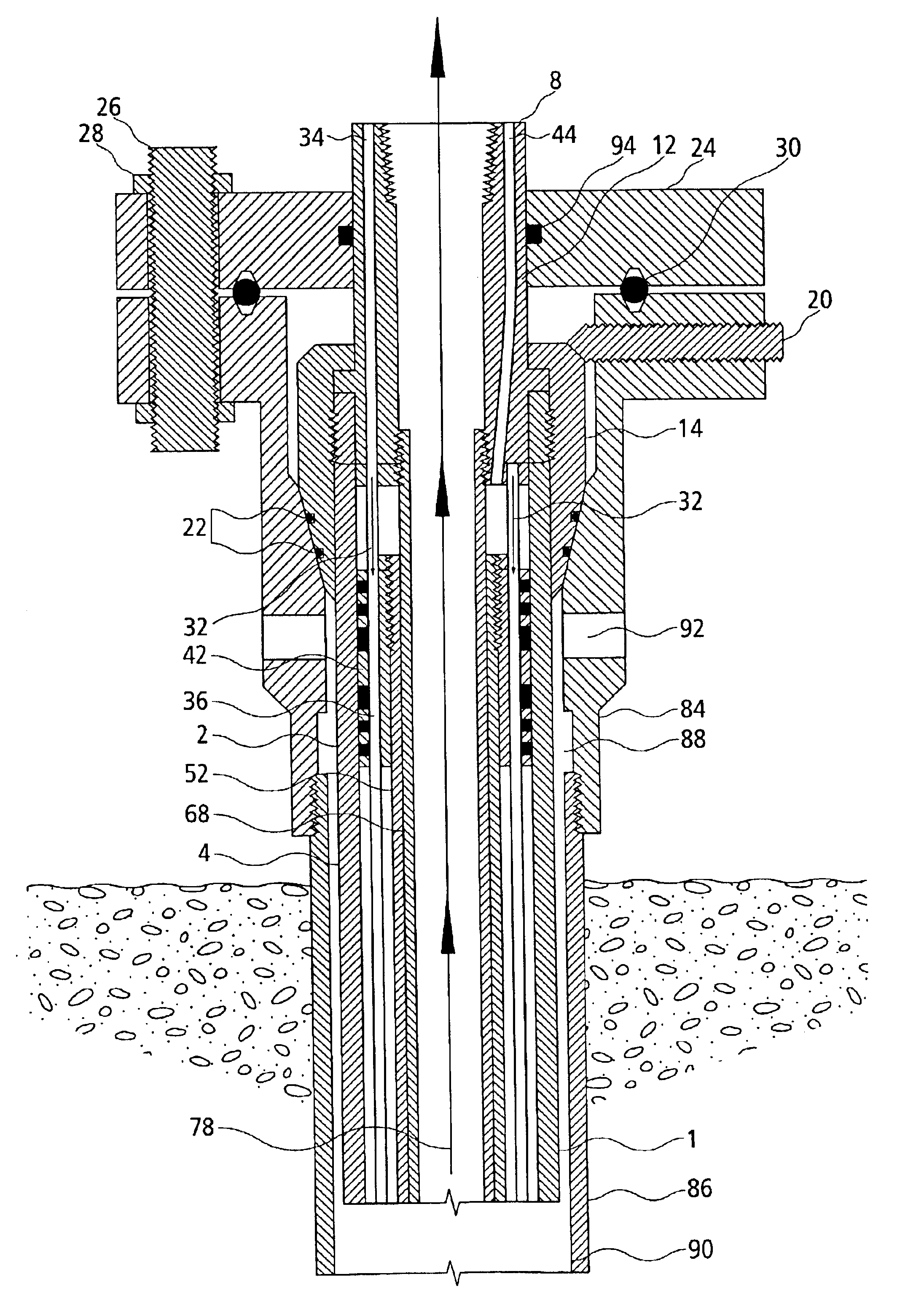

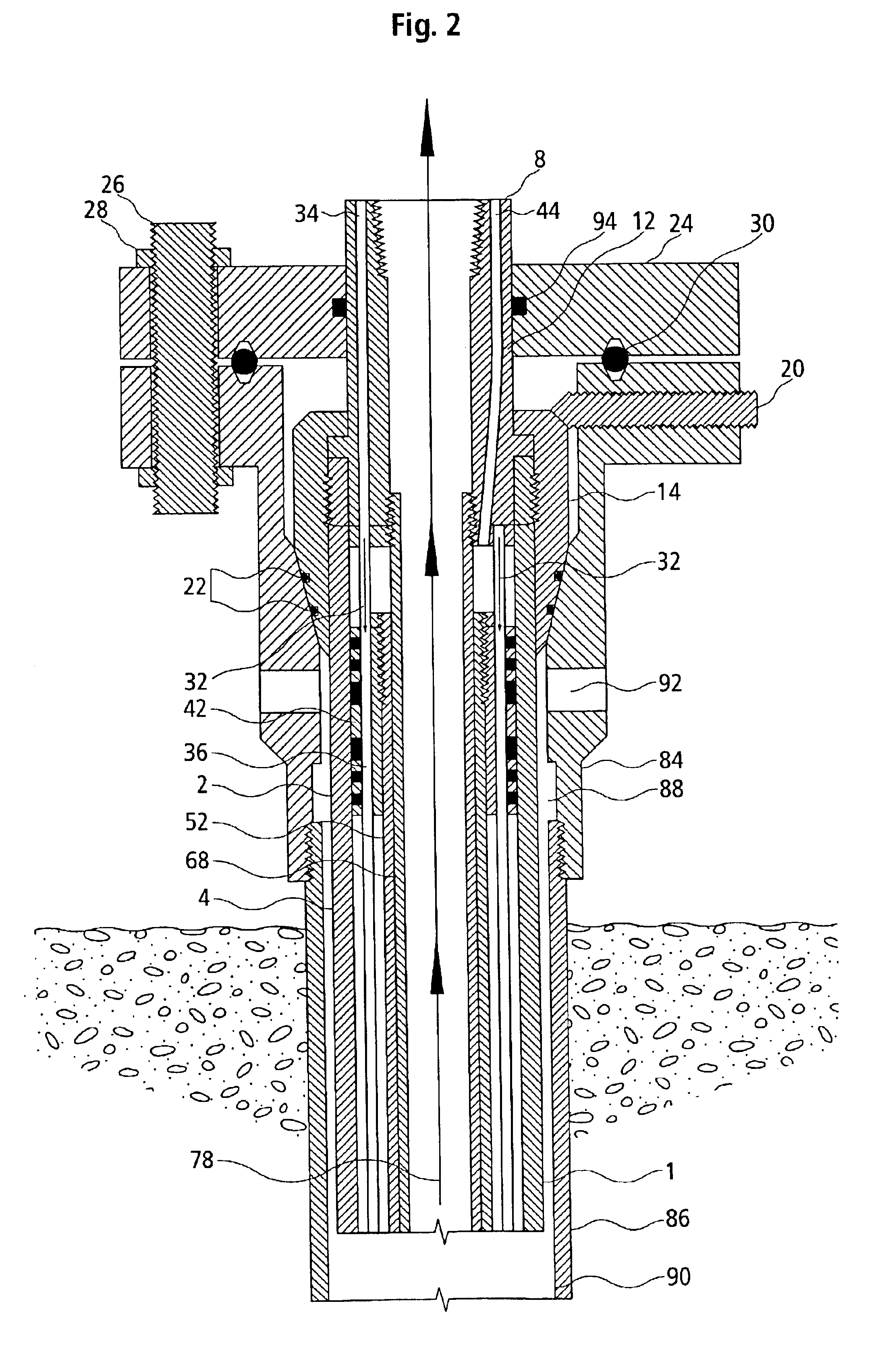

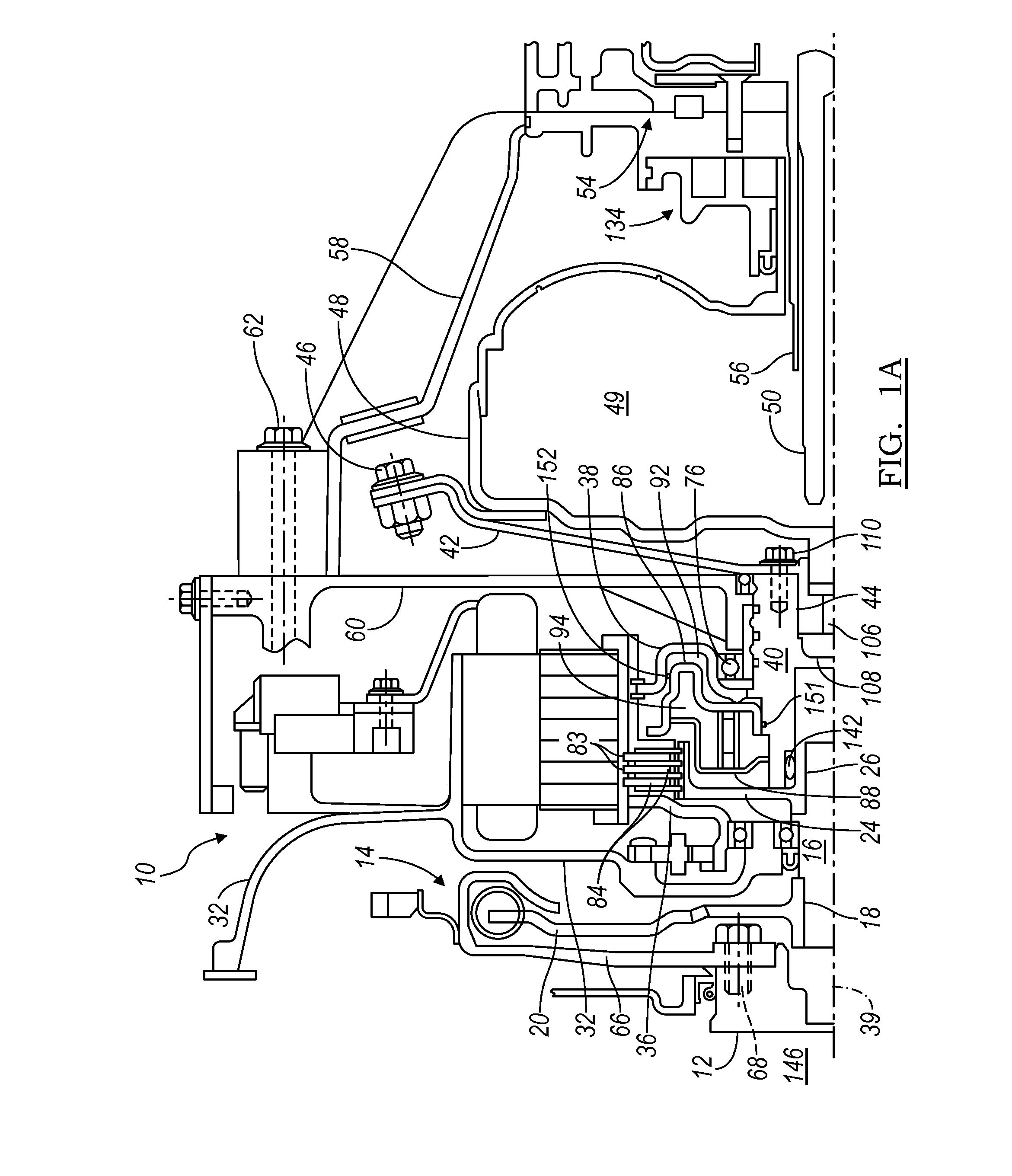

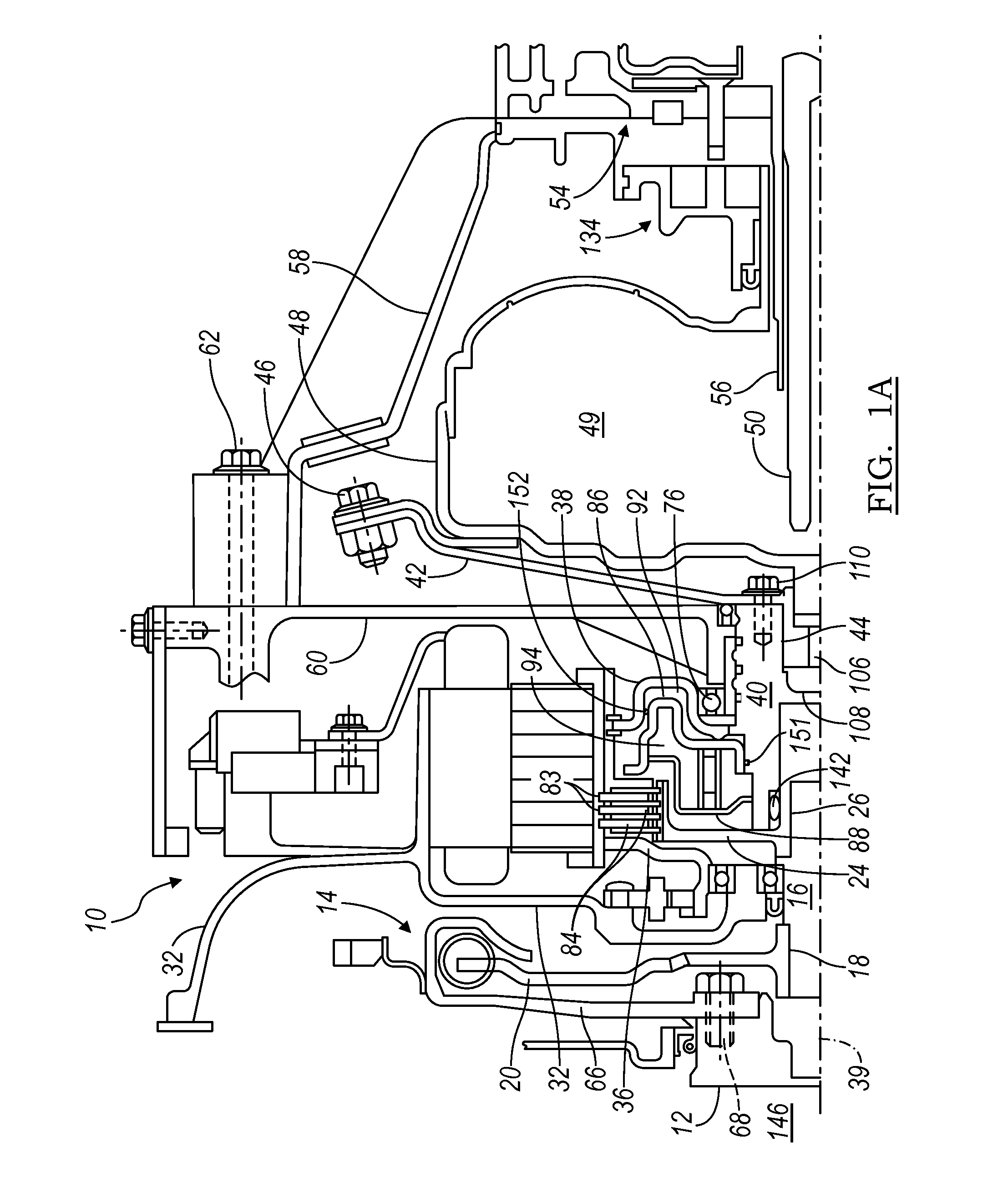

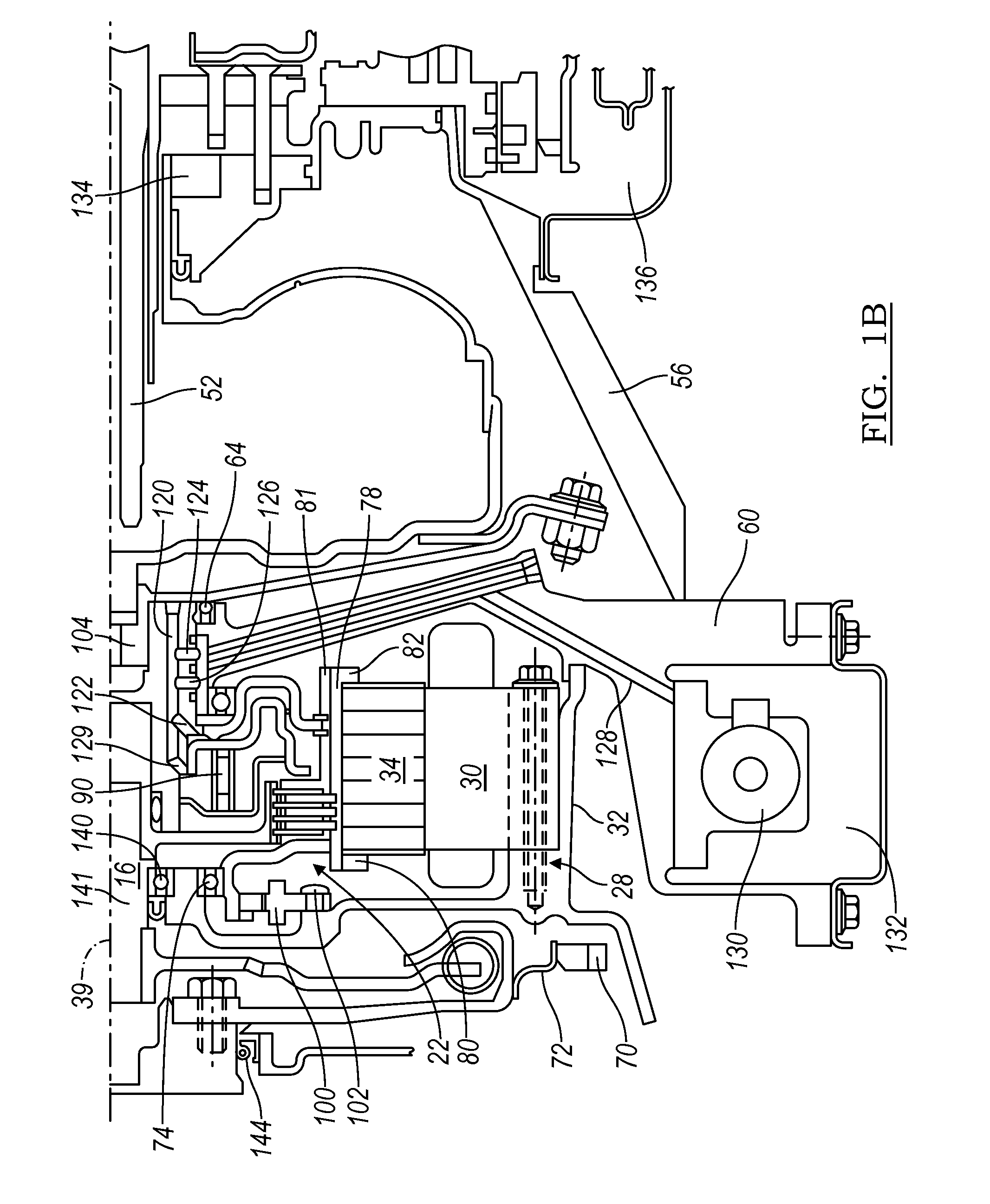

Wellhead hydraulic drive unit

InactiveUS6854515B2Eliminate needEliminate alignment issuesDrilling rodsFlexible member pumpsHydraulic cylinderEngineering

The present invention provides a wellhead hydraulic drive unit to operate various styles of downhole pumps, which is installed as an integral part of a wellhead thereby eliminating the need for a stuffing box. The wellhead hydraulic drive unit comprises a hollow hydraulic cylinder having a piston positioned therein, a hydraulic fluid supply attached to the hydraulic cylinder for raising the piston within the hydraulic cylinder, a hollow ram slideably received within the inner wall of the hydraulic cylinder and connected to the piston for reciprocation in response to the piston; and a production tube inserted through the ram for enabling well fluid to be discharged from the well.

Owner:INNOVATIVE PRODN TECH

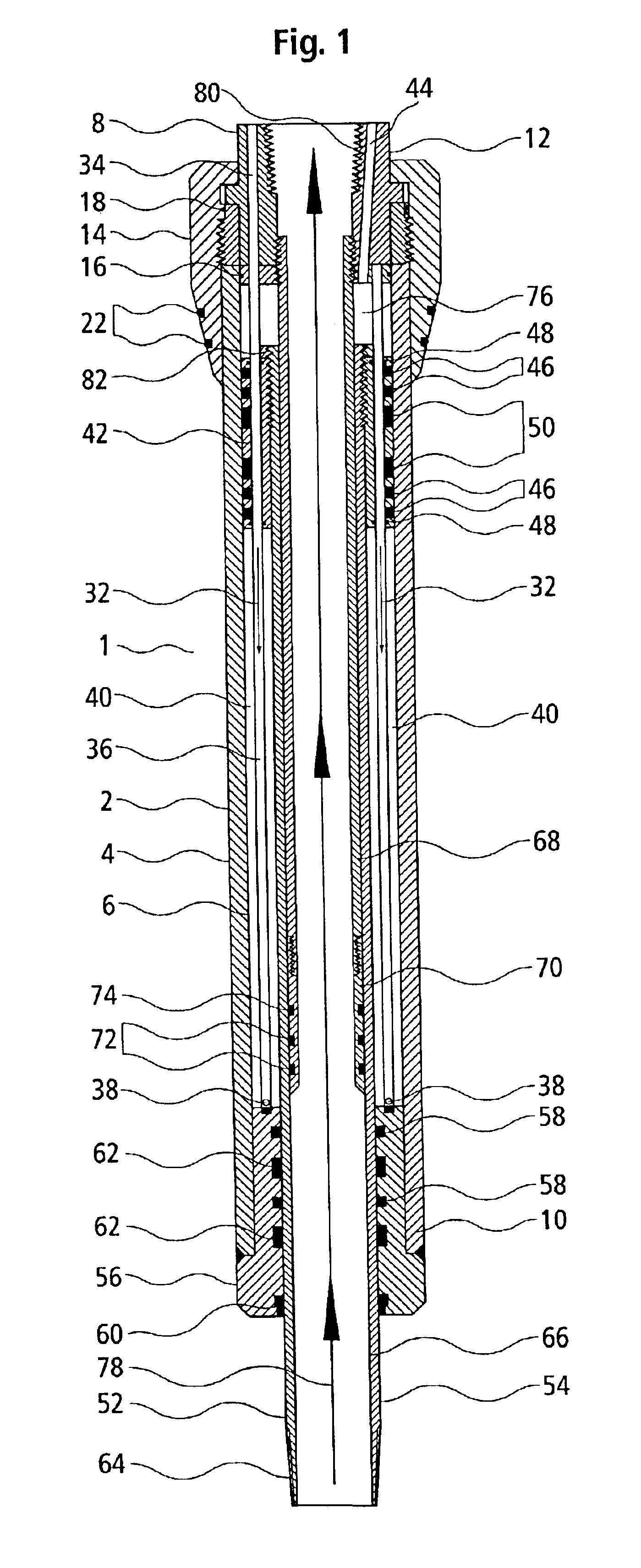

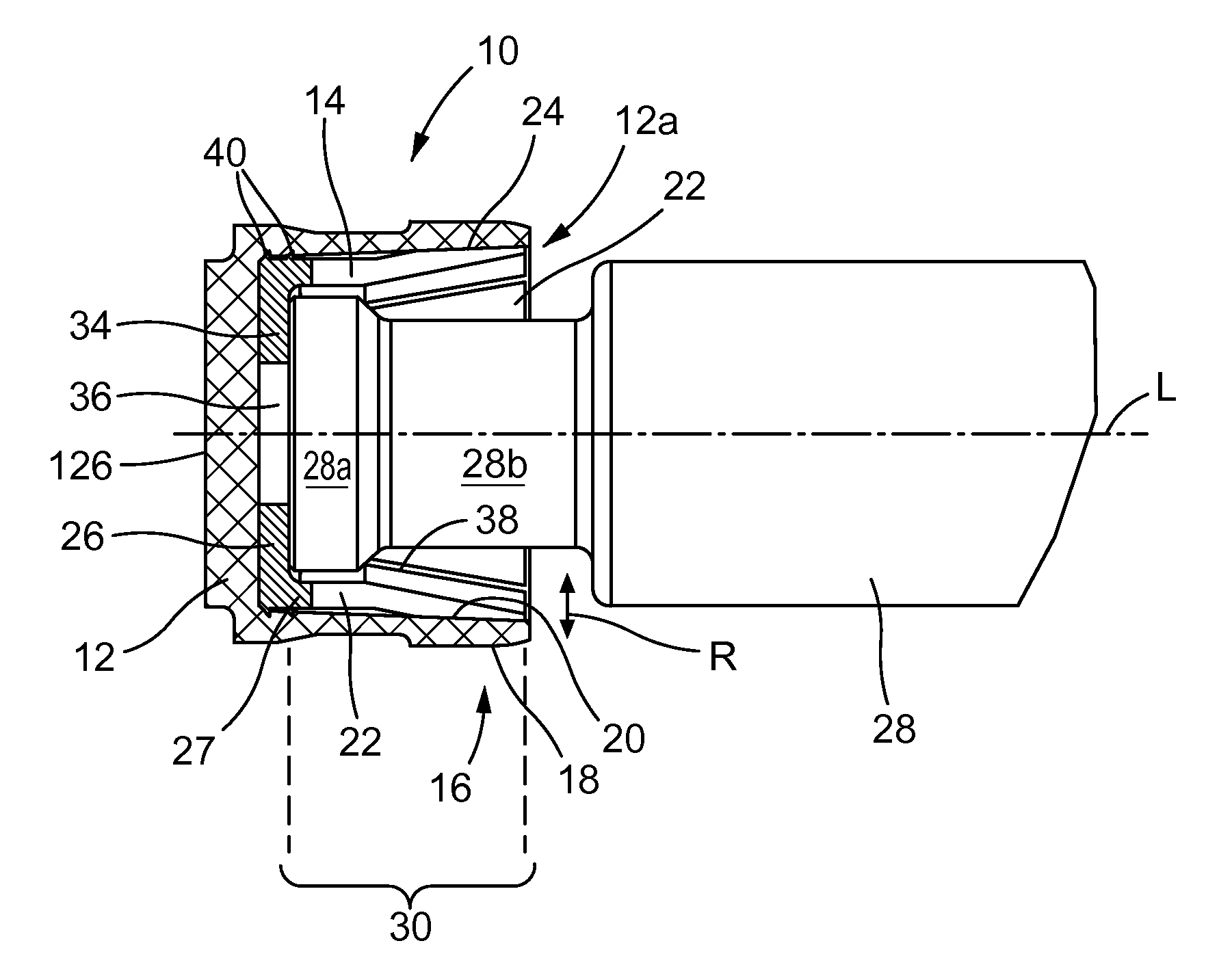

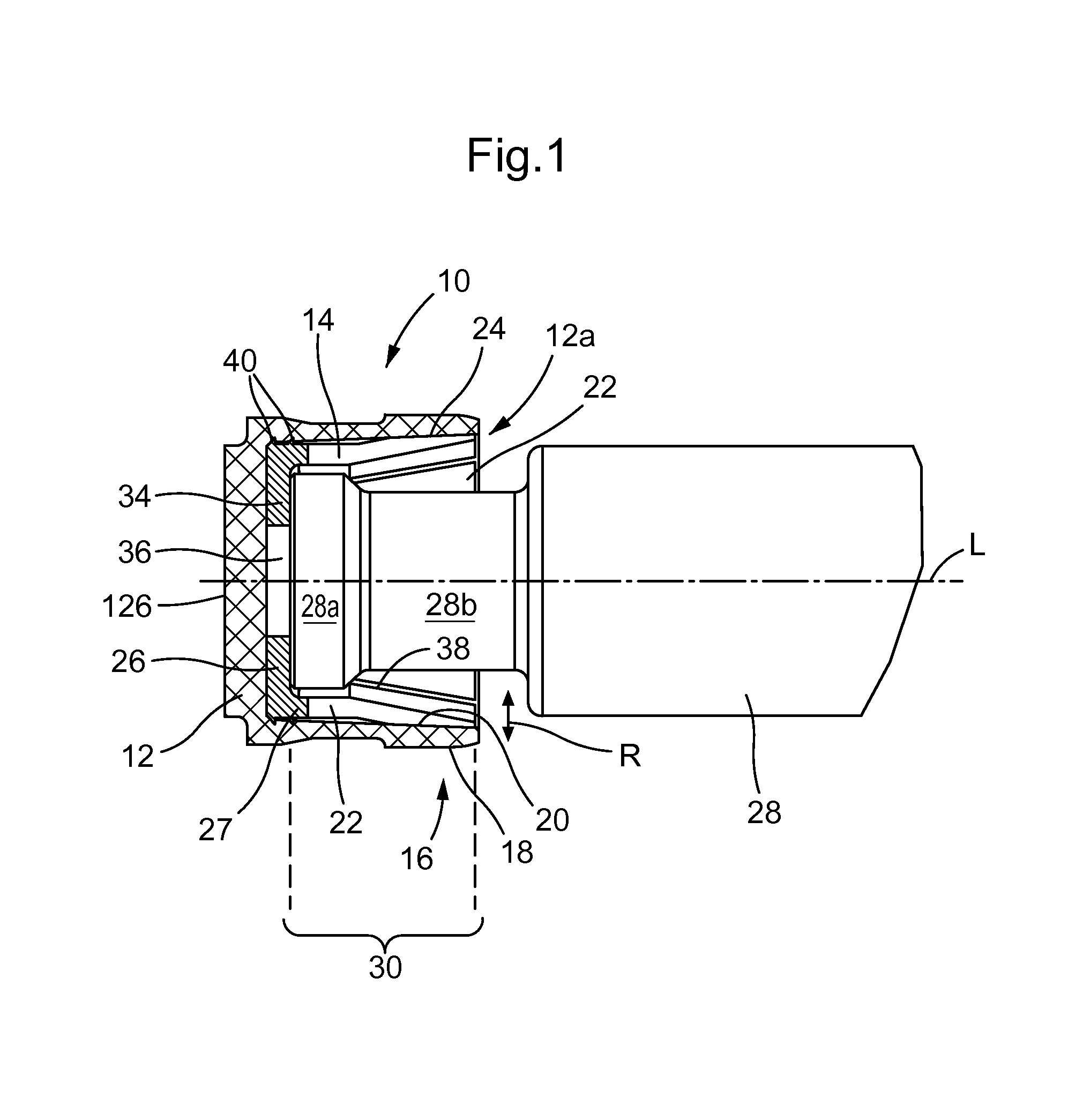

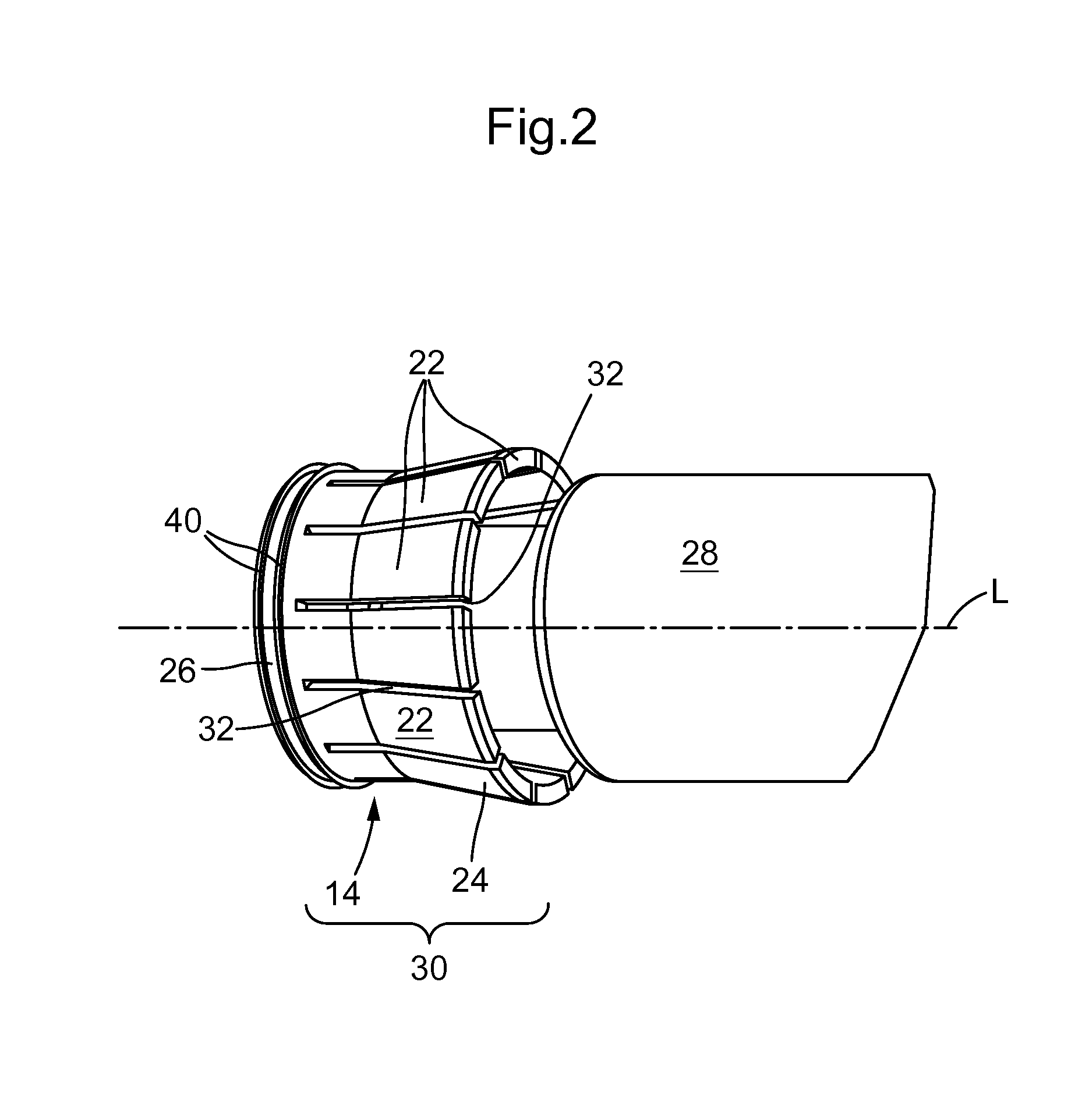

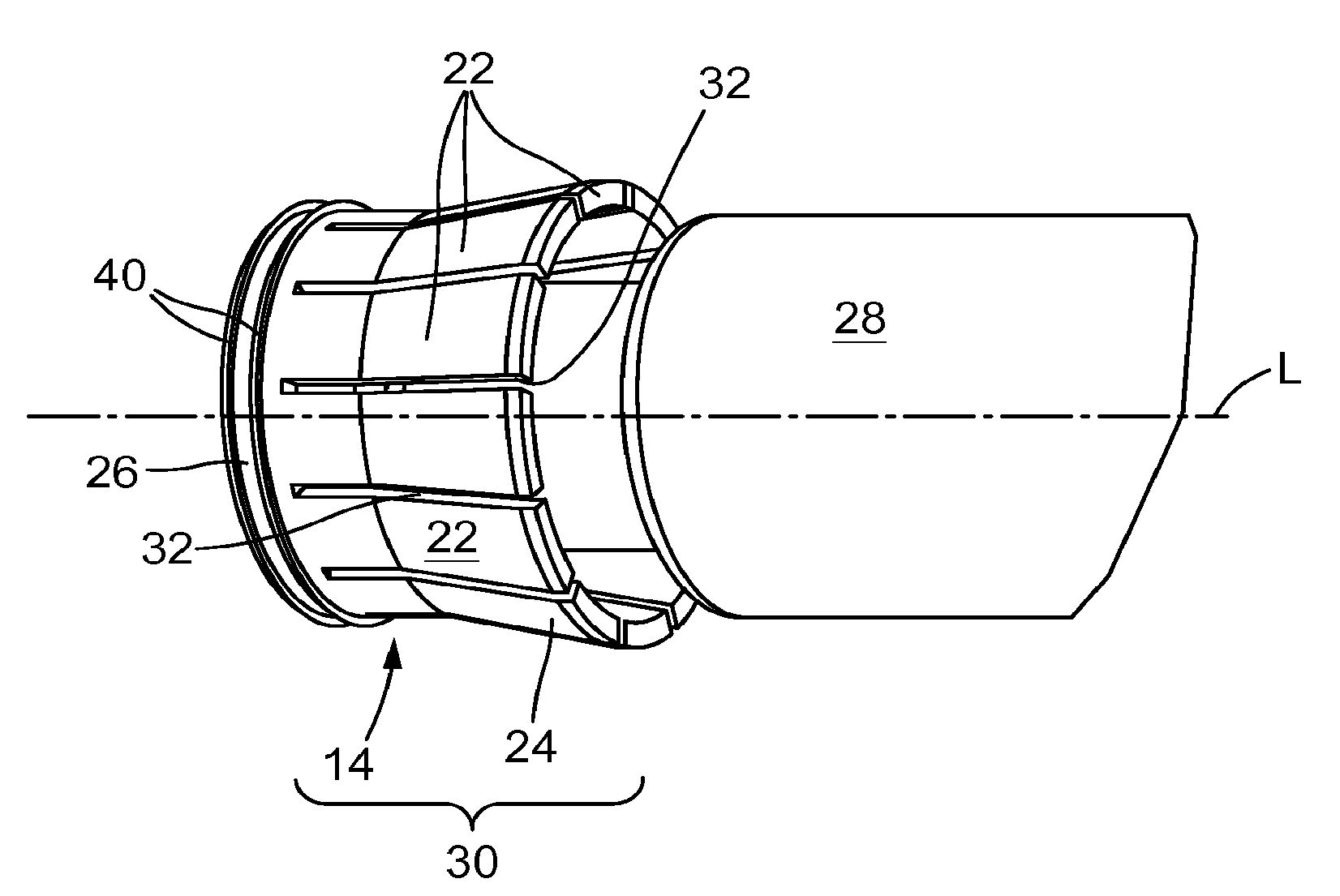

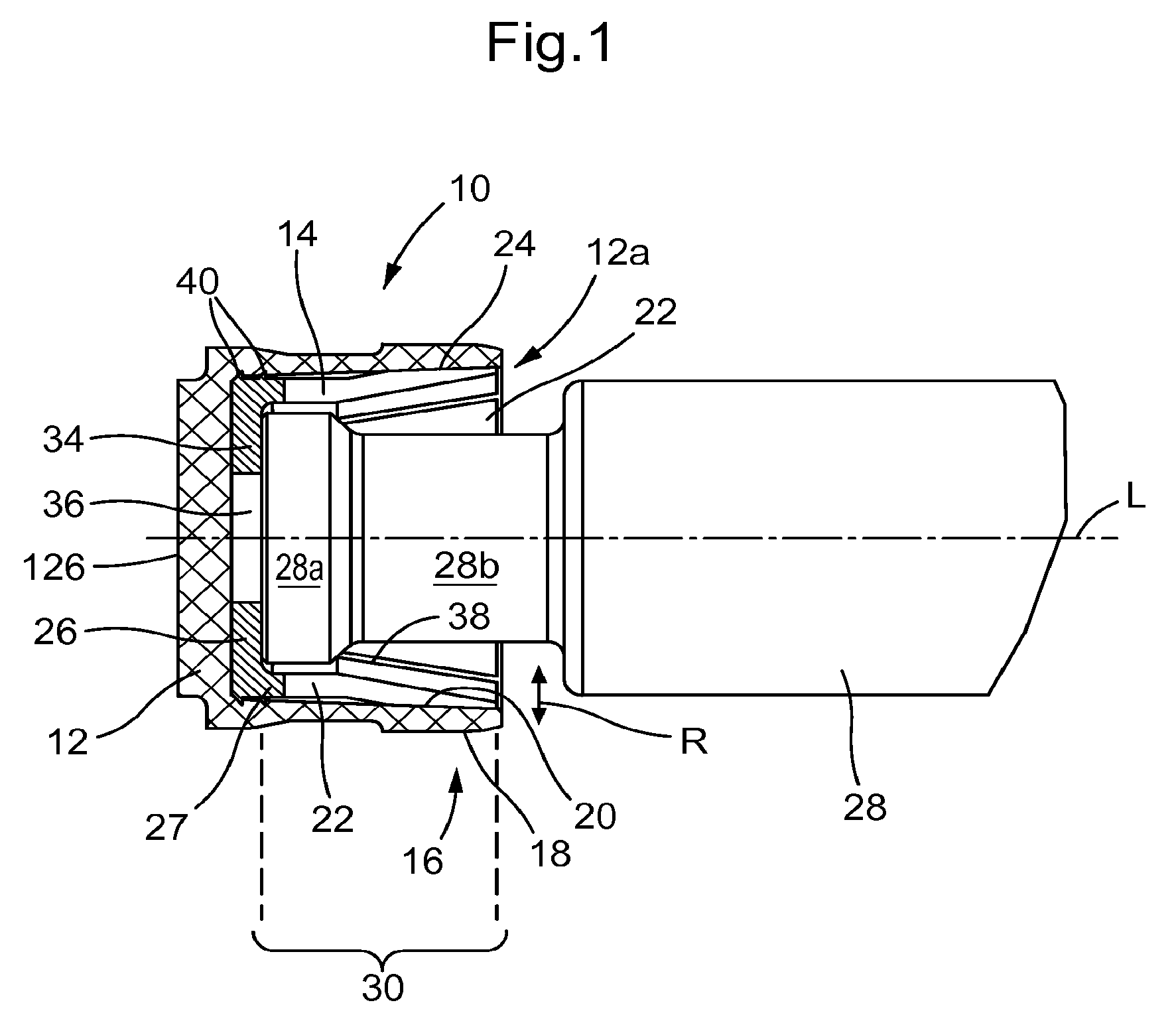

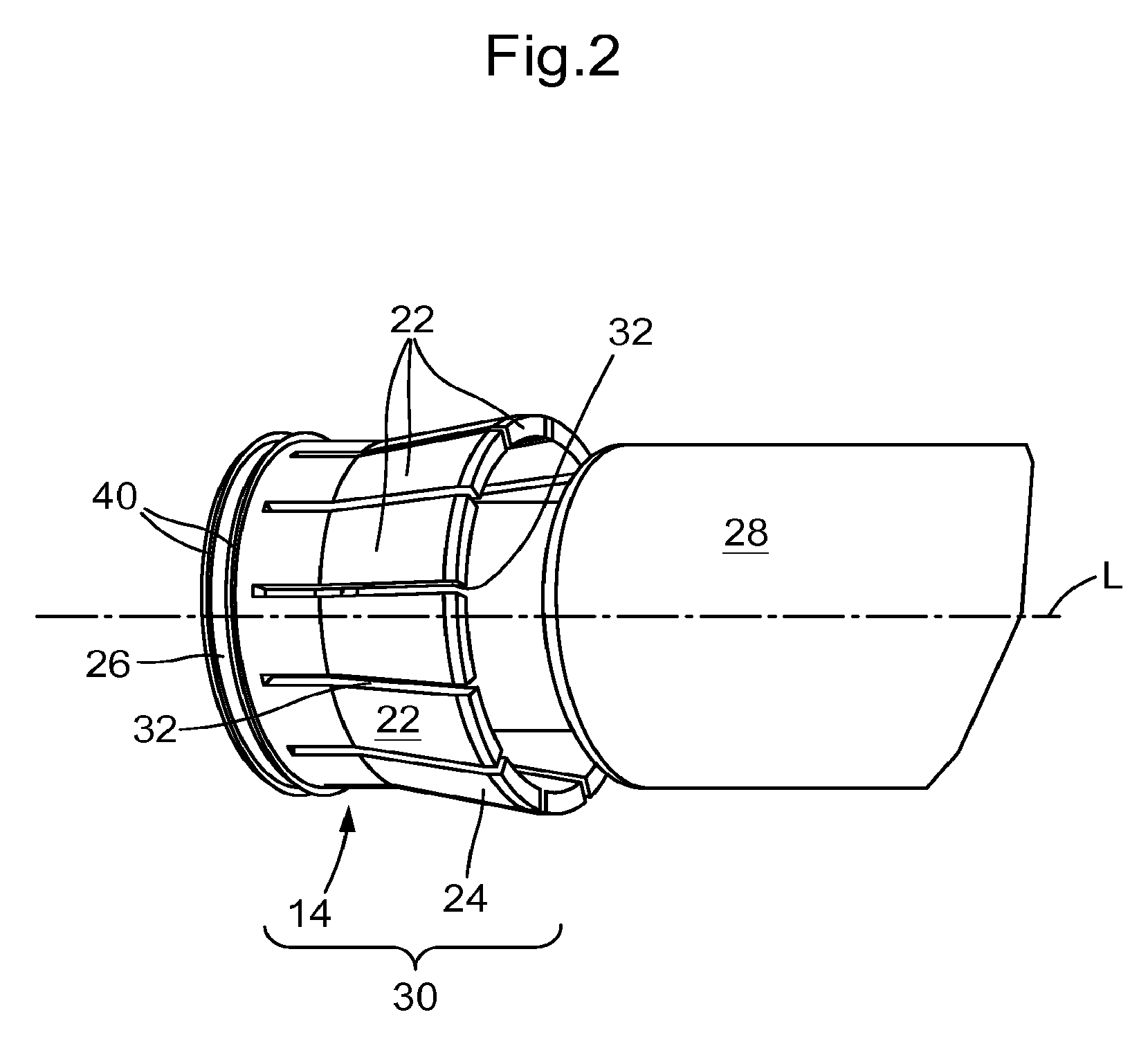

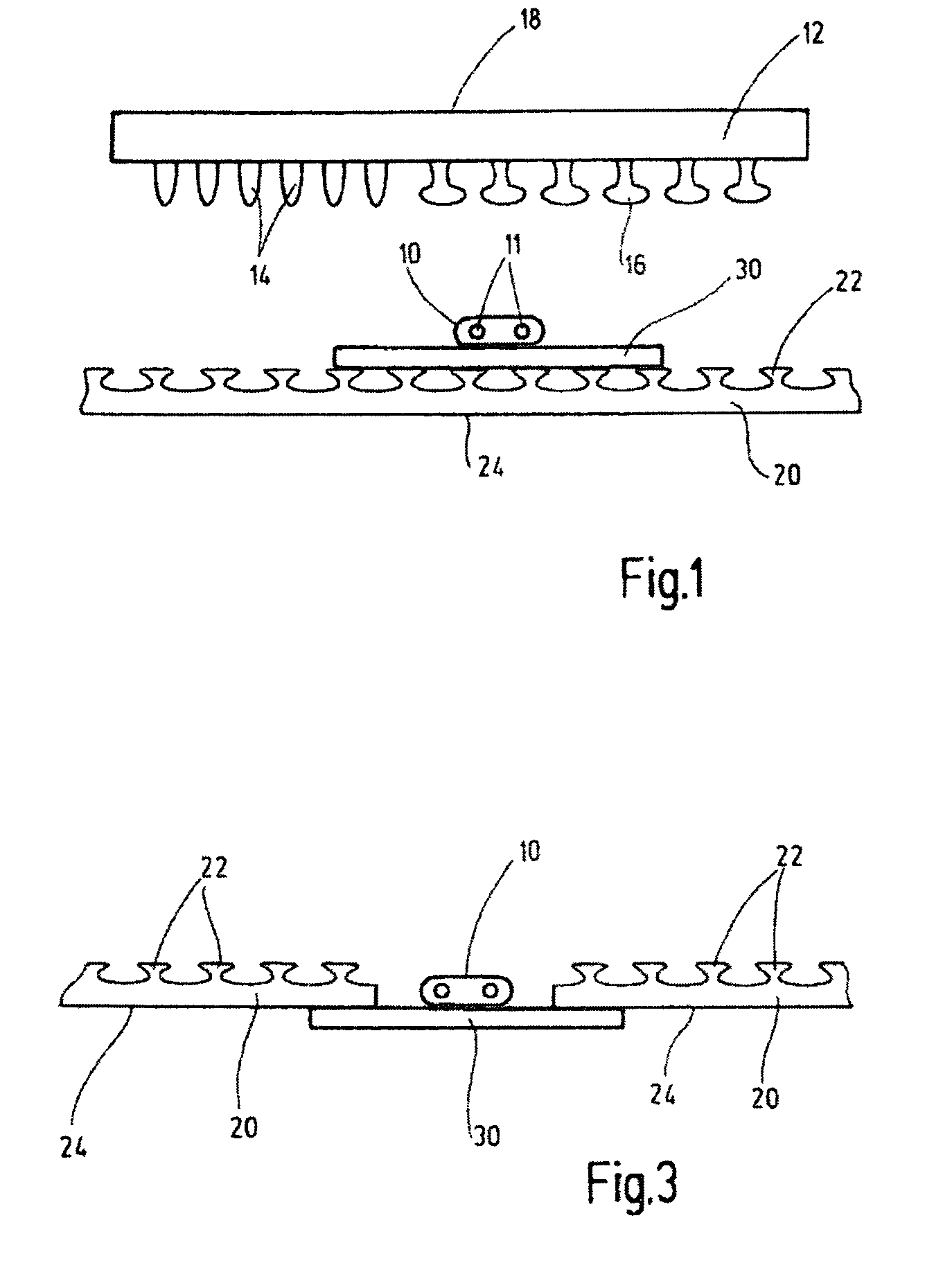

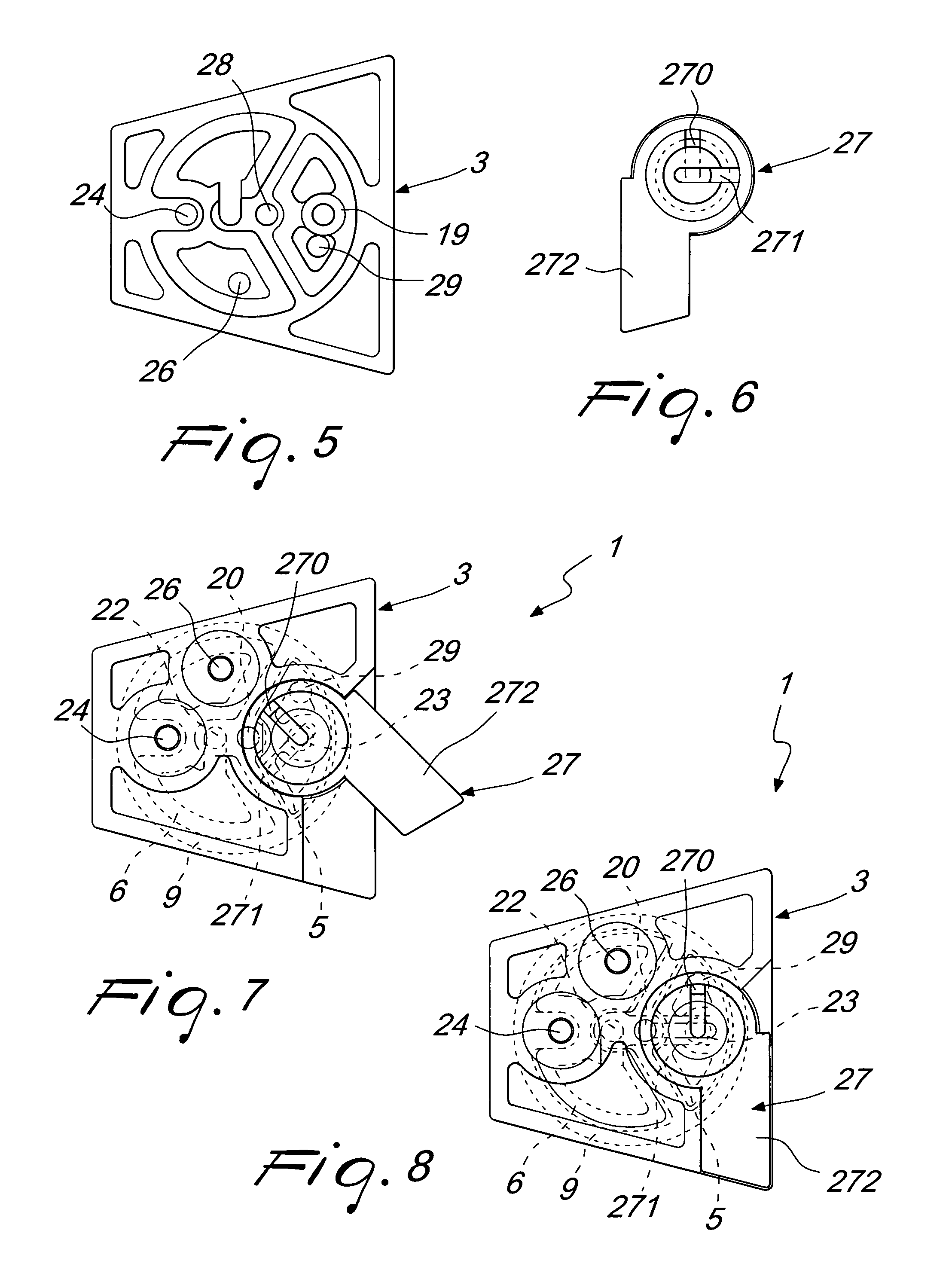

Radial sliding seal component for metering devices and metering device having such a radial sliding seal component

ActiveUS8557197B2Optimization definitionSmall geometryEngine sealsPiston ringsContact formationEngineering

The invention relates to a radial sliding seal component (10), particularly for use in metering devices, such as syringes, pipetting piston-cylinder arrangements, and the like, comprising a sealing component (12) working together with at least one pretensioning component (14), wherein the sealing component (12) comprises a sealing segment (16) extending in the axial direction and in the circumferential direction, preferably running in the circumferential direction, on which a sealing surface (18) facing in a first radial direction for sealing and sliding contact in at least the axial direction is formed on a working surface extending in the axial direction and in the circumferential direction, preferably running in the circumferential direction, and on which a pretensioning surface (20) extending in a second radial direction opposite to the first is formed for engaging with the pretensioning component (14) for transferring the radial pretensioning force, wherein the pretensioning component (14) comprises a spring carrier (26) and a plurality of separately formed radial spring segments (22) compliantly supported at least in the radial direction on the spring carrier (26).

Owner:HAMILTON BONADUZ AG

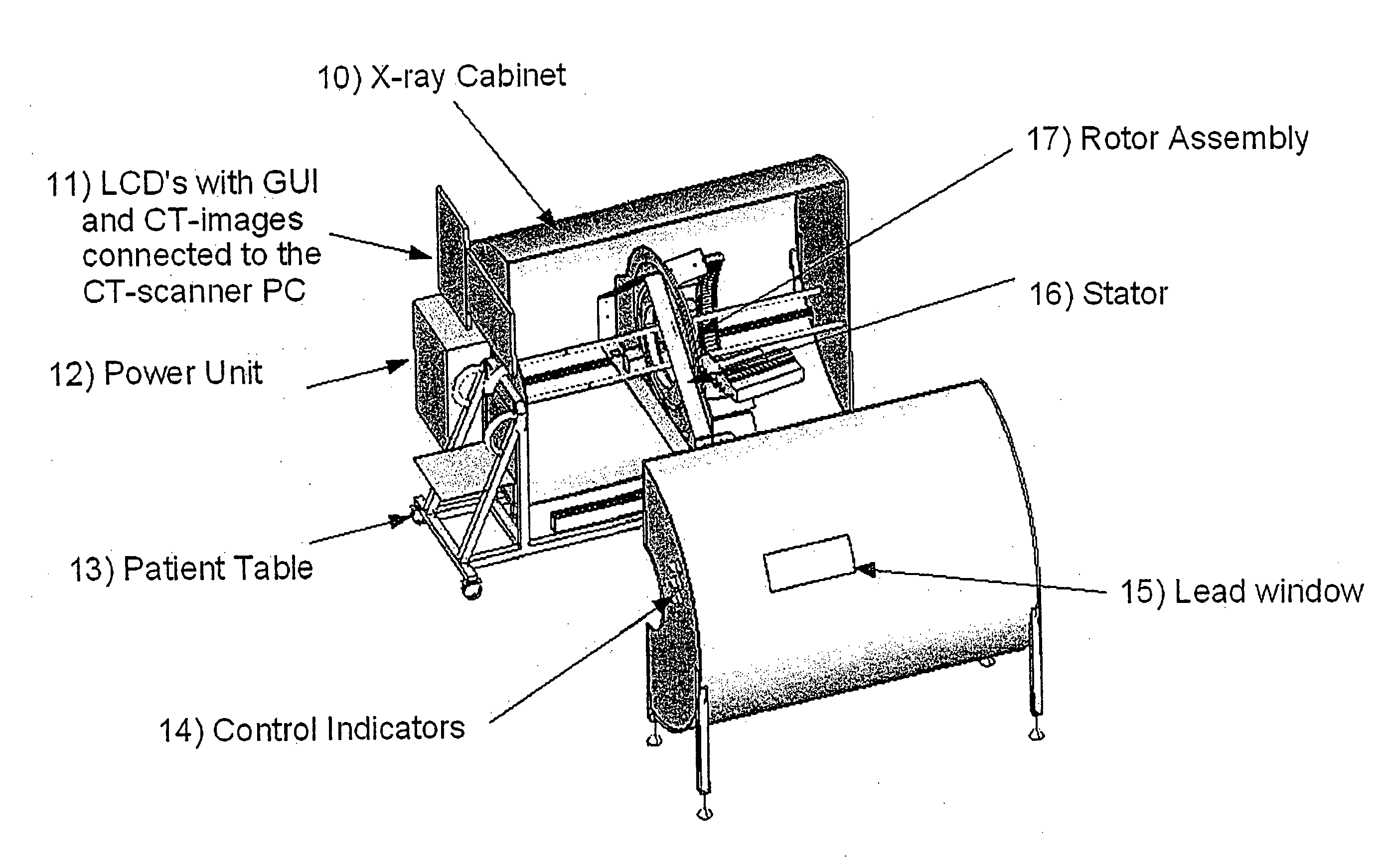

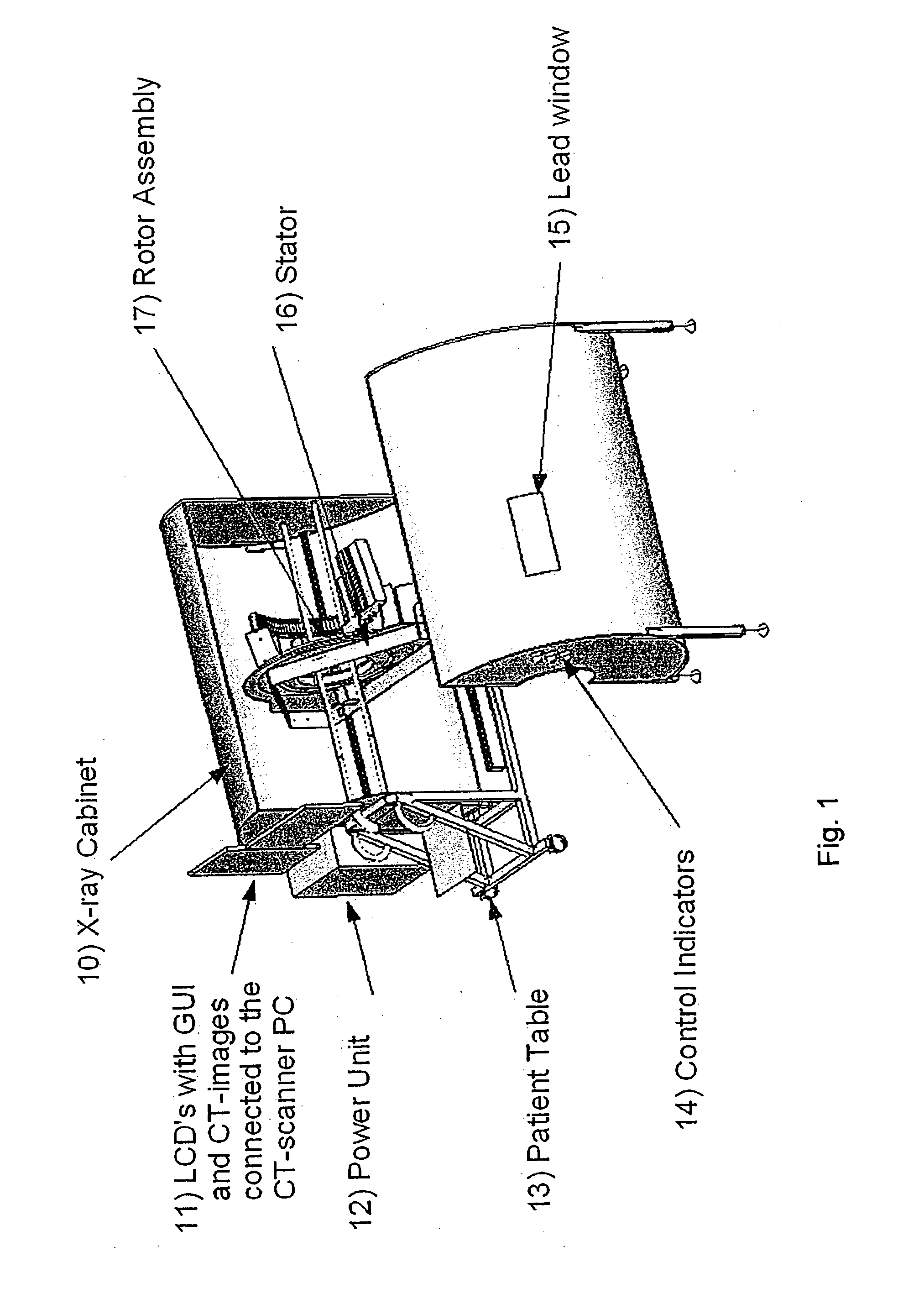

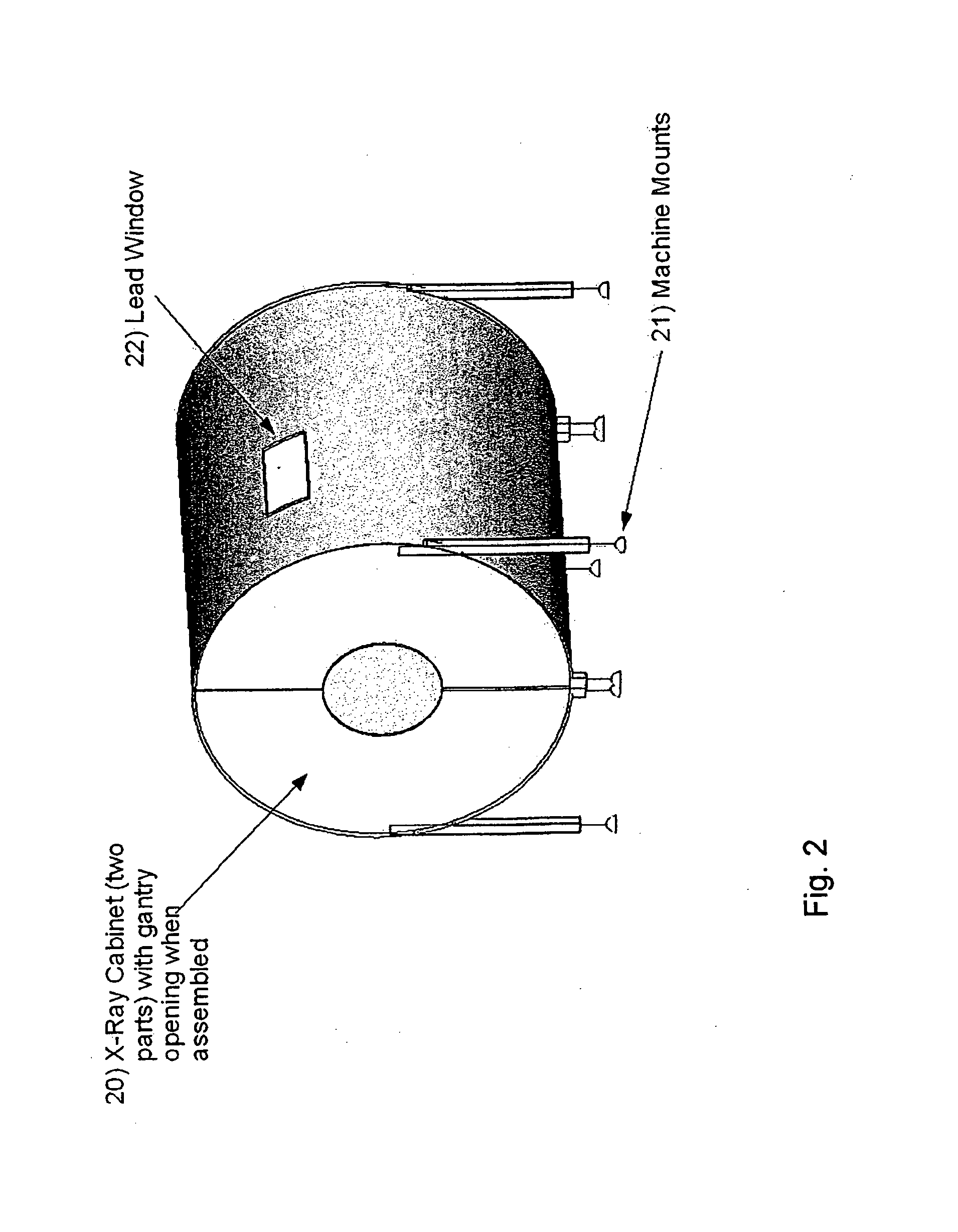

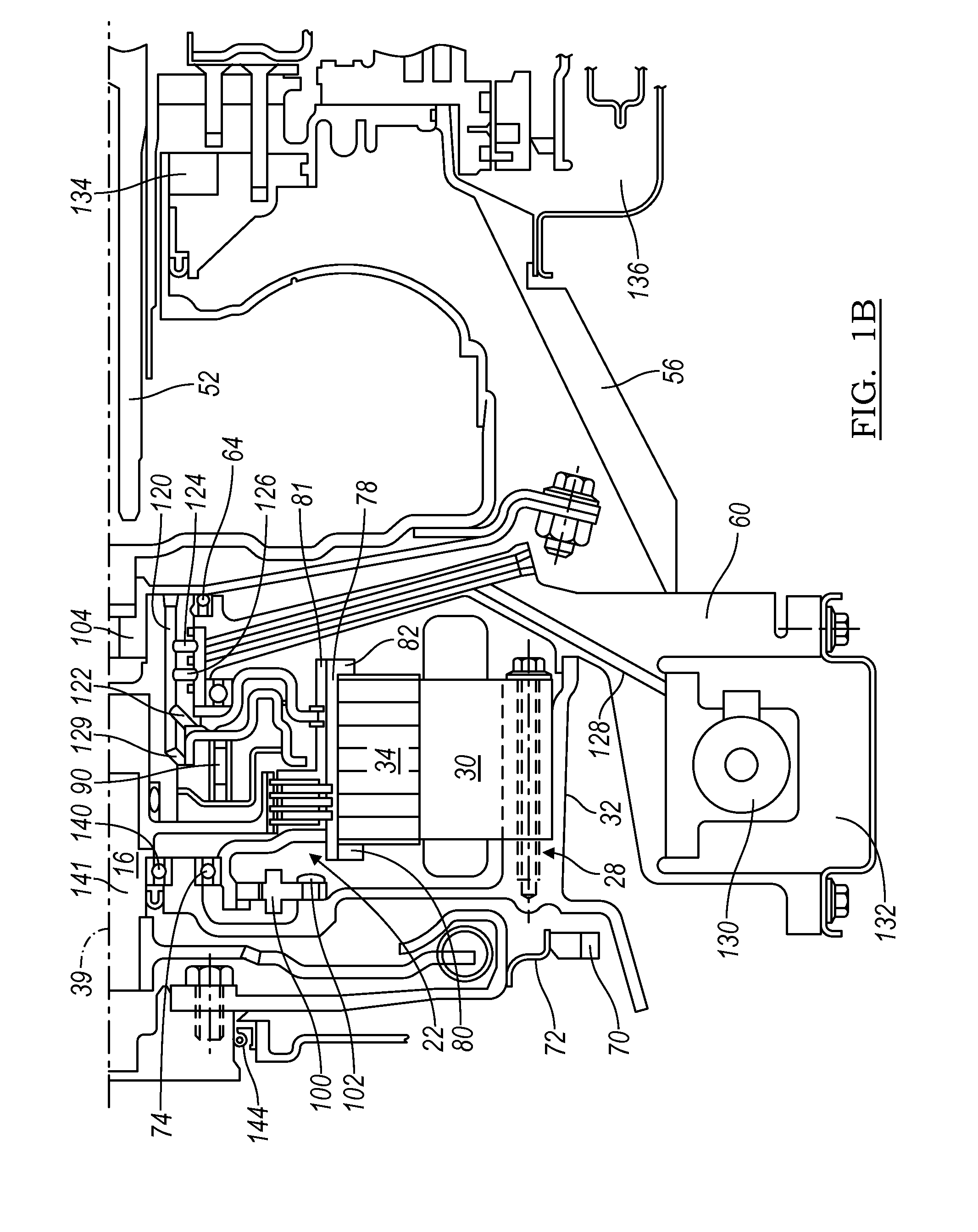

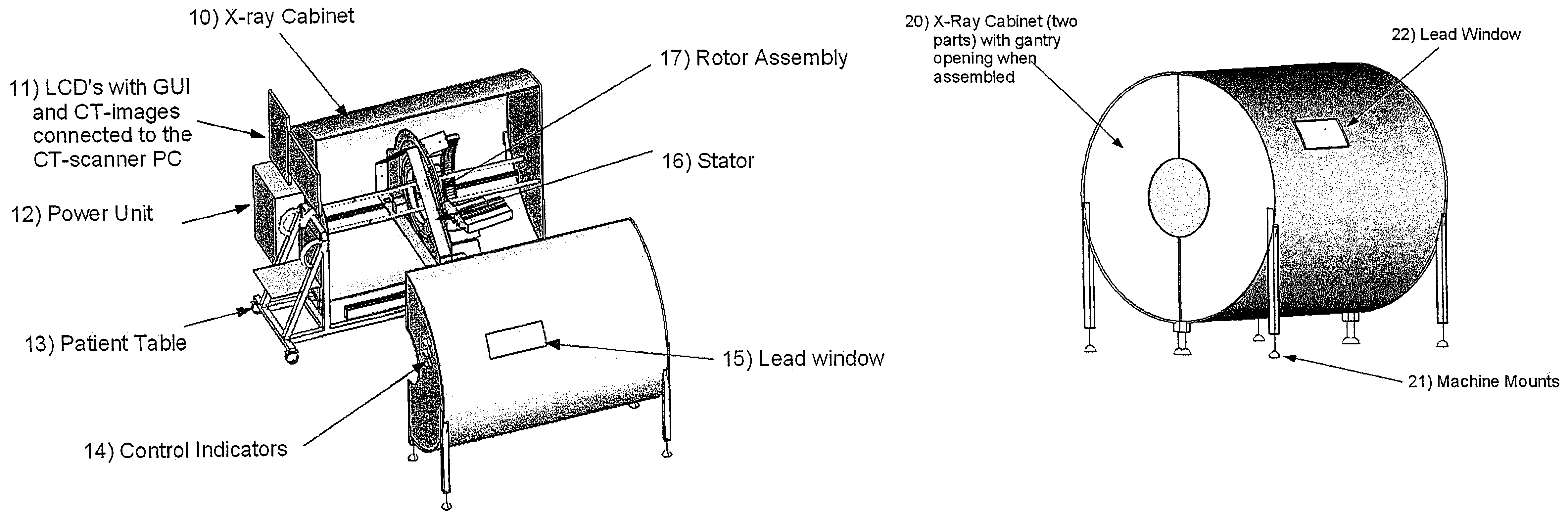

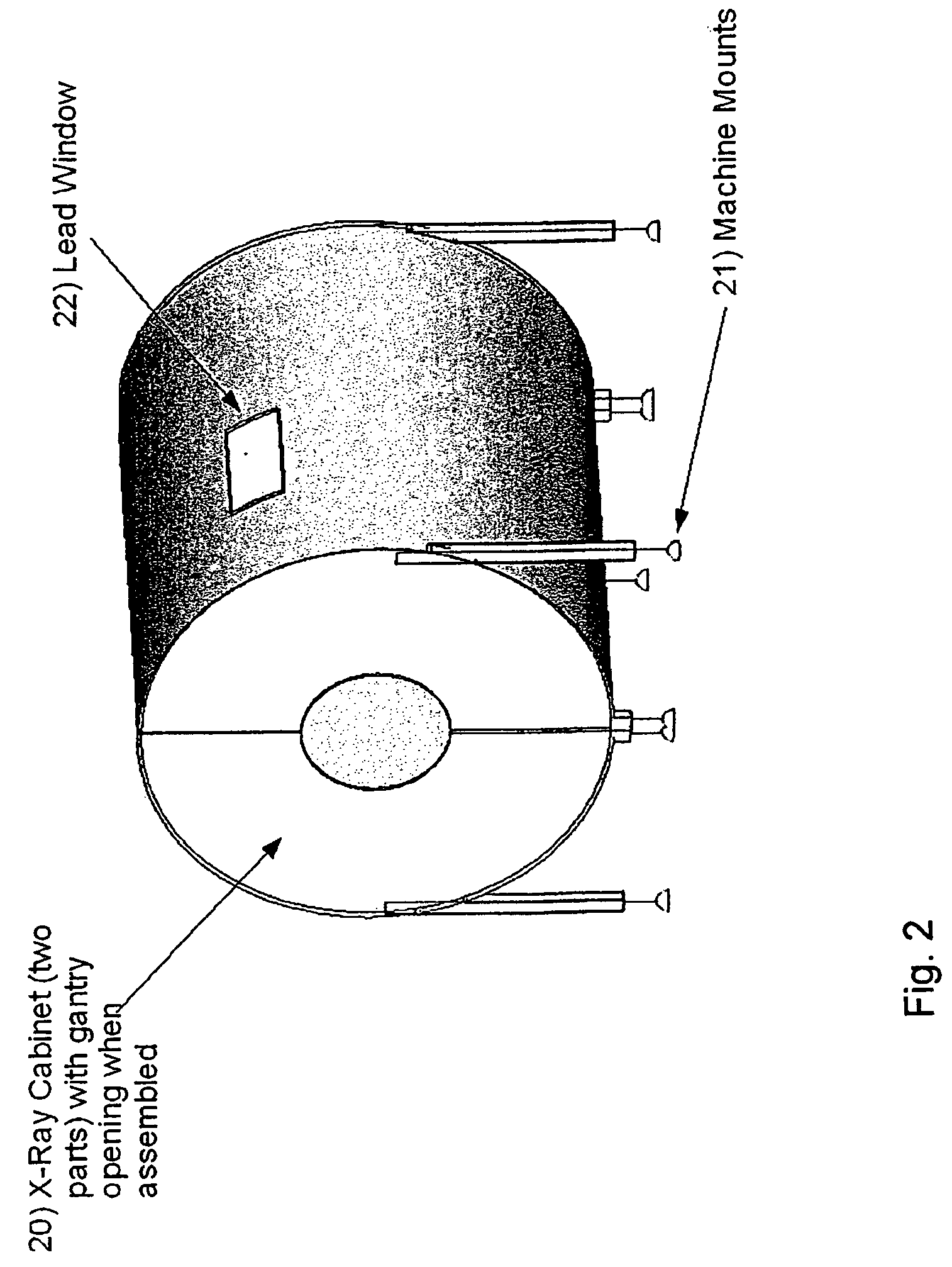

Ct scanning system

ActiveUS20110150177A1Easy to useAffordable price levelMaterial analysis using wave/particle radiationRadiation/particle handlingComputed tomographyX-ray

The present invention provides a CT scanning system having a patient table and a gantry comprising an x-ray source configured to irradiate an x-ray beam while at least partly rotating about an object being arranged on the patient table in order to be scanned. The gantry further comprises an x-ray detector configured to receive x-rays penetrating through the object to be scanned and further configured to provide output signals representative of the received x-rays. The CT scanning system further comprises an x-ray cabinet comprising x-ray shielding material. It is preferred that the x-ray cabinet is fully surrounding the gantry. The x-ray cabinet may at least partly surround the patient table. However, it is preferred that the x-ray cabinet is fully surrounding the patient table. Thus, the patient table may be configured to be fully inserted in the x-ray cabinet, whereby the x-ray cabinet is fully surrounding the patient table. The x-ray cabinet may have an end part with a patient opening allowing the introduction of a patient into the x-ray cabinet through said opening, and the CT scanning system may further comprise a closure part or door for providing an x-ray shielding closure of the patient opening at the first end part. The x-ray cabinet may be formed by at least two parts.

Owner:GNI CO LTD

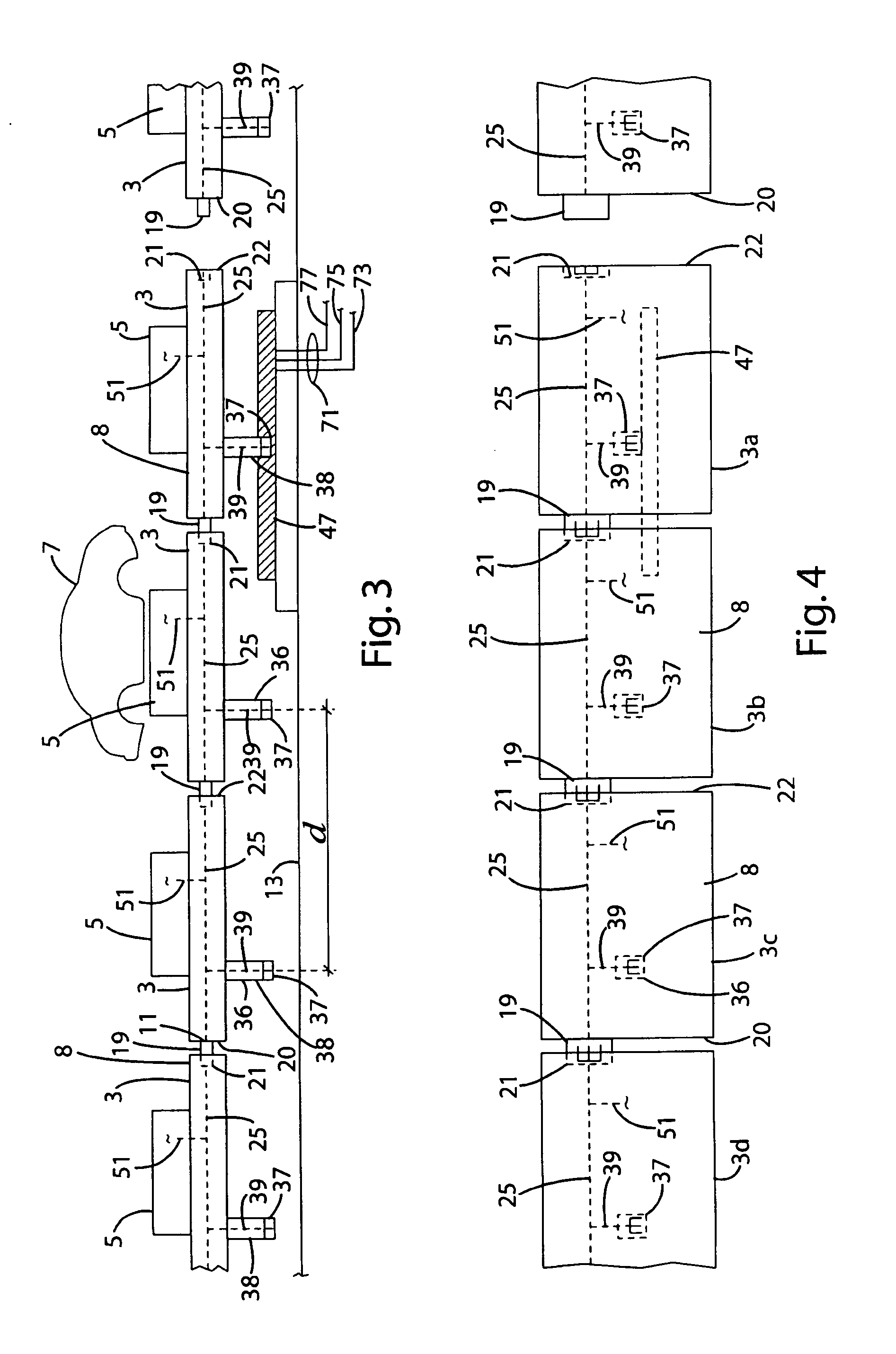

Method and apparatus for optically detecting and locating a fire in an enclosed space

ActiveUS20040213320A1Facilitate automatic and visual recognitionPossible to recognizeThermometer detailsMaterial thermal coefficient of expansionEngineeringField of view

Thermally reactive elements of an intumescent material that expands when heated above a trigger temperature are arranged in an enclosed space, e.g a freight compartment of an aircraft. An optical sensor in the enclosed space has a field of view encompassing the elements. An evolving fire heats one of the elements above the trigger temperature so the intumescent material expands. This expansion of the element is sensed by the optical sensor, for an early detection of the fire at temperatures substantially below 300° C. With the elements arranged in a predefined pattern, the location of the fire can be determined based on the element(s) that has / have expanded. The intumescent material may be an adhesive tape adhered onto the ceiling of the freight compartment. Light sources or optical targets arranged along lines of sight behind the elements enhance the unambiguous recognition of the thermally expanded condition of a respective element.

Owner:AIRBUS OPERATIONS GMBH

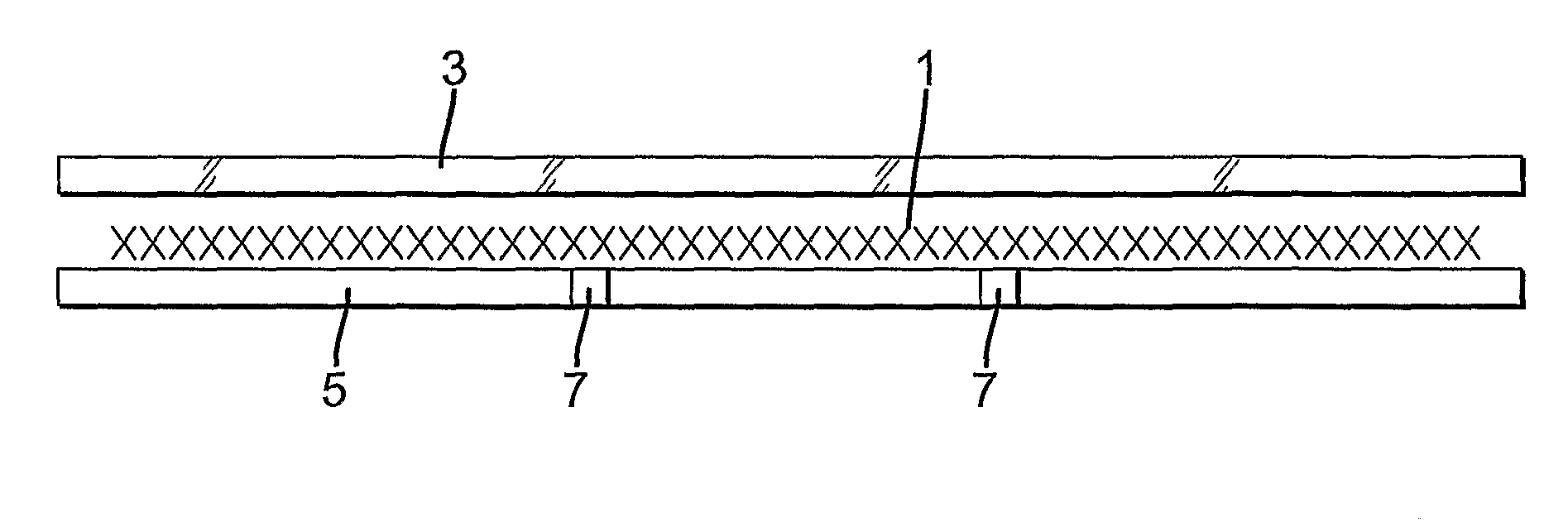

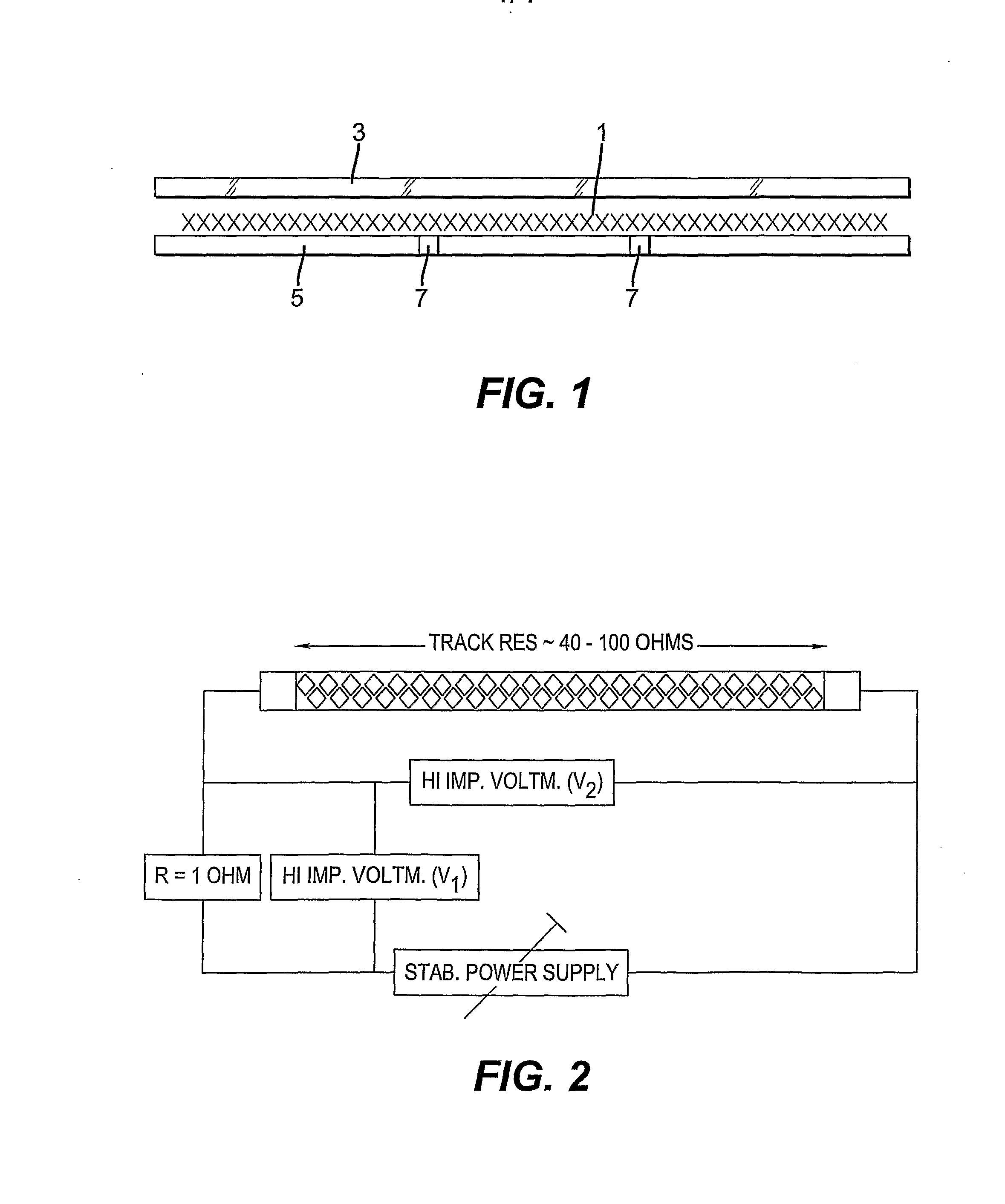

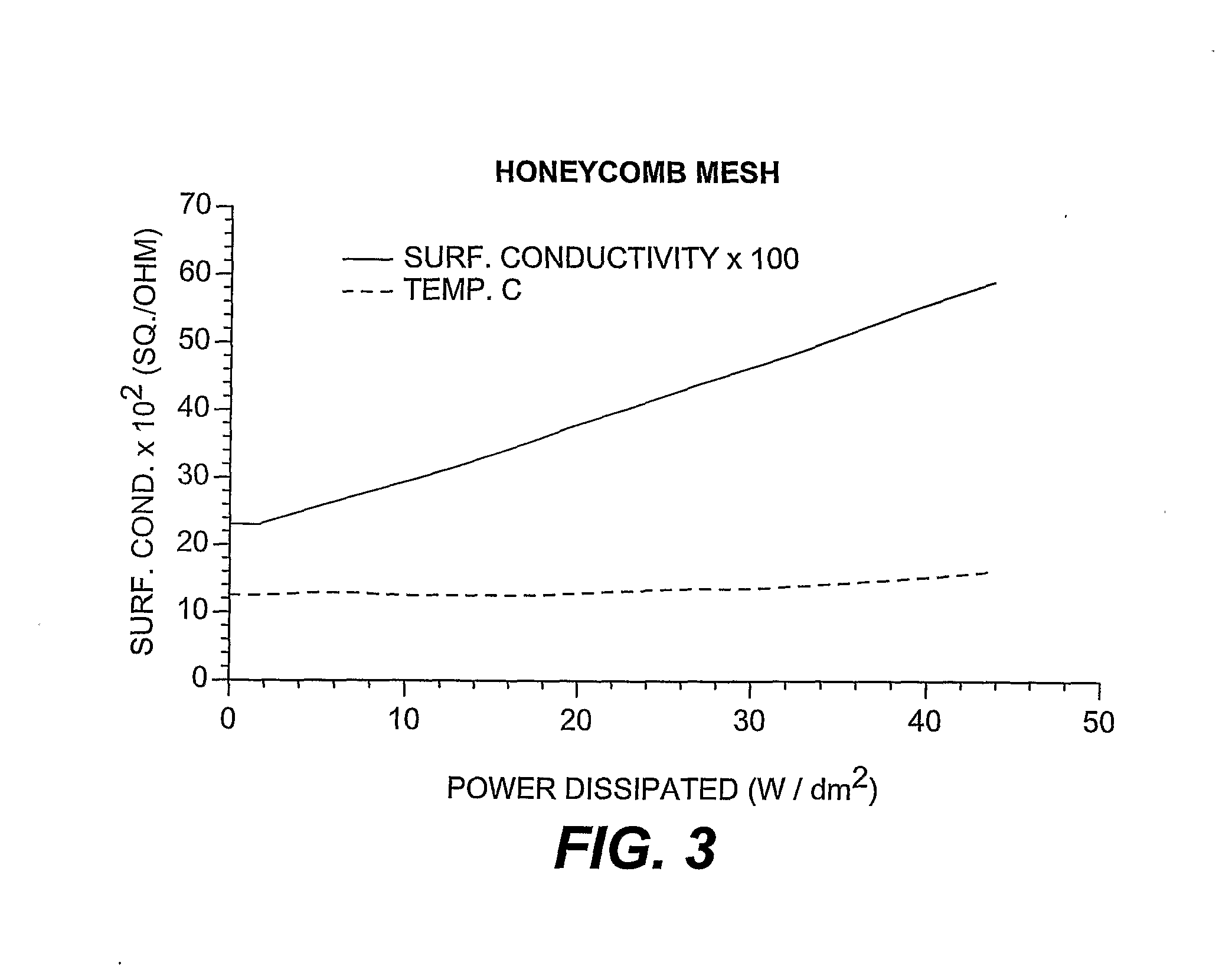

Method of Forming a Flexible Heating Element

InactiveUS20080290084A1Low production costEffectively transparentPhotosensitive materialsTransparent/reflecting heating arrangementsLatent imageEngineering

The present invention provides a method of manufacturing a heating element having a desired pattern of conductive tracks forming a power dissipative conductive track pattern with a desired resistivity and power output, the method comprising providing a photosensitive or pressure-sensitive element comprising: a support having coated on at least one side thereof a photo-sensitive or pressure-sensitive layer, which is capable of, upon imagewise radiation or pressure exposure according to the desired pattern and development of the resulting latent image, providing a metal image according to the desired pattern; imagewise radiative- or pressure-exposing the layer of the element according to a desired conductive pattern to form a latent image in the layer; and developing the element to form a conductive metal pattern, corresponding to the pattern of the latent image, on the support. The heating element may be formed on a flexible support and finds particular utility in heated window / windscreen applications.

Owner:EASTMAN KODAK CO

Method and apparatus for optically detecting and locating a fire in an enclosed space

ActiveUS7118272B2Low costLow installationThermometer detailsMaterial thermal coefficient of expansionEngineeringField of view

Thermally reactive elements of an intumescent material that expands when heated above a trigger temperature are arranged in an enclosed space, e.g a freight compartment of an aircraft. An optical sensor in the enclosed space has a field of view encompassing the elements. An evolving fire heats one of the elements above the trigger temperature so the intumescent material expands. This expansion of the element is sensed by the optical sensor, for an early detection of the fire at temperatures substantially below 300° C. With the elements arranged in a predefined pattern, the location of the fire can be determined based on the element(s) that has / have expanded. The intumescent material may be an adhesive tape adhered onto the ceiling of the freight compartment. Light sources or optical targets arranged along lines of sight behind the elements enhance the unambiguous recognition of the thermally expanded condition of a respective element.

Owner:AIRBUS OPERATIONS GMBH

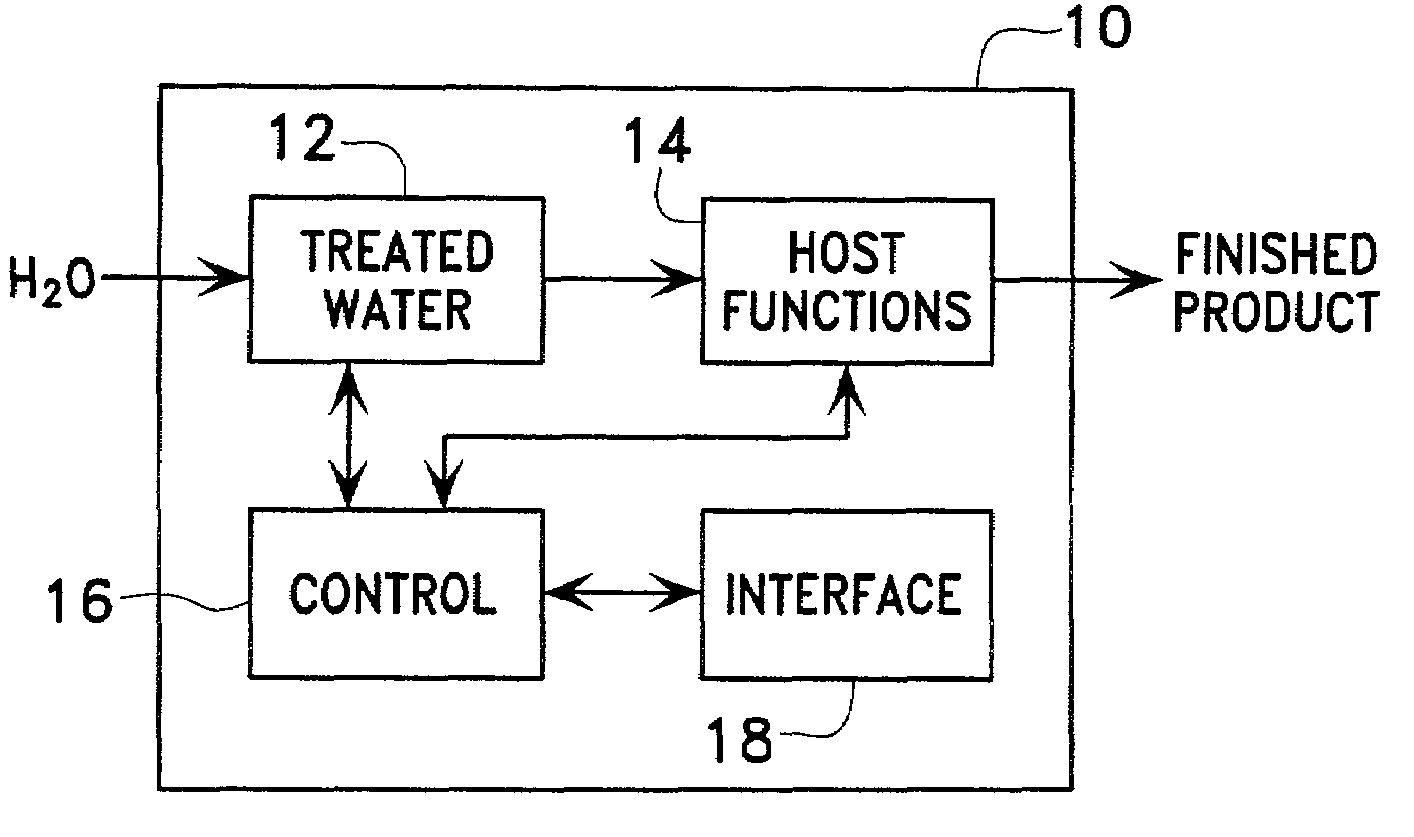

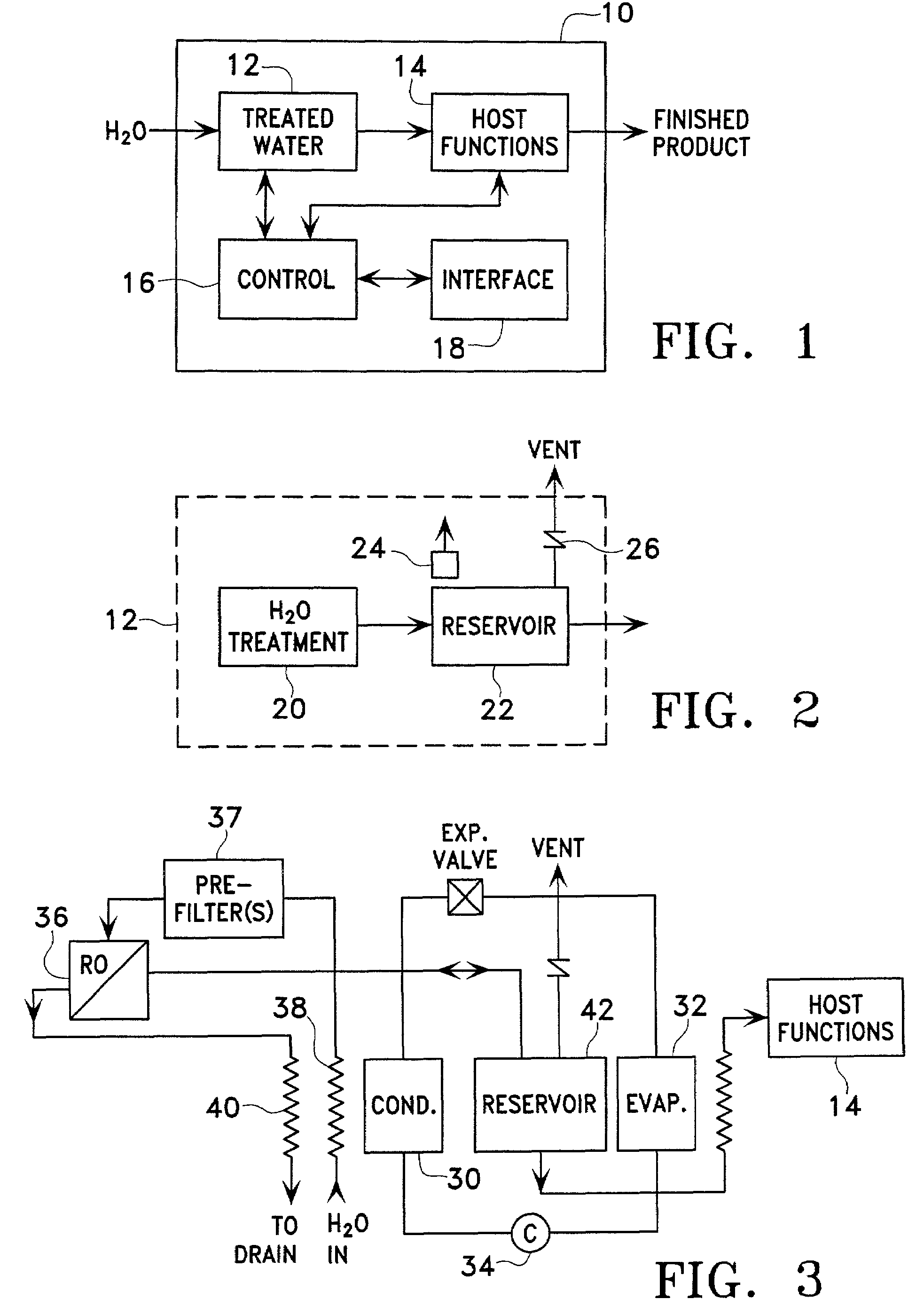

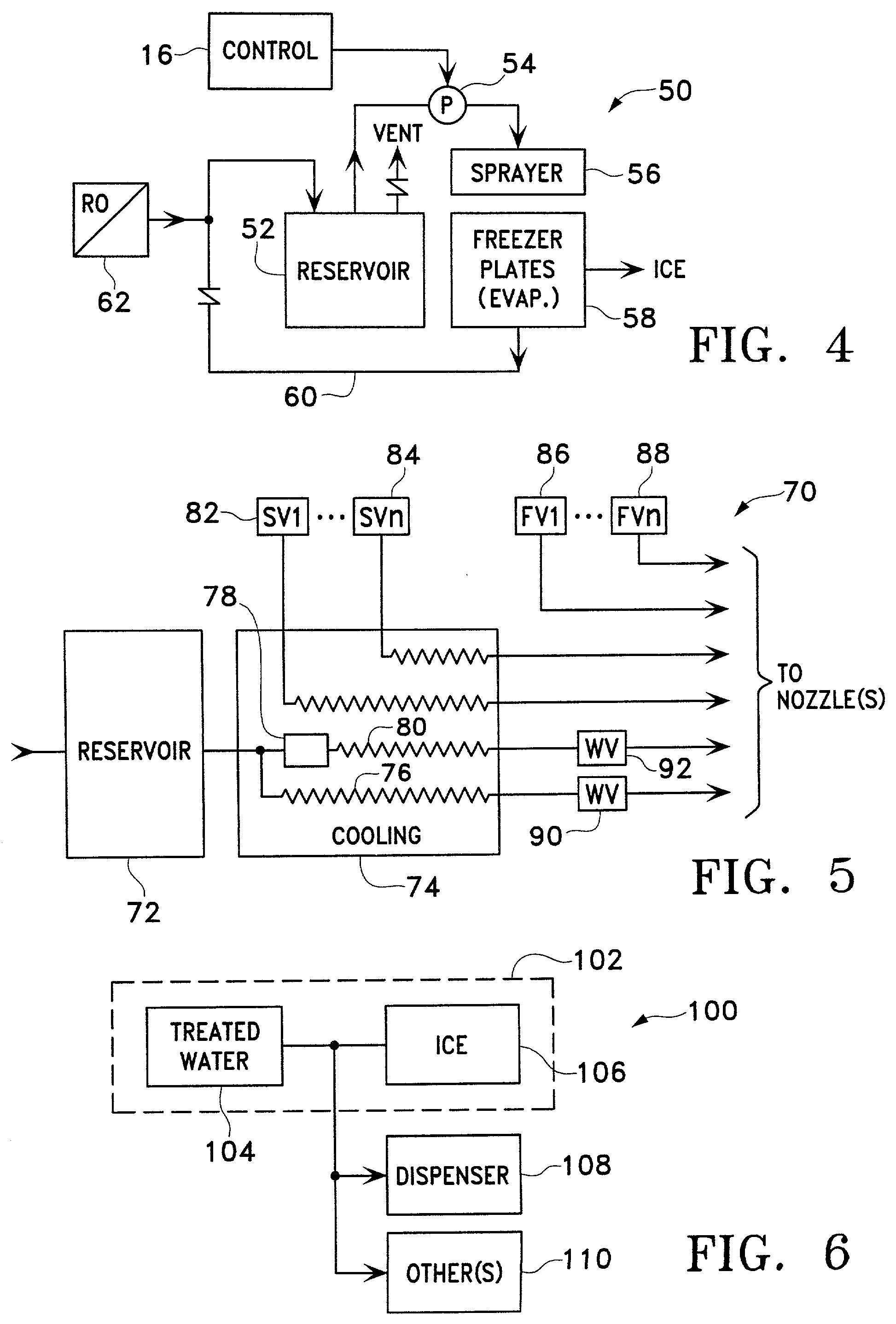

Systems and methods with treated water

InactiveUS7264731B2Eliminate and reduce problemLow costLighting and heating apparatusSedimentation separationWater sourceEnvironmental engineering

Units (10), systems (100), and methods with treated water are provided in which a treated water source (12, 104) is included integrally in a host piece of equipment (10, 102). The host piece of equipment (10, 102) includes host functions such as ice making (14, 106). Other equipment, such as dispenser (108) may be coupled to the equipment (102) to share the treated water from treated water source (104).

Owner:BOSKO ROBERT S

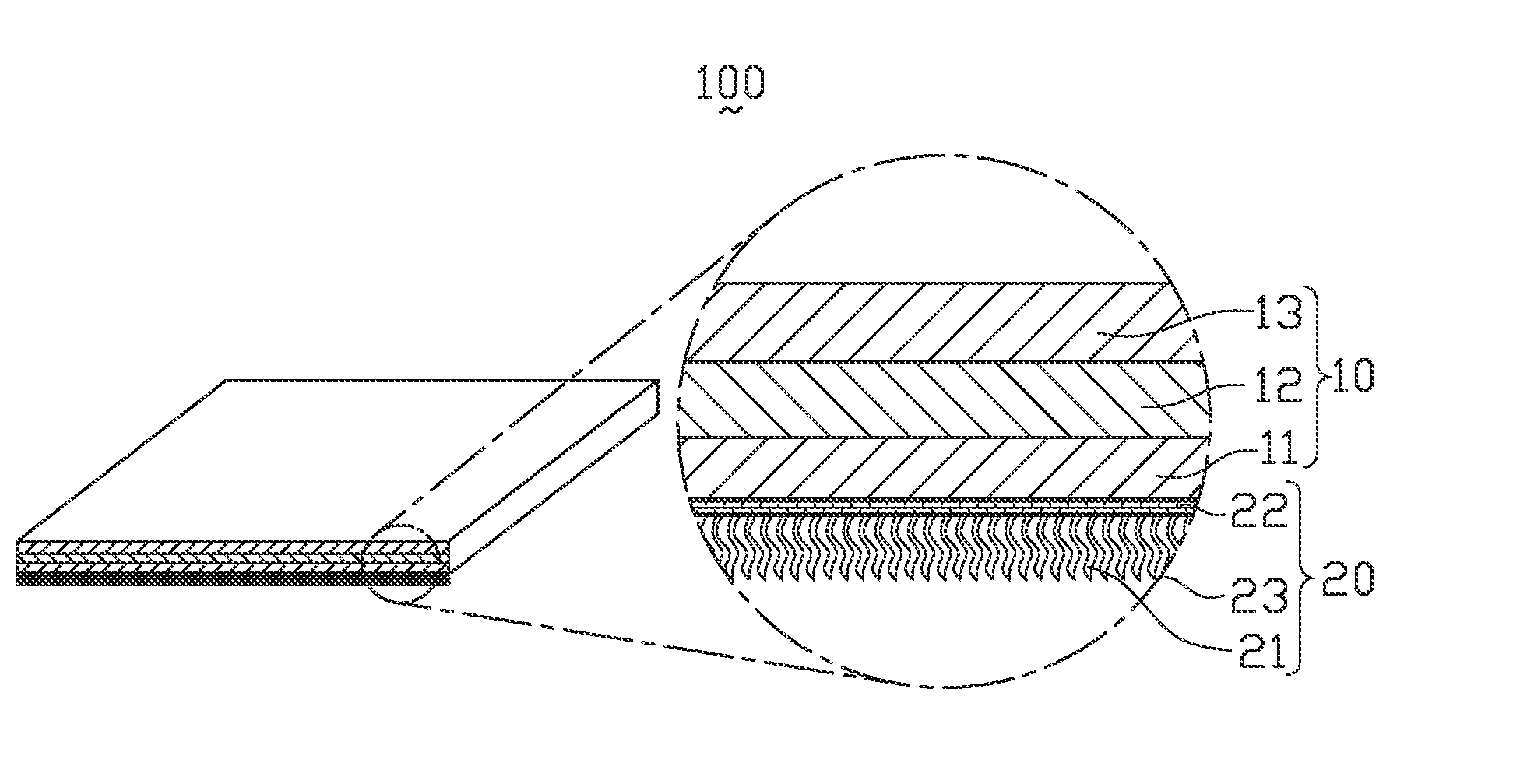

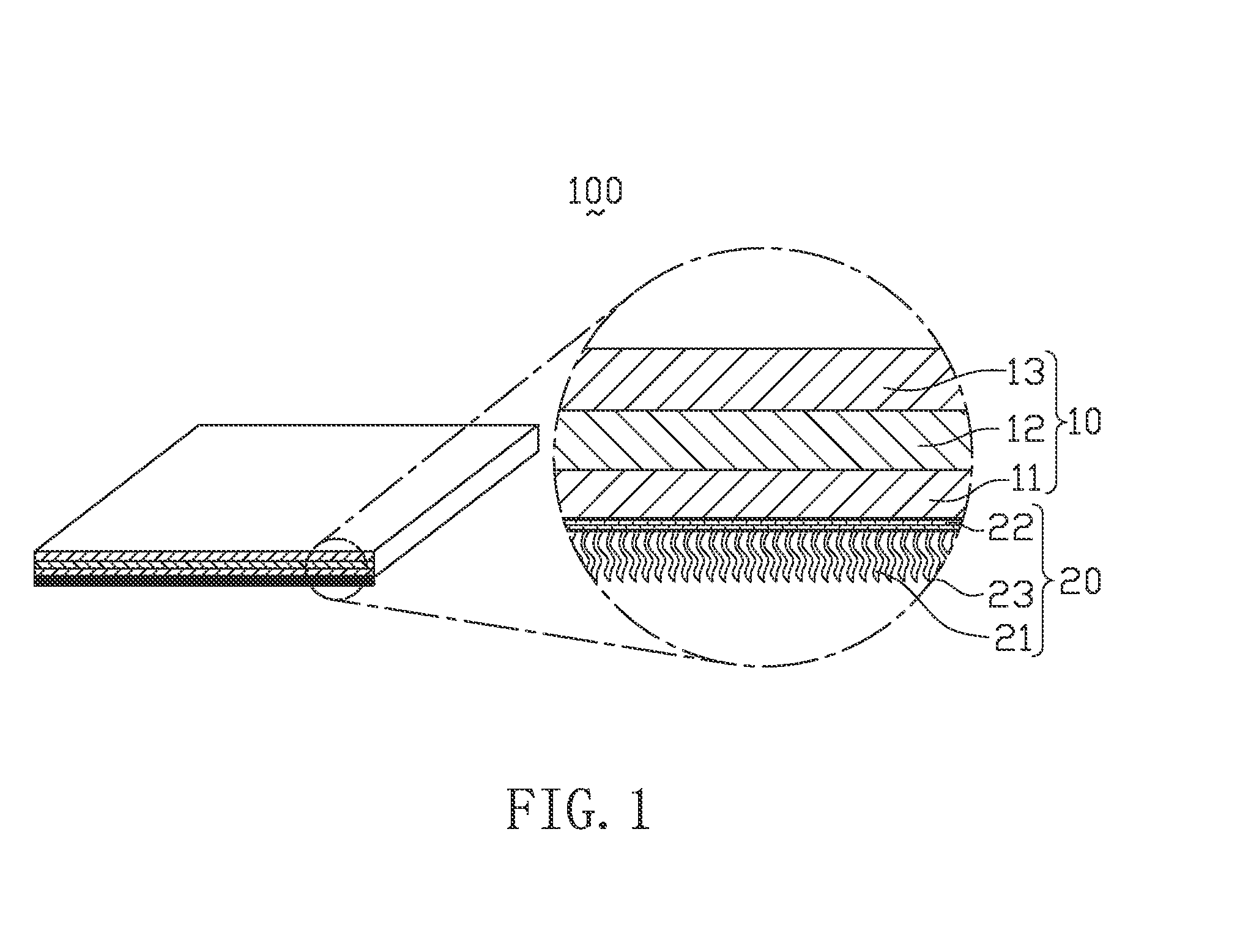

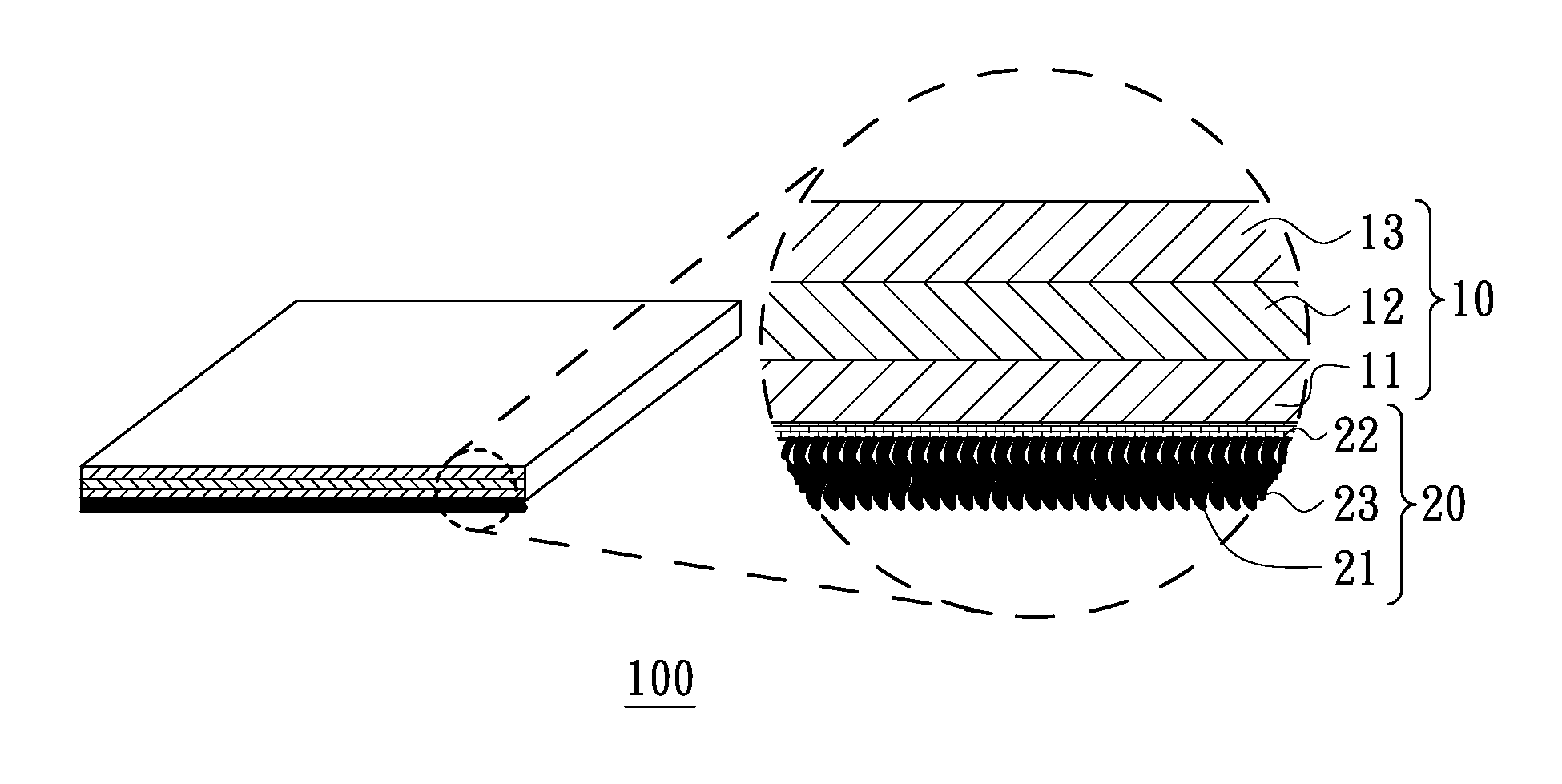

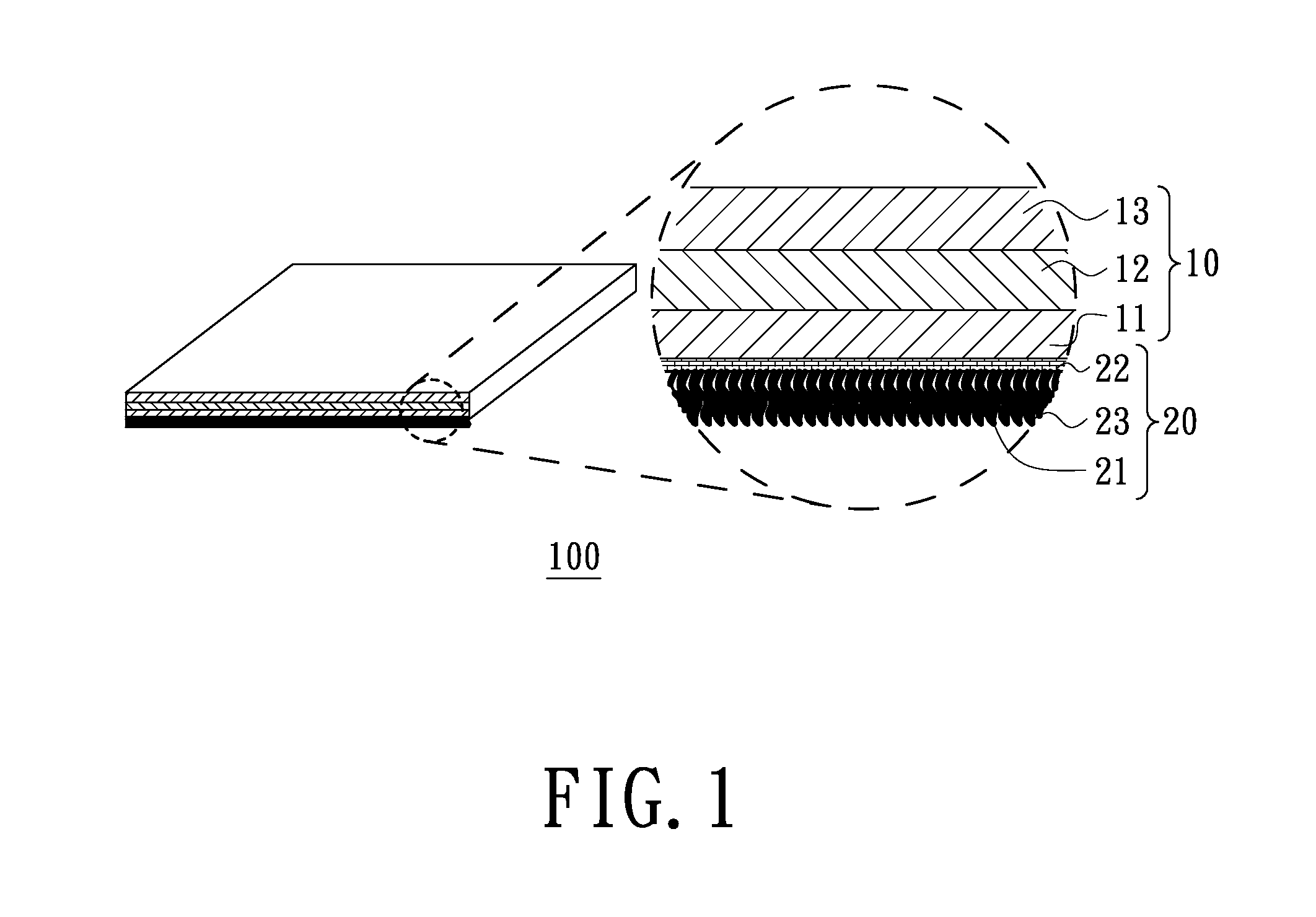

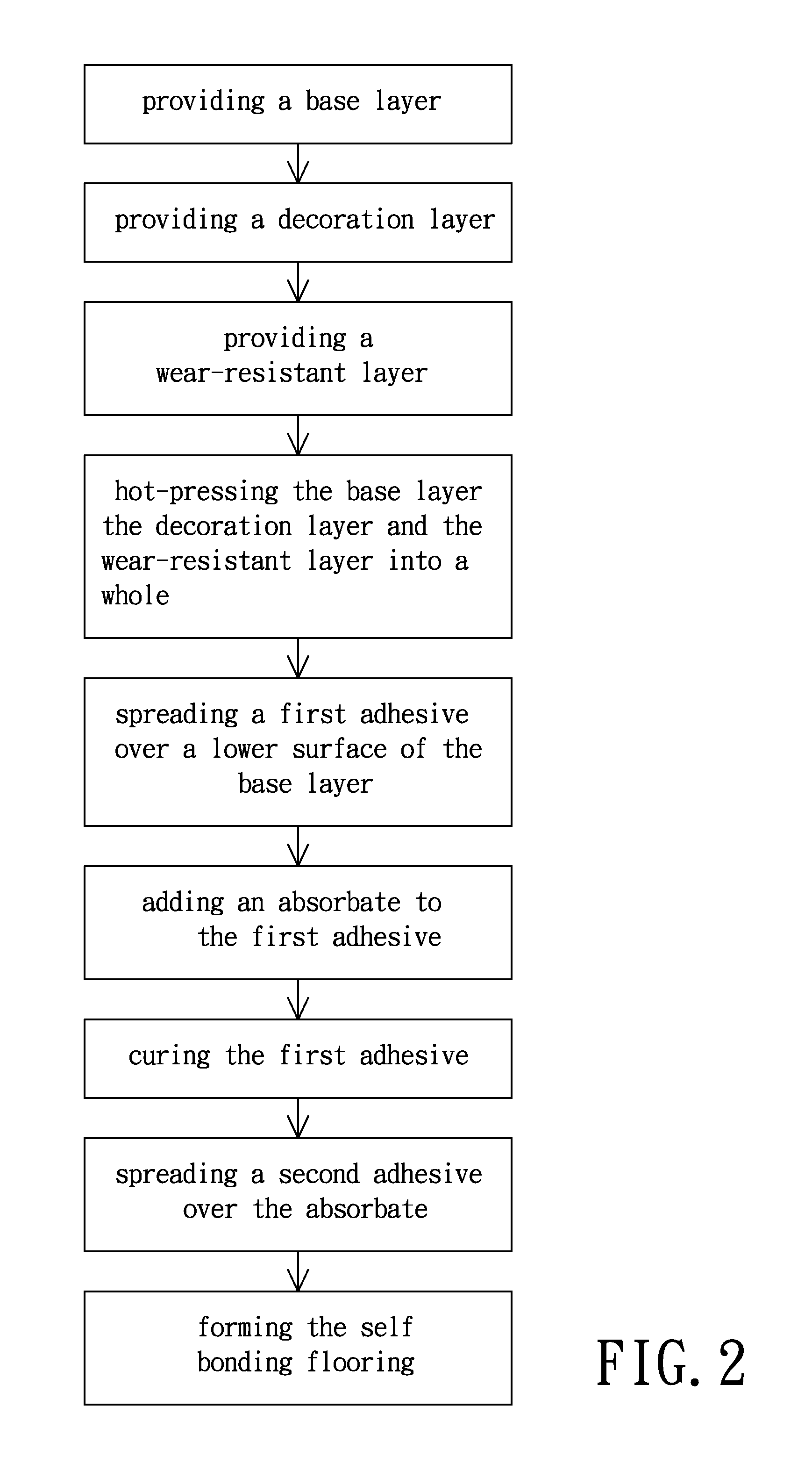

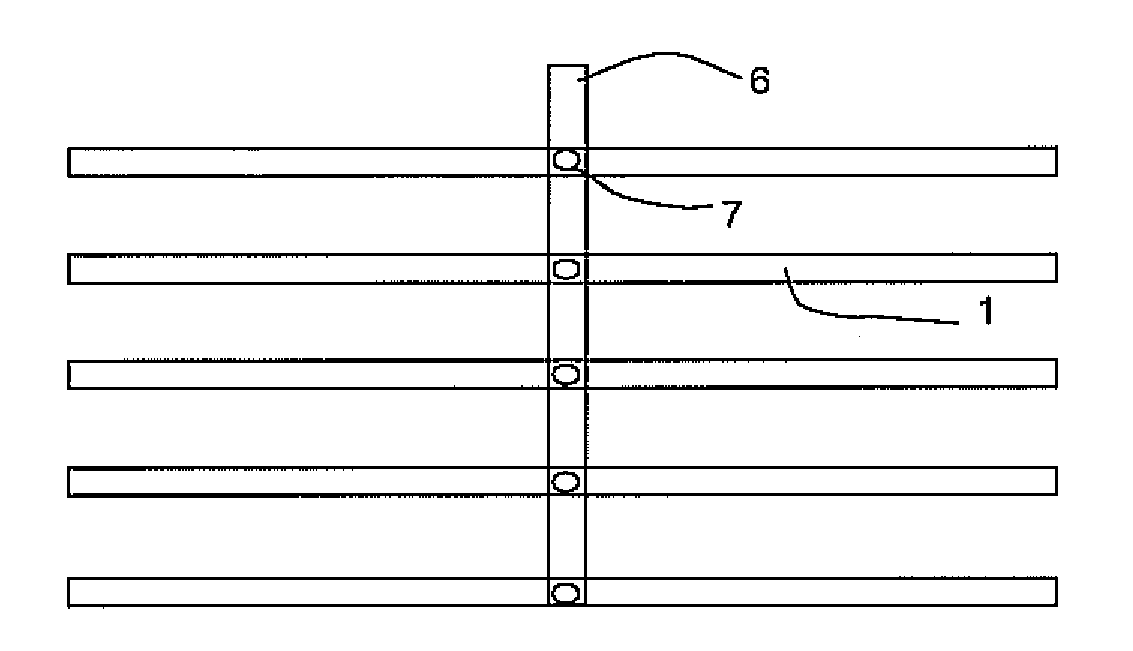

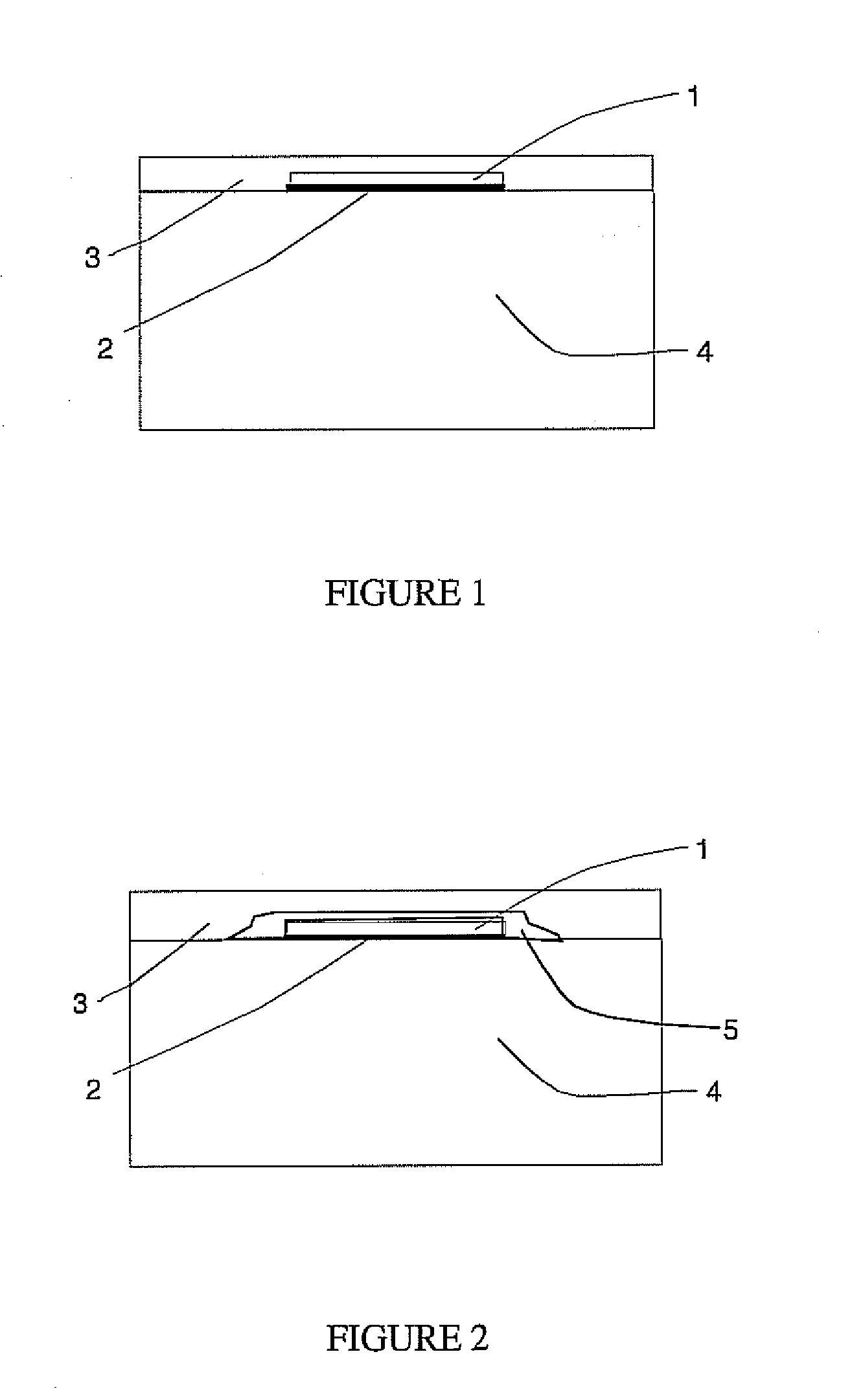

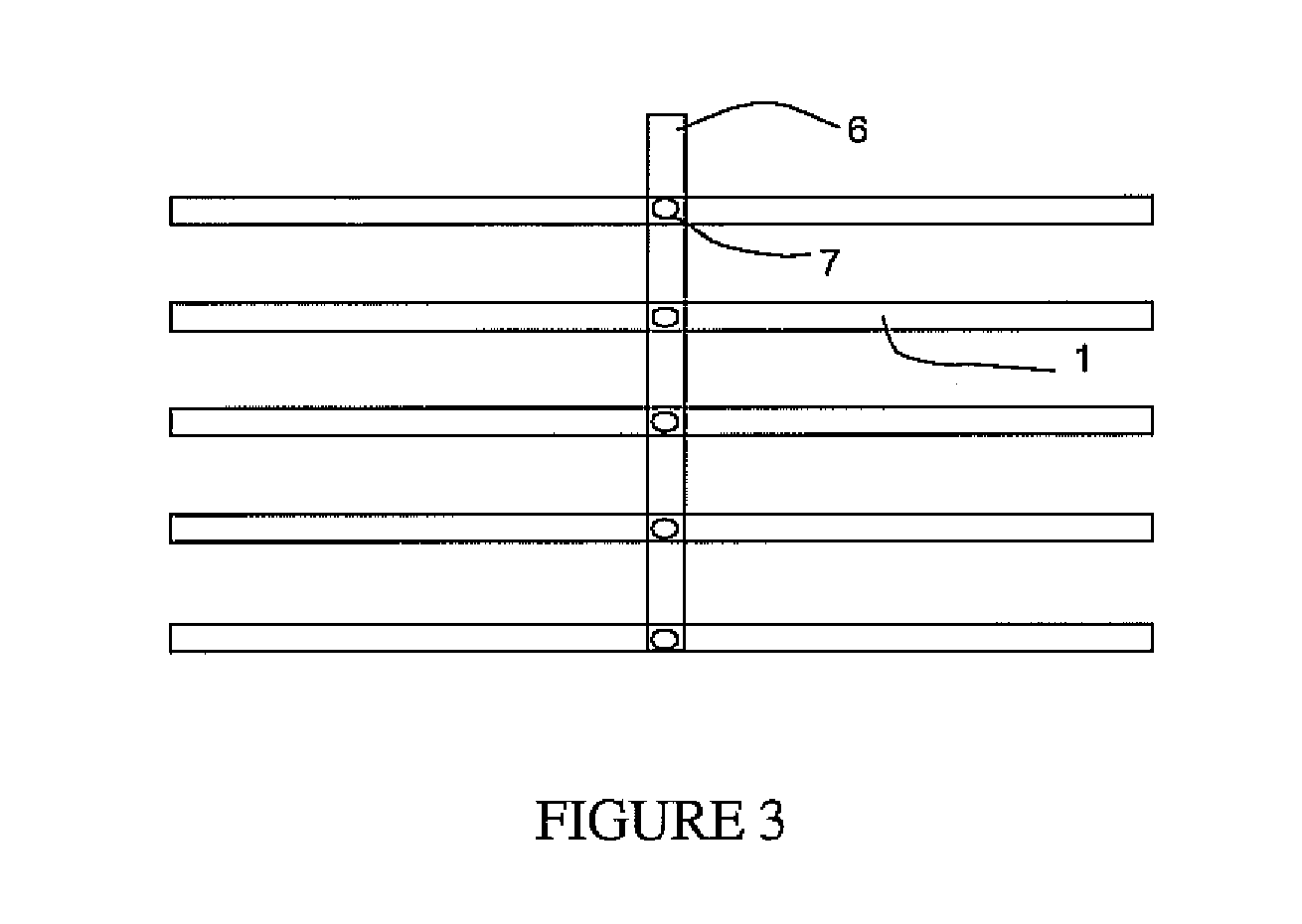

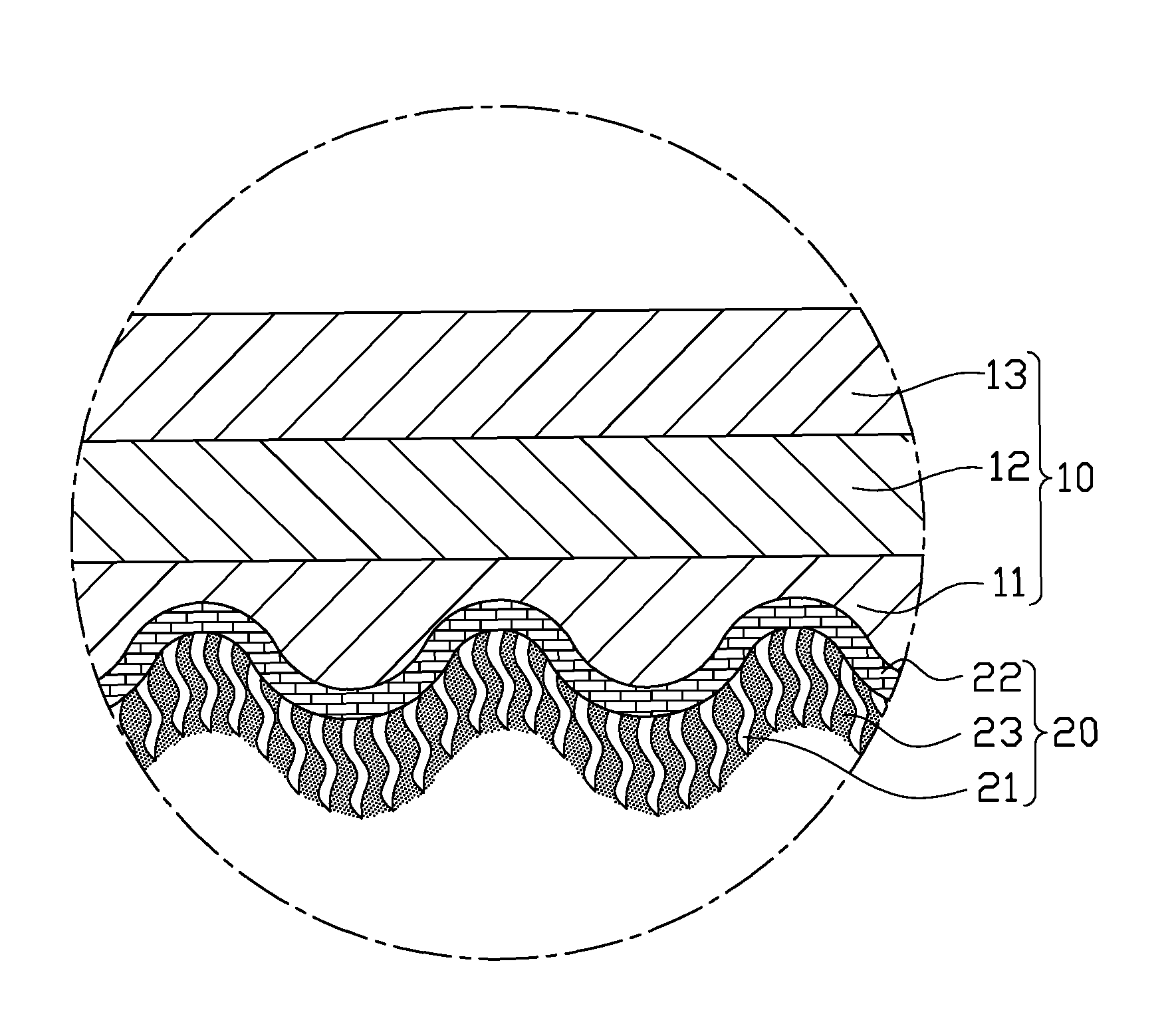

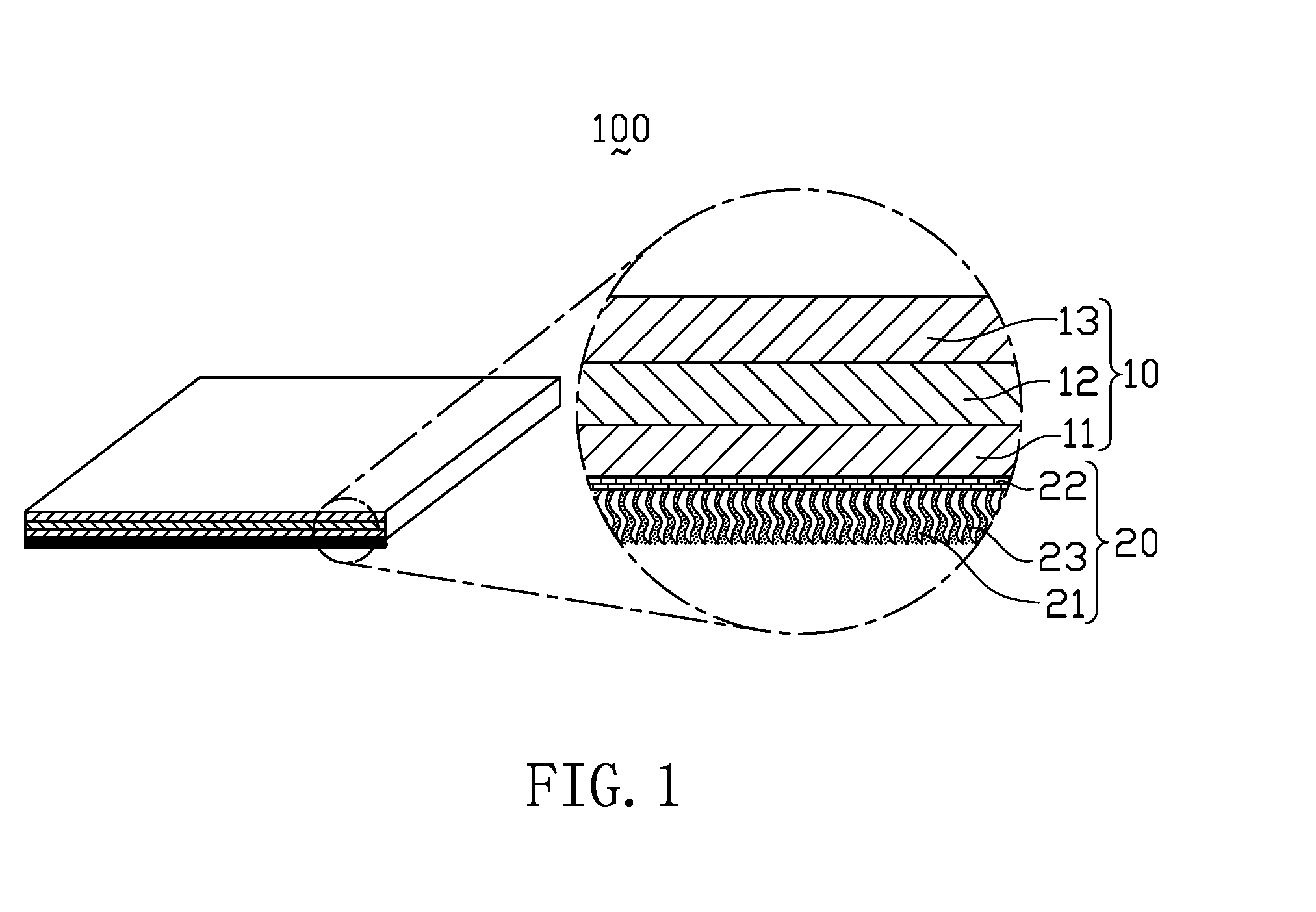

Self bonding floor tile

ActiveUS20140227475A1Easy to disassembleThe removal process is simpleConstruction materialLayered productsFiberAdhesive

A self bonding floor tile includes a main body and a self bonding layer connected with the main body. The self bonding layer includes an absorptive element, a first adhesive and a second adhesive. The first adhesive connects the main body with the self bonding layer. The absorptive element includes a plurality of fibers which are implanted into the first adhesive by flocking process with at least a portion of the absorptive element extending into the first adhesive, and at least a portion of the second adhesive penetrates into the other portion of the absorptive element for connecting the self bonding layer with a support body going to be decorated. The present self bonding floor tile can be quickly installed, easily and partly replaced with low installation and replacement cost.

Owner:FLOORING IND LTD

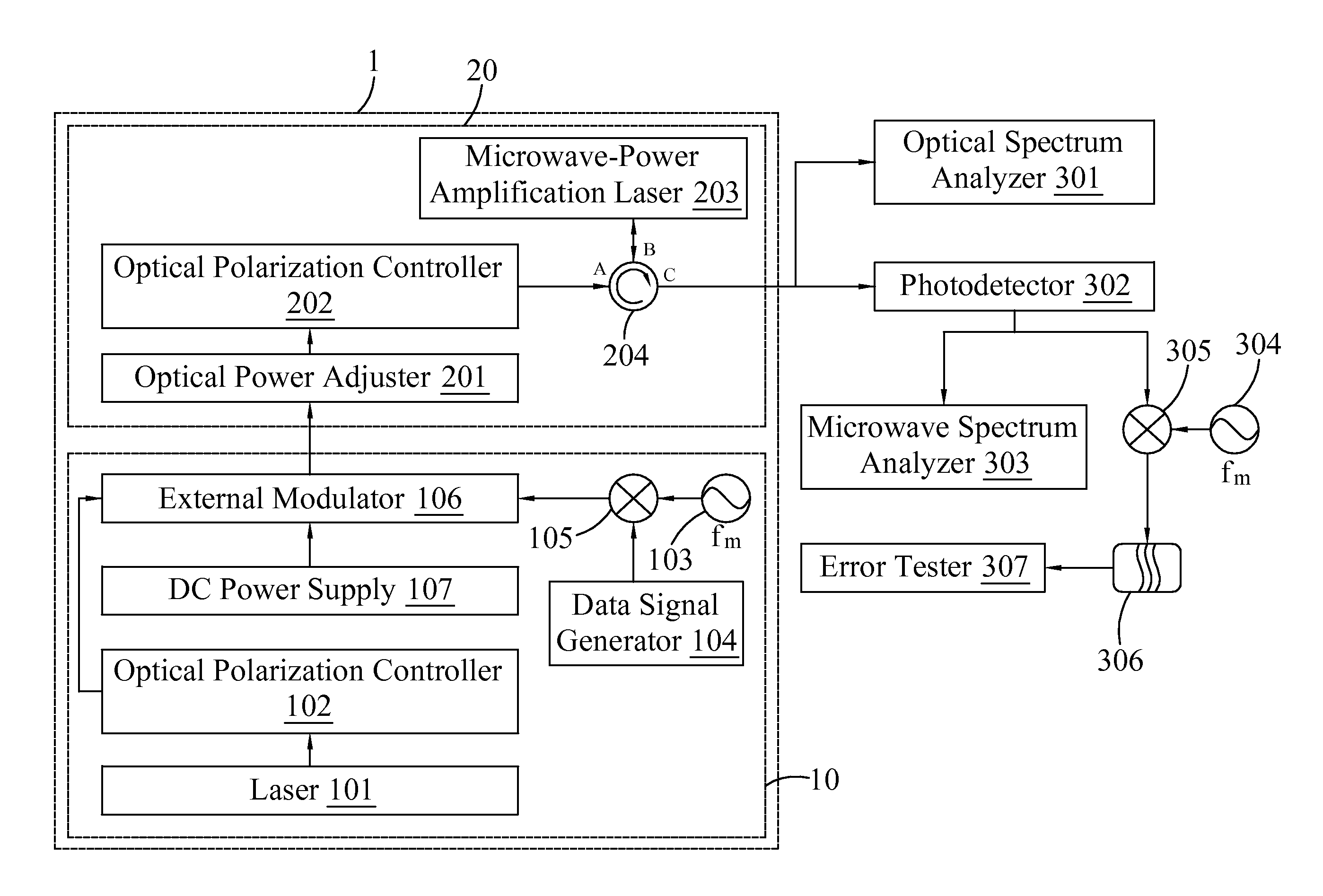

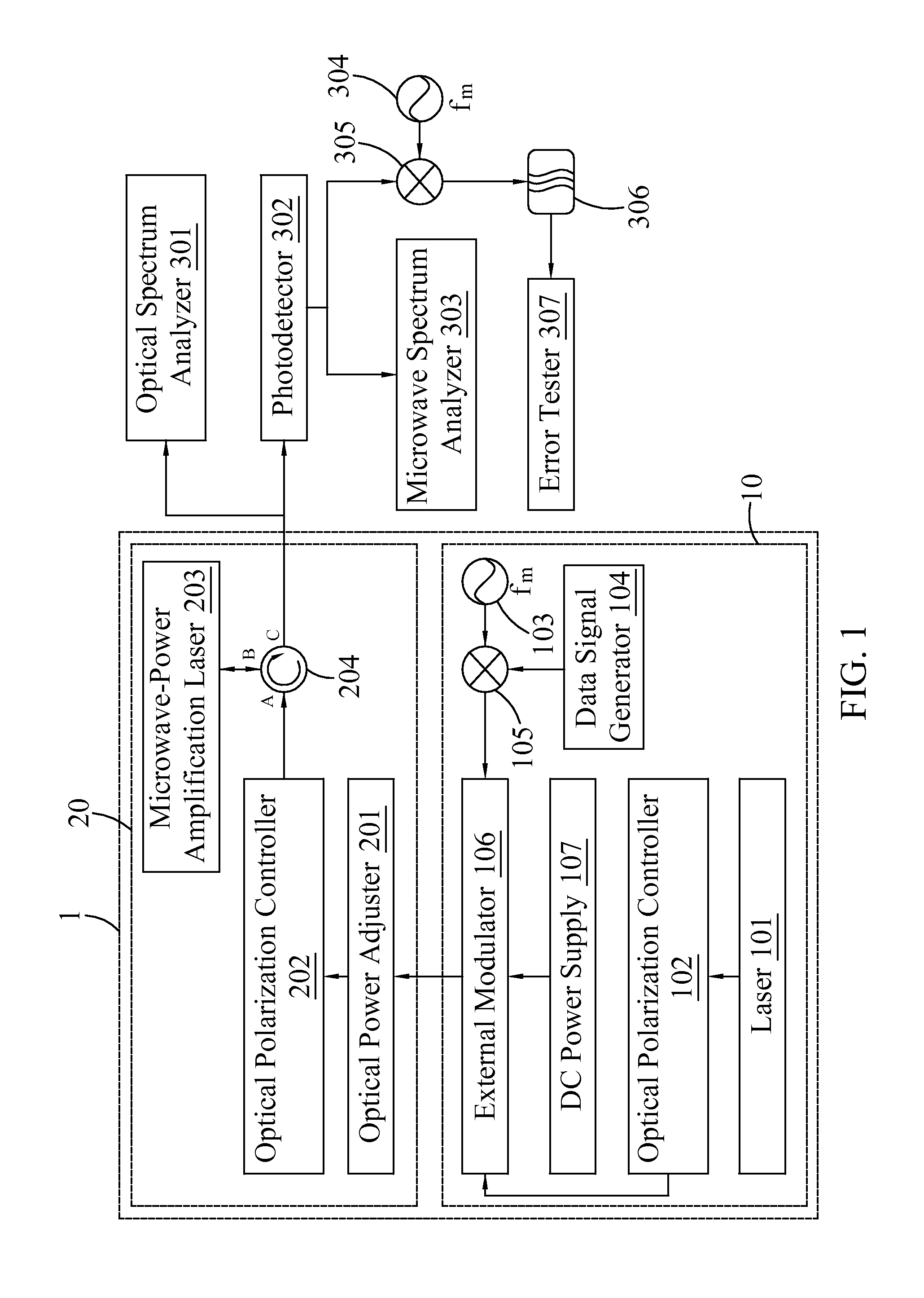

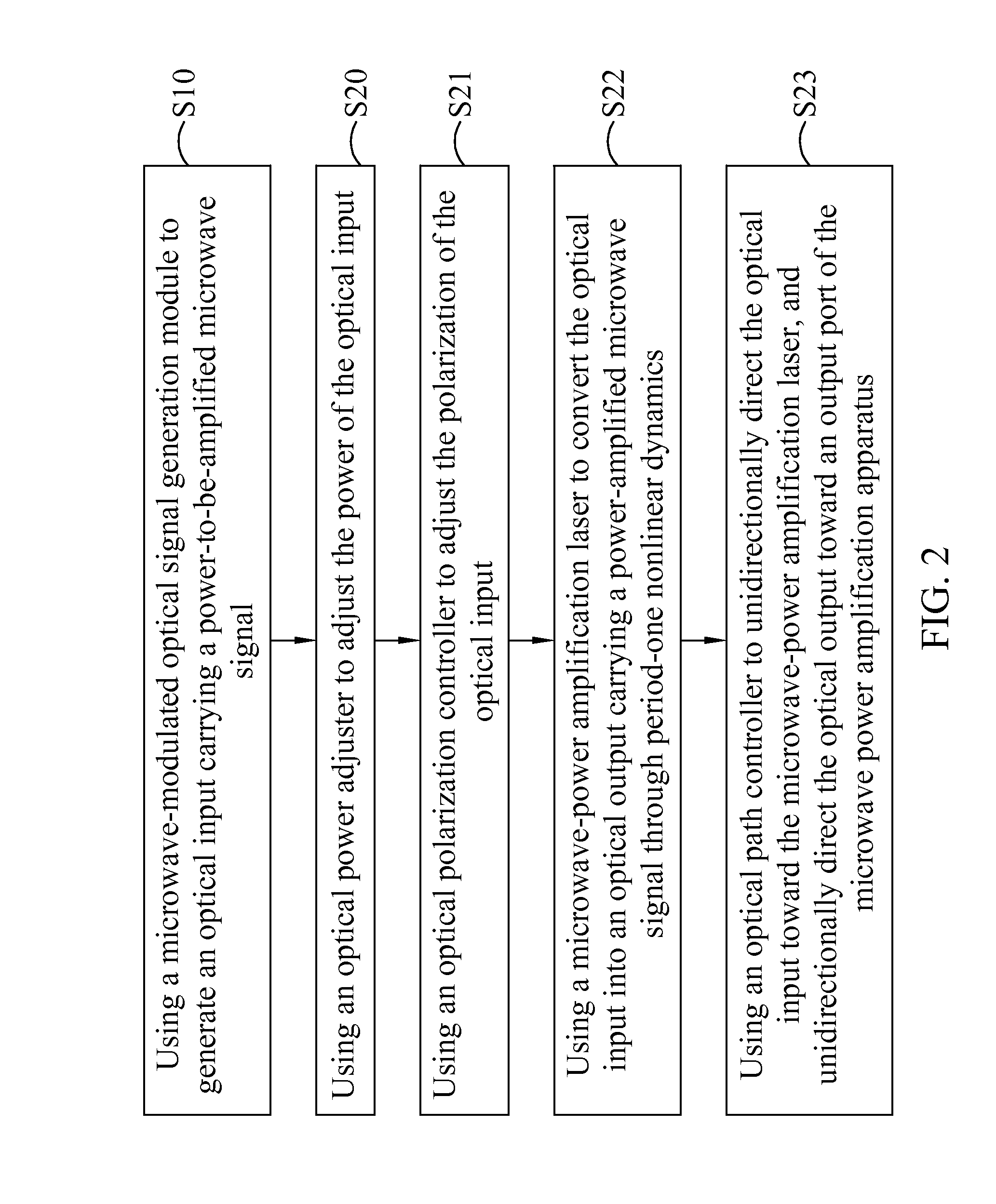

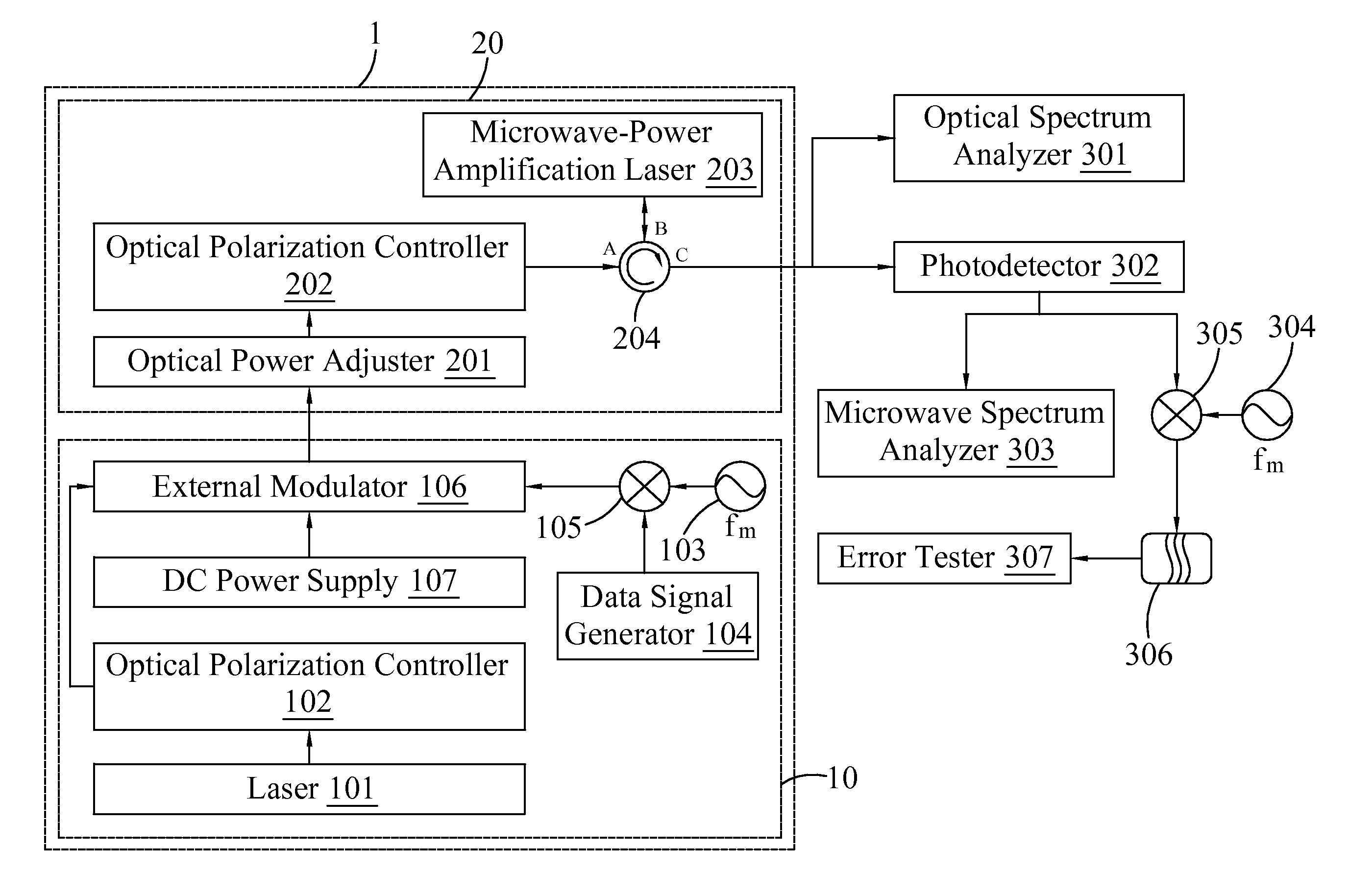

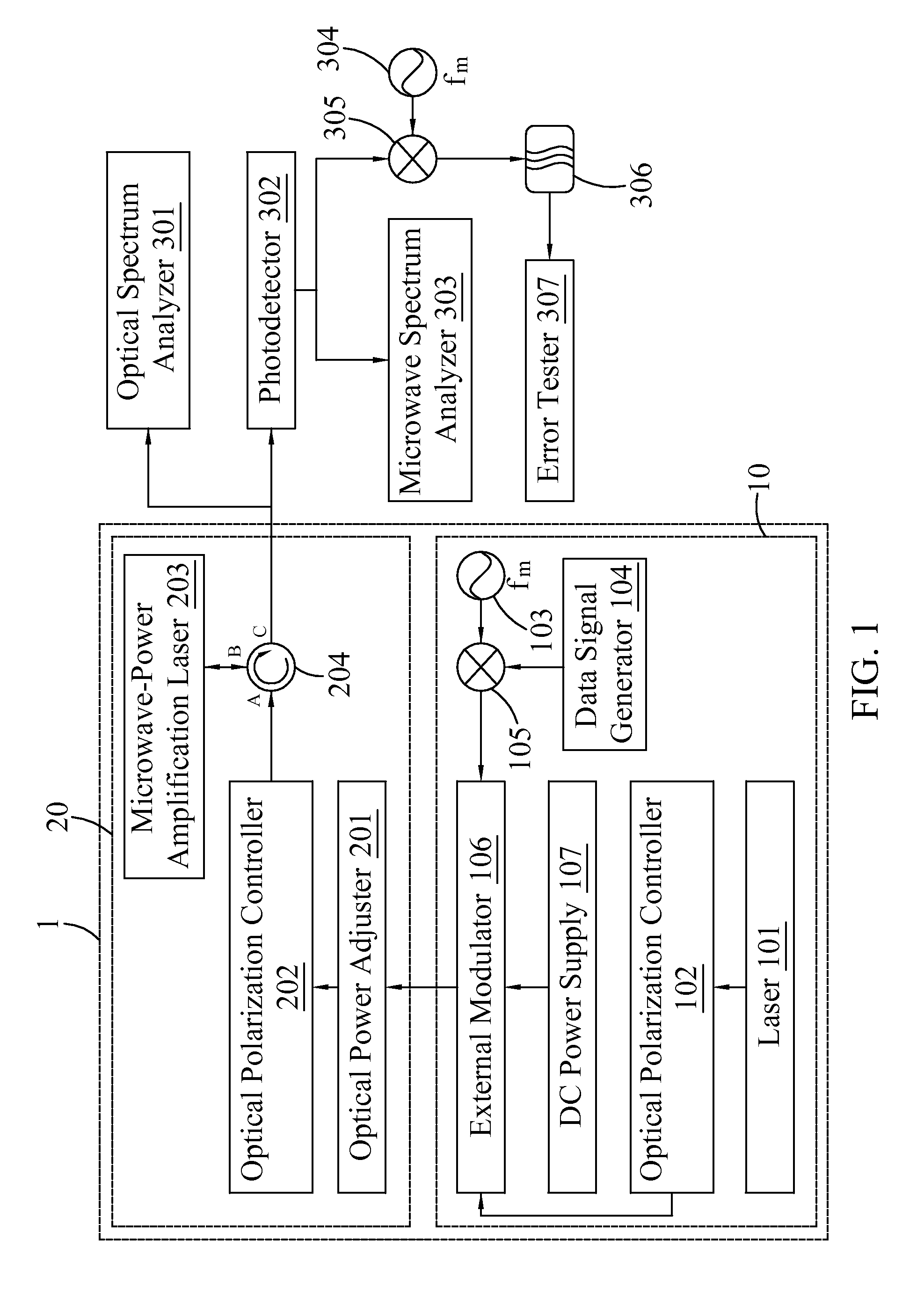

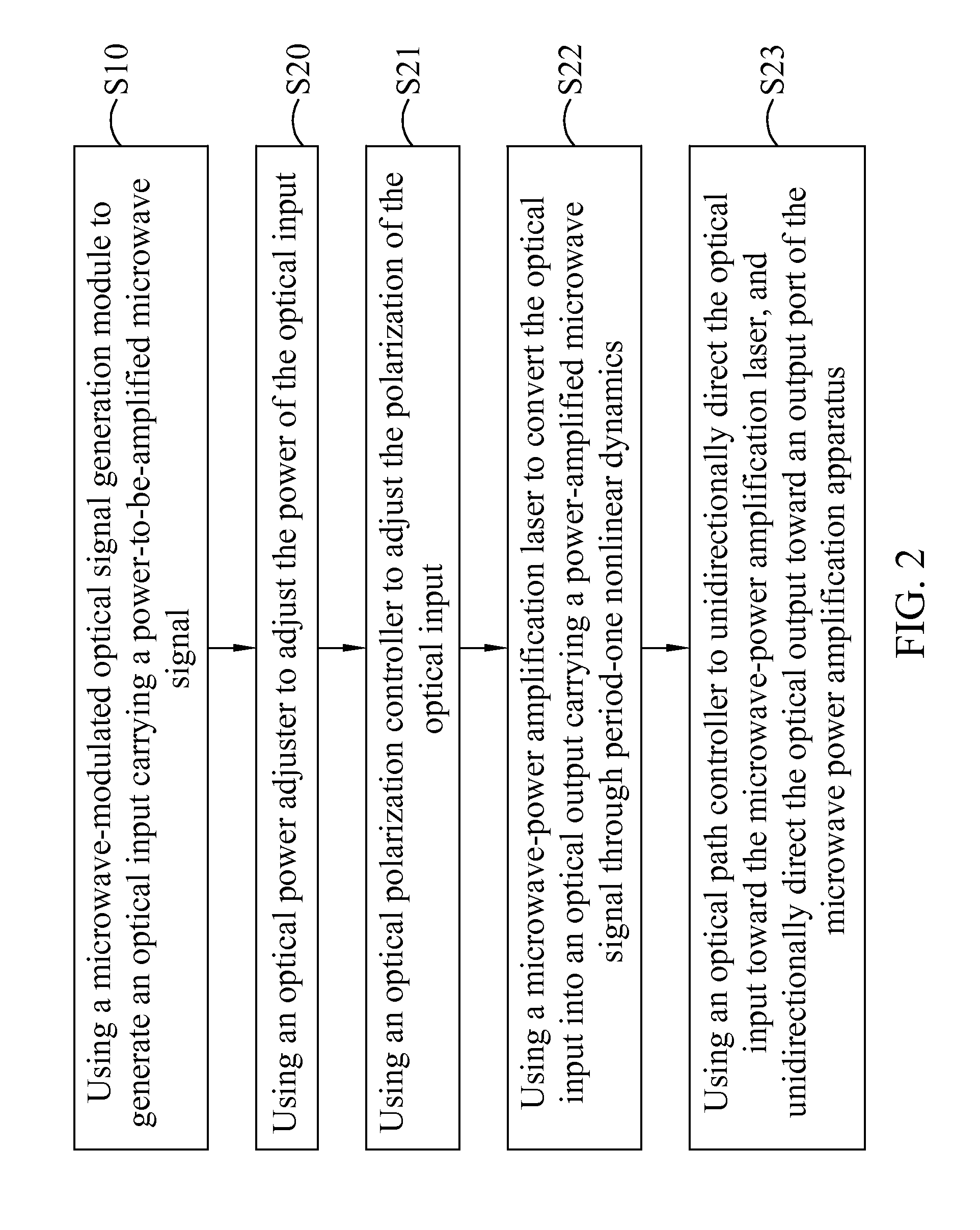

Microwave power amplification apparatus and method thereof

ActiveUS20150244331A1High detection sensitivityIncrease modulation depthPower amplifiersAmplifiers controlled by lightRadio over fiberSignal-to-noise ratio (imaging)

Period-one nonlinear dynamics of semiconductor lasers are utilized to provide an apparatus for photonic microwave power amplification in radio-over-fiber links through optical modulation depth improvement. The microwave power amplification apparatus includes a microwave-modulated optical signal generation module and a microwave power amplification module. The amplification capability of the present microwave power amplification apparatus covers a broad microwave range, from less than 25 GHz to more than 60 GHz, and a wide gain range, from less than 10 dB to more than 30 dB. The microwave phase quality is mainly preserved while the microwave power is largely amplified, improving the signal-to-noise ratio up to at least 25 dB. The bit-error ratio at 1.25 Gb / s is better than 10−9 and a sensitivity improvement of up to at least 15 dB is feasible.

Owner:NAT CHENG KUNG UNIV

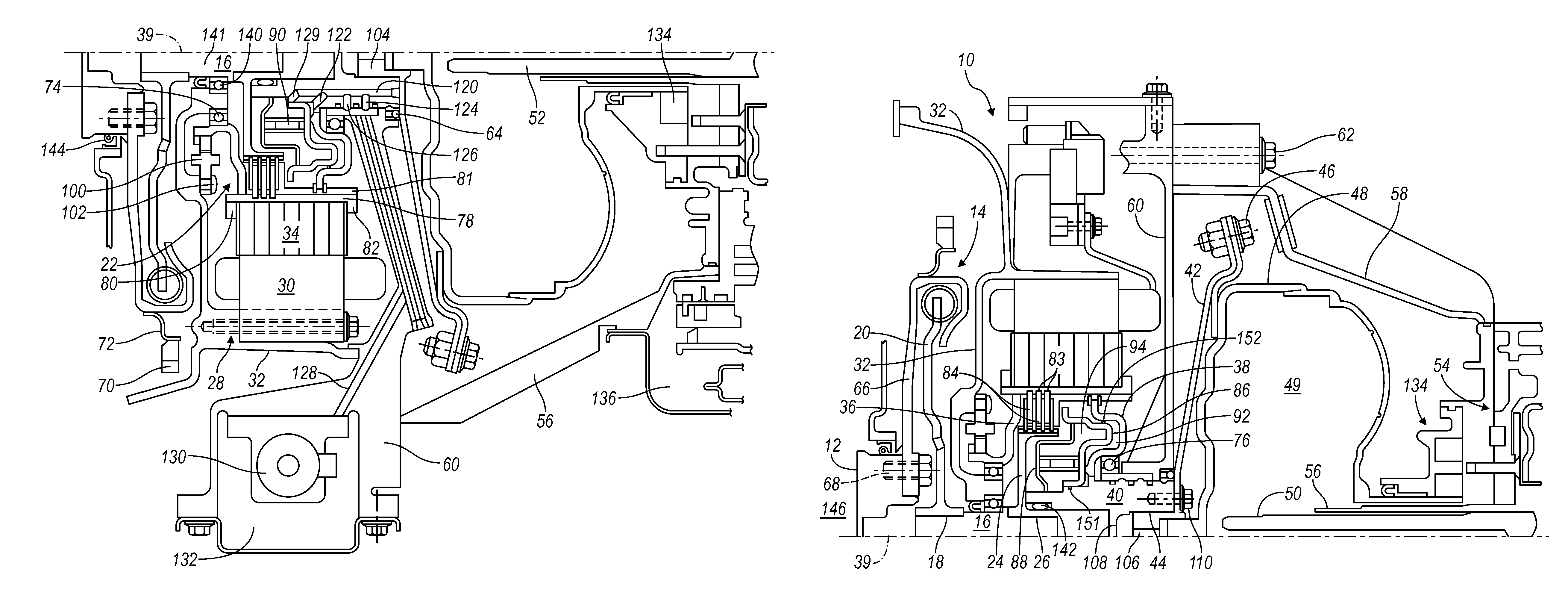

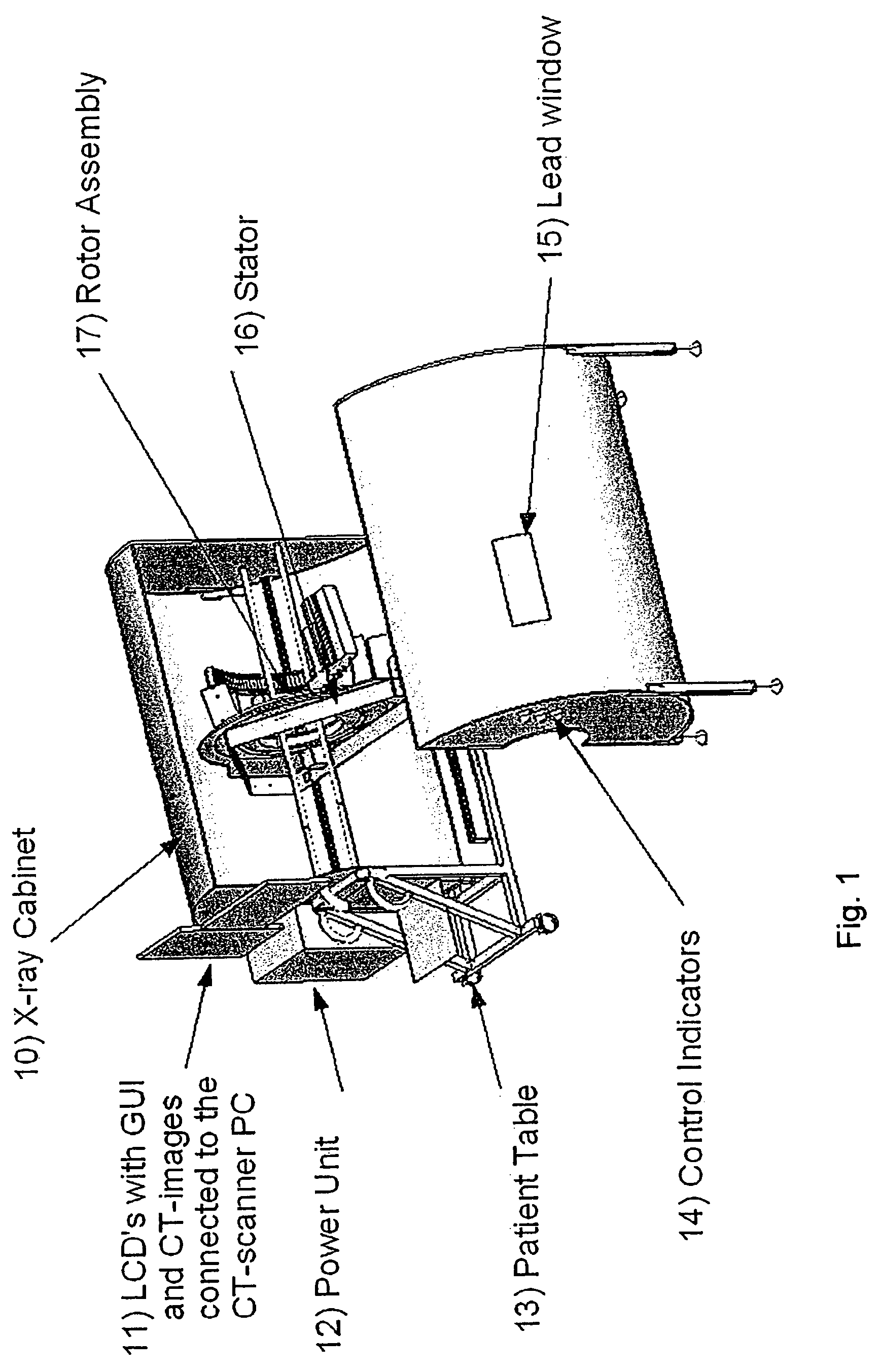

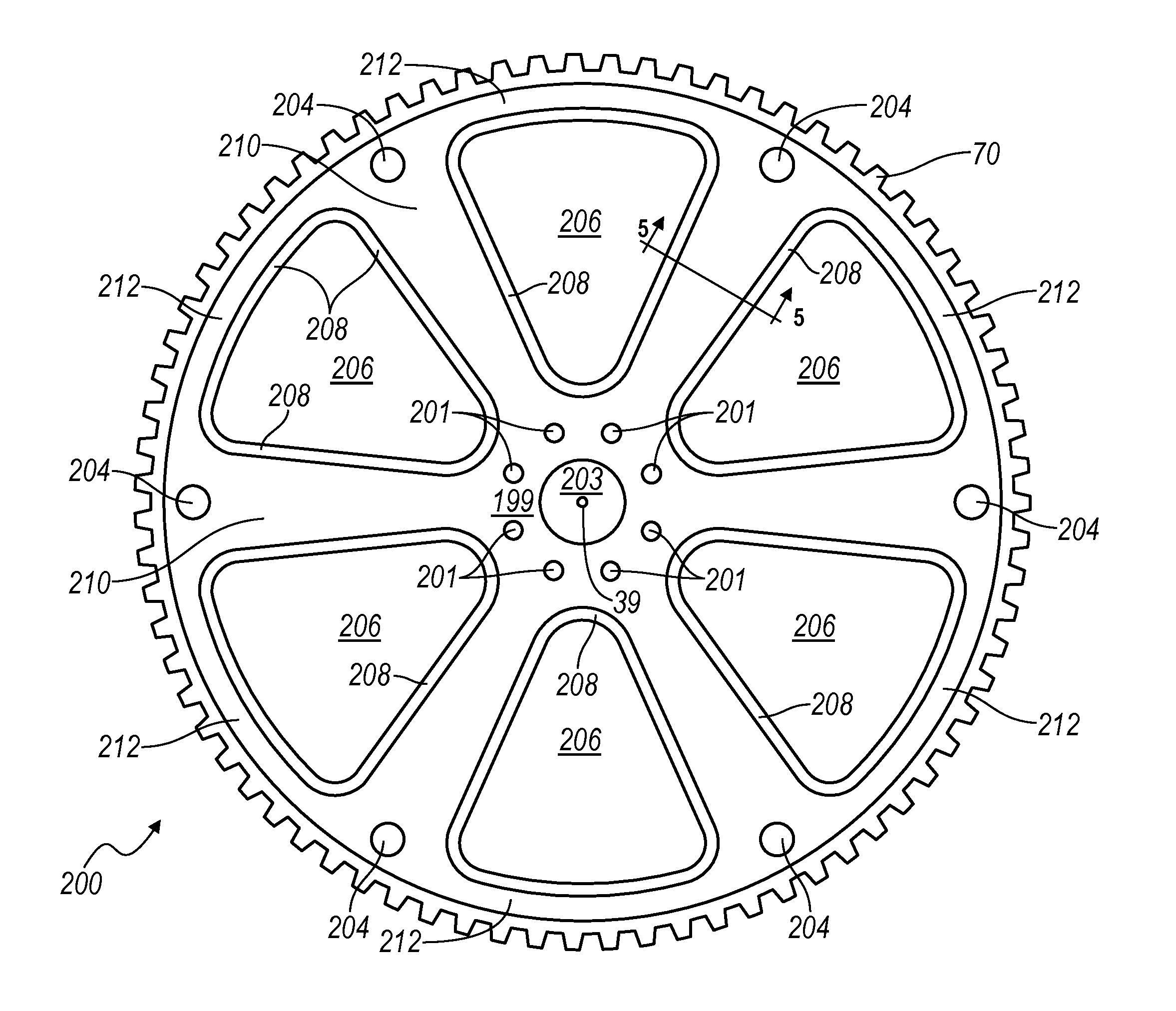

Dual drive plate damper for hybrid electric vehicles

ActiveUS20150114787A1Easy to installLow installationHybrid vehiclesYielding couplingEngineeringElectric vehicle

An assembly includes an engine output concentric with an axis, an input, a starting gear, a first drive plate secured to the engine output, including a rim supporting the starting gear, and arms extending radially outward from the axis, and a second drive plate rotatably secured to the input, and secured to the first drive plate at a location spaced radially outward from the axis.

Owner:FORD GLOBAL TECH LLC

CT scanning system

ActiveUS8540425B2Affordable price levelLow costX-ray tube vessels/containerRadiation diagnosticsComputed tomographyX-ray

A CT scanning system having a patient table and a gantry comprising an x-ray source configured to irradiate an x-ray beam while at least partly rotating about an object being arranged on the patient table in order to be scanned. The gantry comprises an x-ray detector configured to receive x-rays penetrating through the object to be scanned and is further configured to provide output signals representative of the received x-rays. The system further comprises an x-ray cabinet comprising x-ray shielding material. The x-ray cabinet fully surrounds the gantry and the patient table. The patient table is configured to be fully inserted in the x-ray cabinet. The x-ray cabinet has an end part with a patient opening allowing the introduction of a patient into the x-ray cabinet through said opening. The system comprises a closure part for providing an x-ray shielding closure of the patient opening at the first end part.

Owner:GNI CO LTD

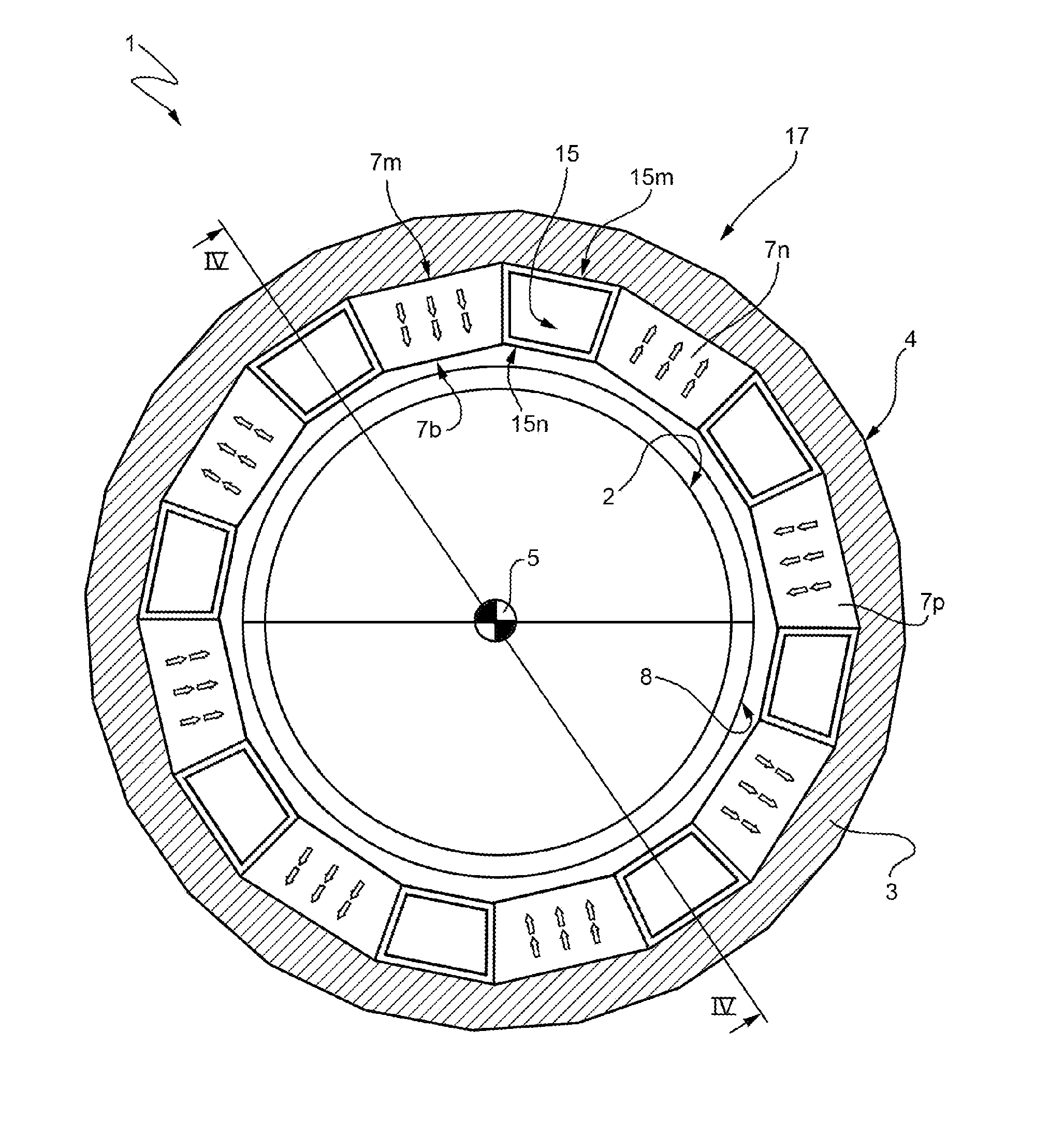

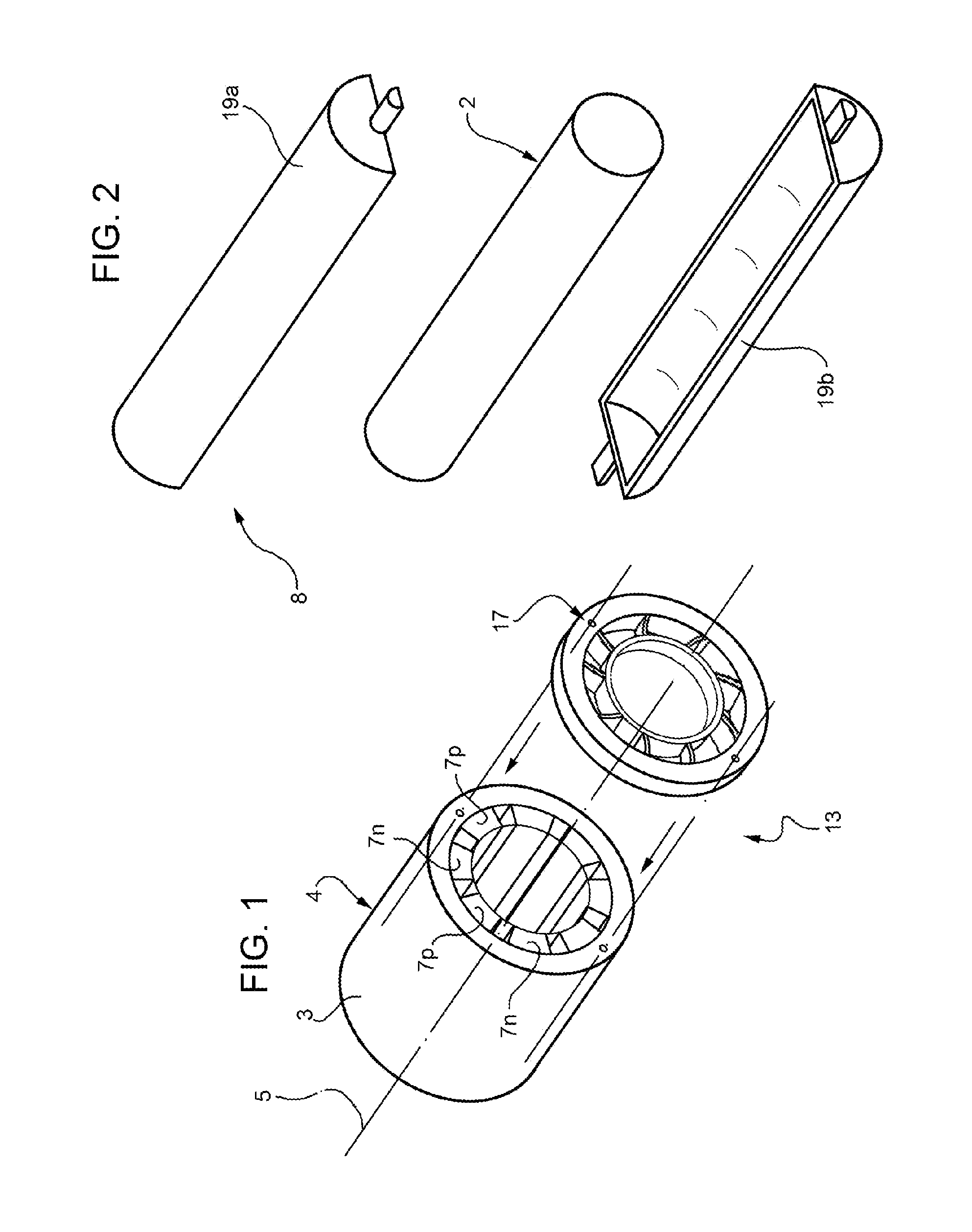

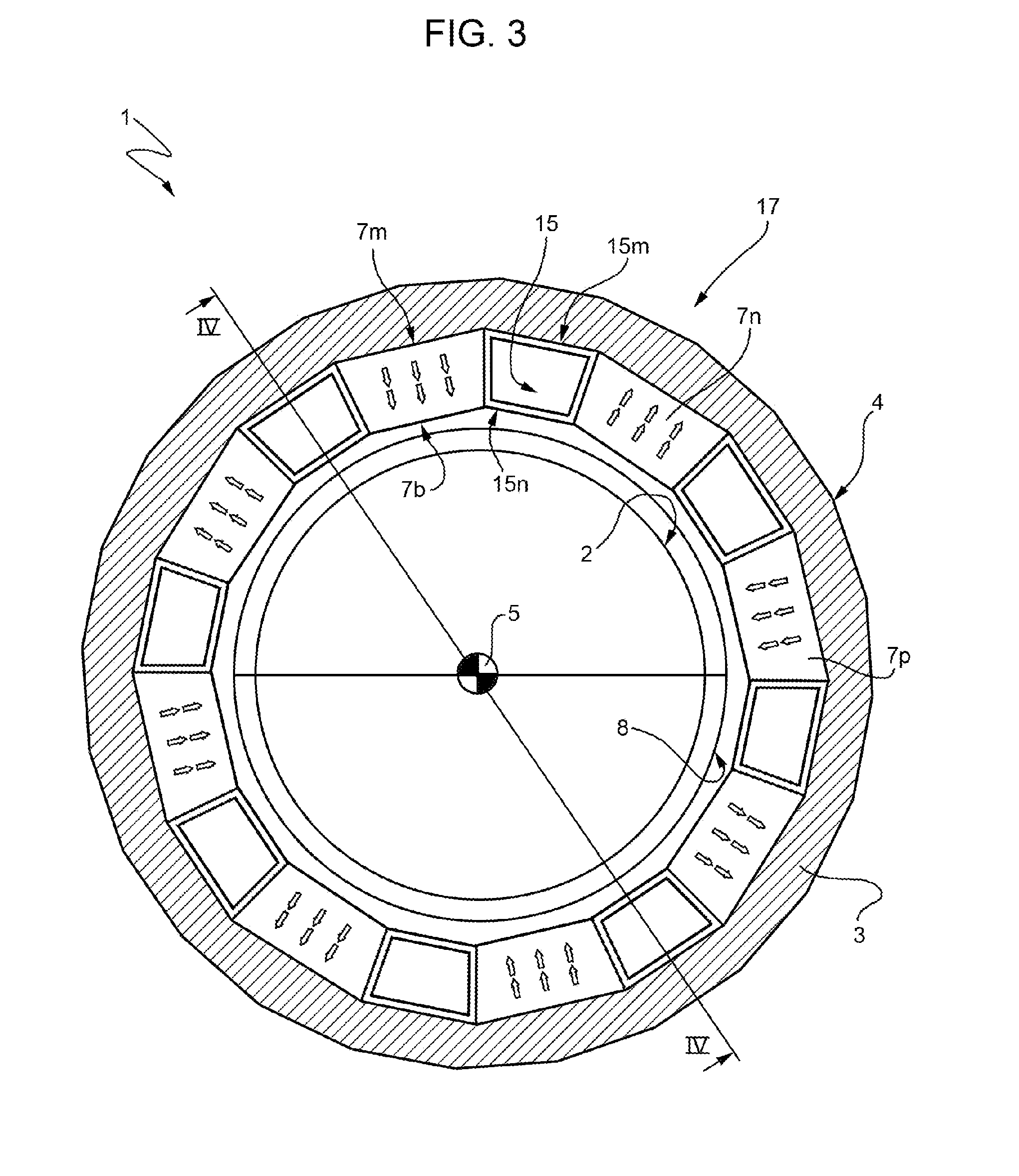

Device for induction heating of a billet

ActiveUS20150083713A1Small sizeImprove reliabilityCoil arrangementsInduction heating apparatusMetallic materialsEngineering

A device for the induction heating of a billet of metal of high electrical conductivity has: a tubular body supporting a plurality of permanent magnets arranged inside the tubular body, angularly spaced apart from each other and arranged so as to be alternated with opposite polarities. The device also has a support for the billet that is arranged inside the tubular body and faces the magnets, The device also has a motor adapted to rotate the tubular body with respect to the billet in order to induce currents in the billet that circulate within the metal material, obtaining the heating of the billet by the Joule effect. An integral cooling system for the permanent magnets is provided, this being carried by the tubular body and suitable for feeding cooling air flows between adjacent permanent magnets.

Owner:INOVA LAB

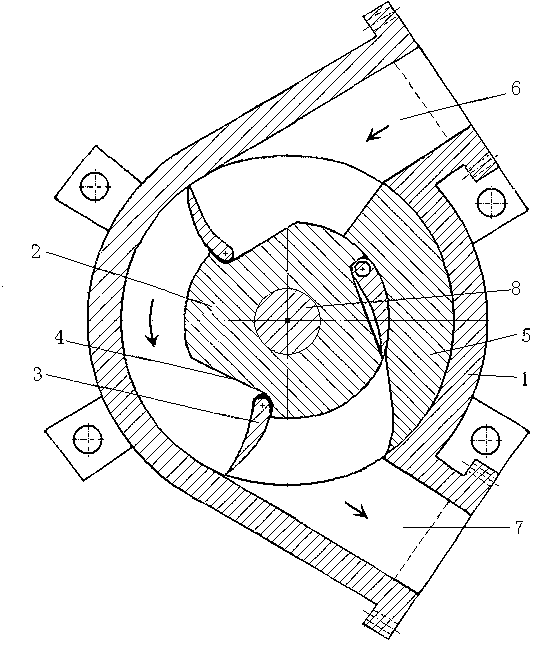

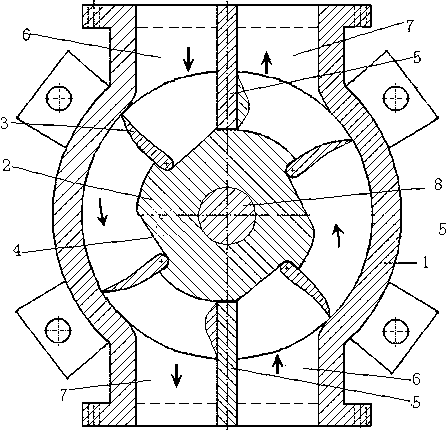

Flow-cutting channel type water turbine

ActiveCN103161645ASimple structureEasy to processFinal product manufactureHydro energy generationWater channelWater turbine

A flow-cutting channel type water turbine comprises a machine shell, a main shaft, a turning wheel, and a separation body. At least three pairs of vanes which are capable of being folded and unfolded are evenly arranged on the turning wheel. A water channel inside the water turbine is divided into one channel or more channels by the separation body. The water channel is perpendicular to a rotary shaft. A water inlet of the water channel is connected with a high-pressure water conduit. A water outlet of the water channel is connected with an exhaust water pipe. A vane chamber is arranged on each vane. A limiting portion capable of being unfolded by a certain degree is arranged on the vane chamber. The direction of high-pressure water flowing into the water channel is perpendicular to the direction of the front side of the vane when the vane is unfolded. Speed and direction of the water are the same as those of each vane and the turning wheel is pushed to rotate. Water power is efficiently converted into mechanical power by the vanes. A slope sliding block is arranged on one lateral side, with low water pressure, of the separation body, wherein the slope sliding block is capable of guiding the vanes to be folded and then enabling the vanes to enter the vane chambers of the vanes. The vanes are automatically unfolded through a spring at the position of an inlet of high-pressure water after passing through the separation body in a rotating mode. The flow-cutting channel type water turbine has the advantages of being high in efficiency, simple in structure, easy to machine and manufacture, and easy to popularize.

Owner:宜昌光源电业有限责任公司

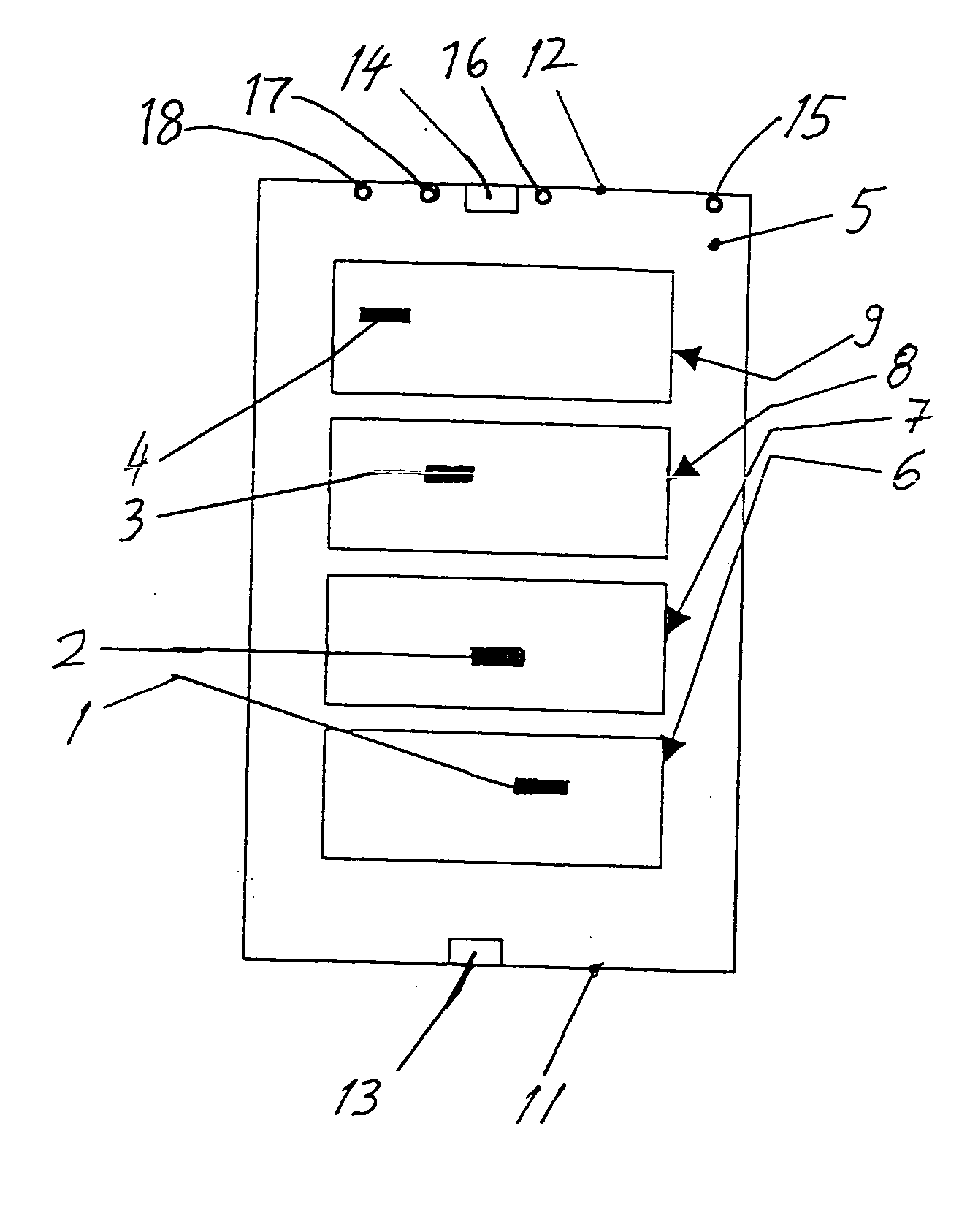

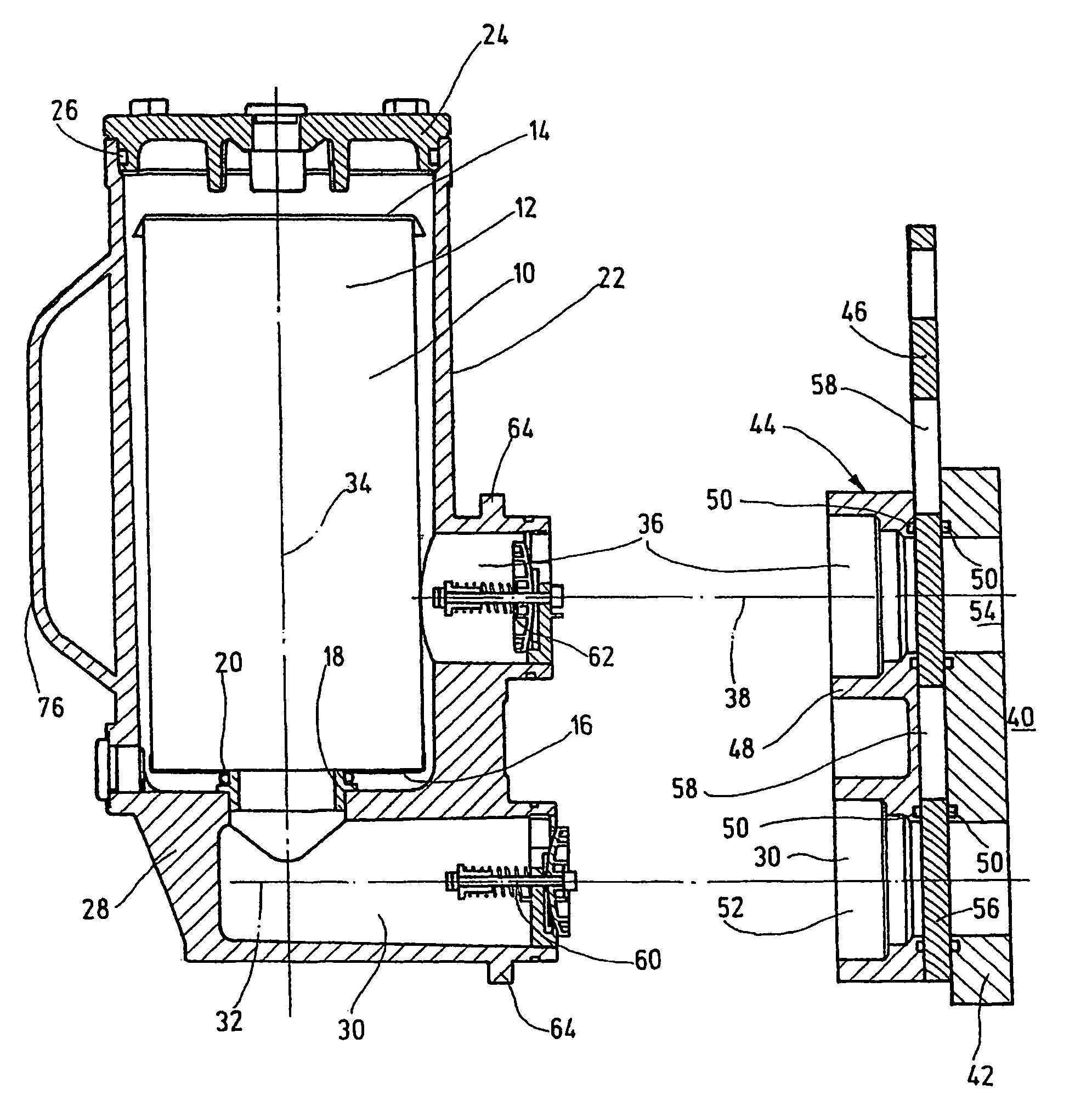

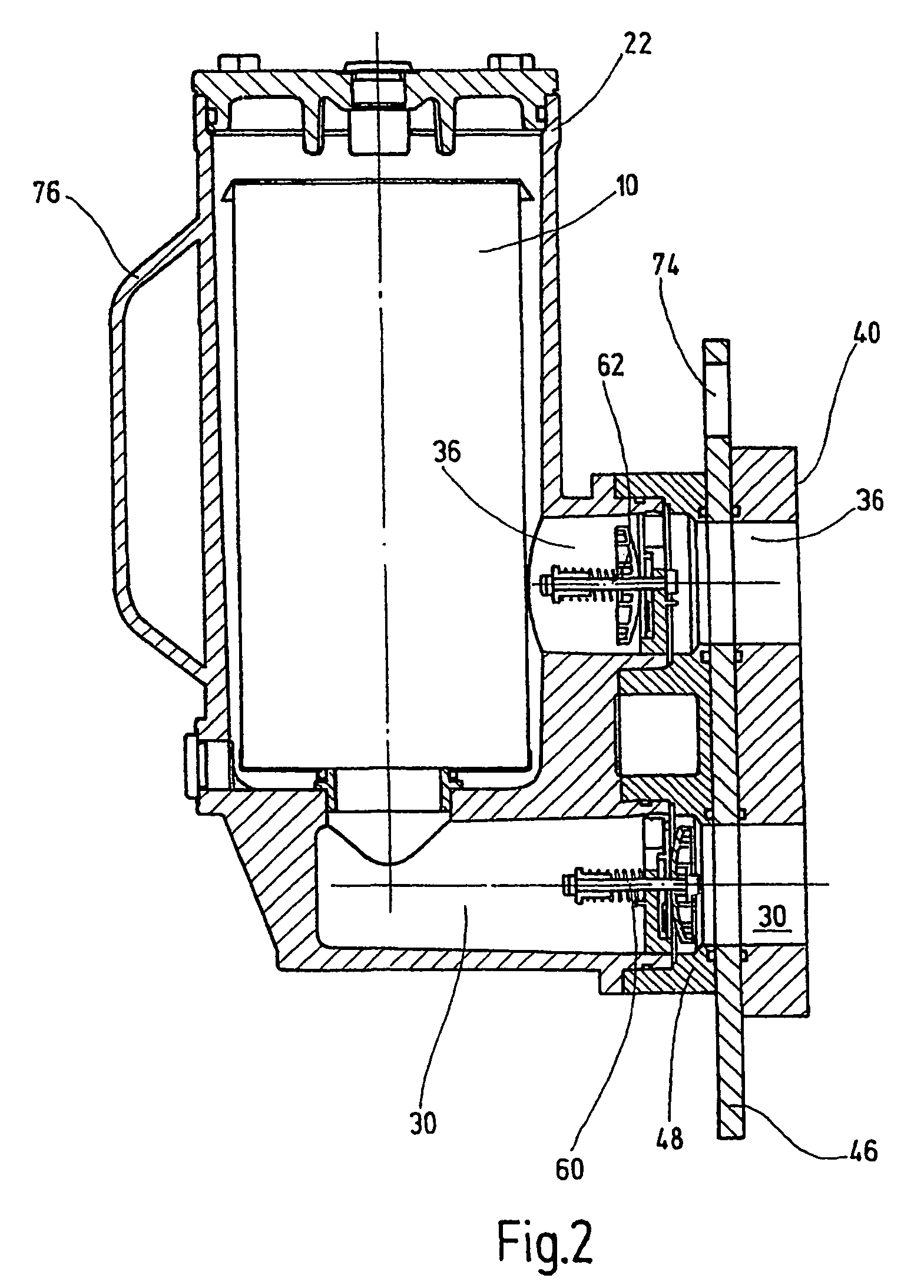

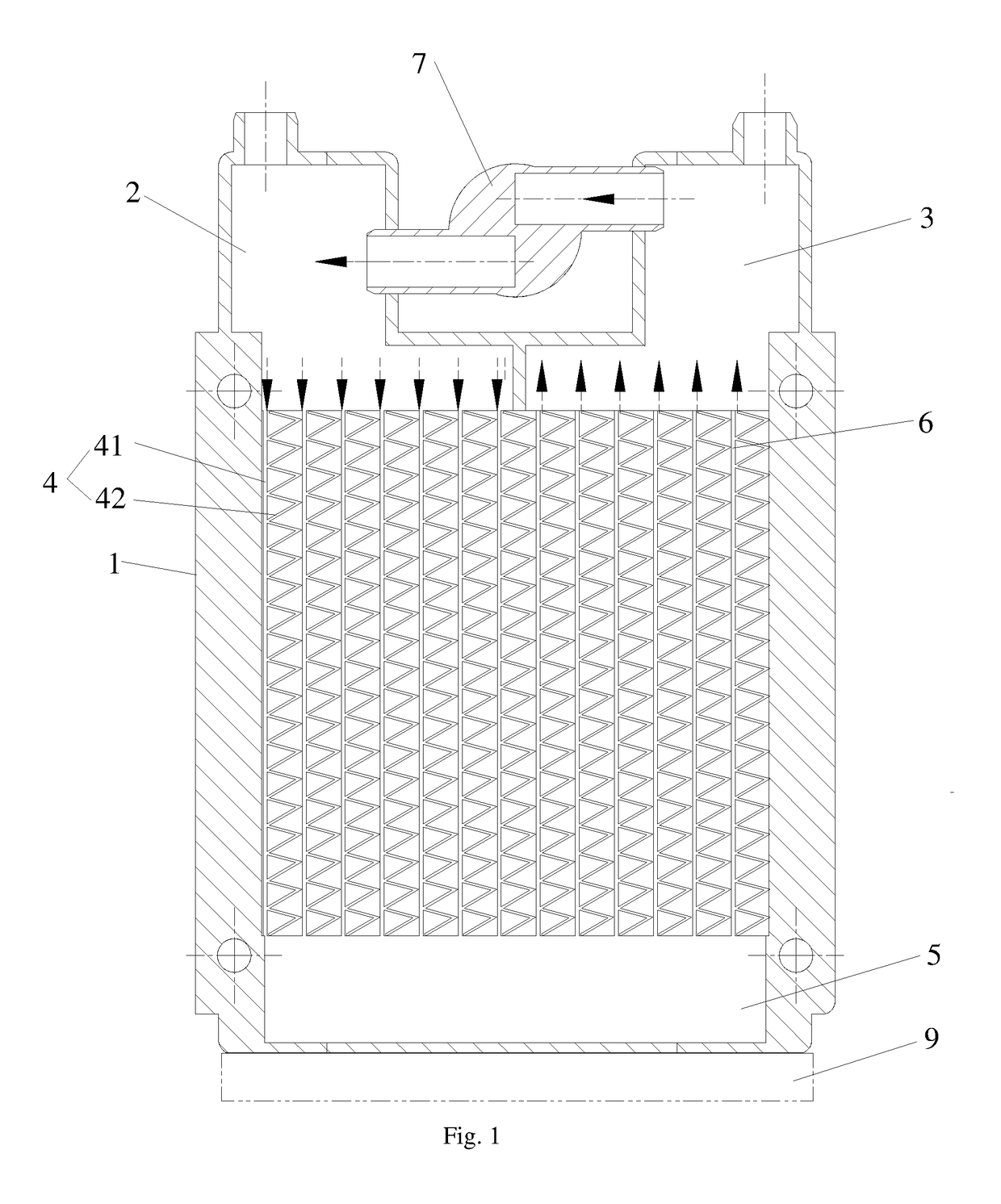

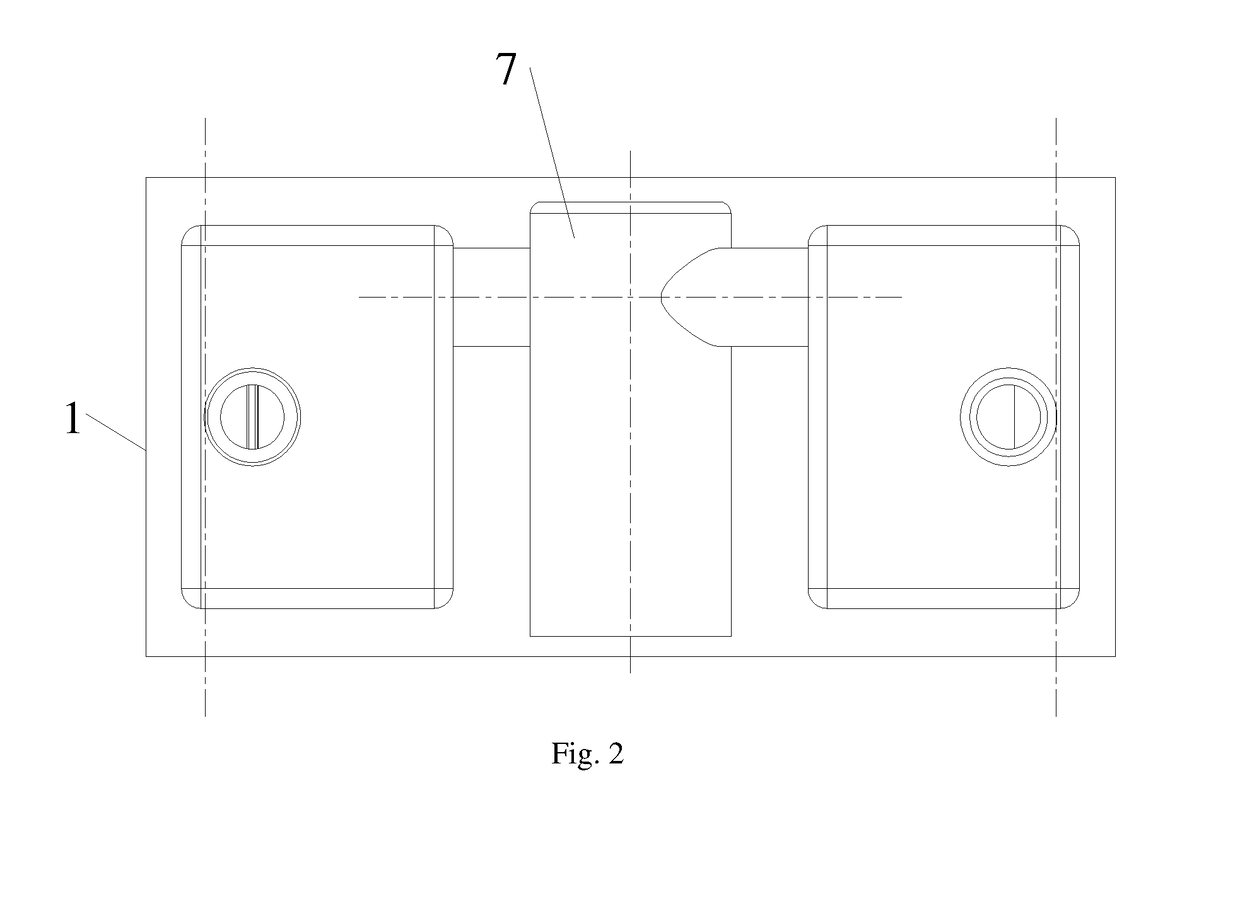

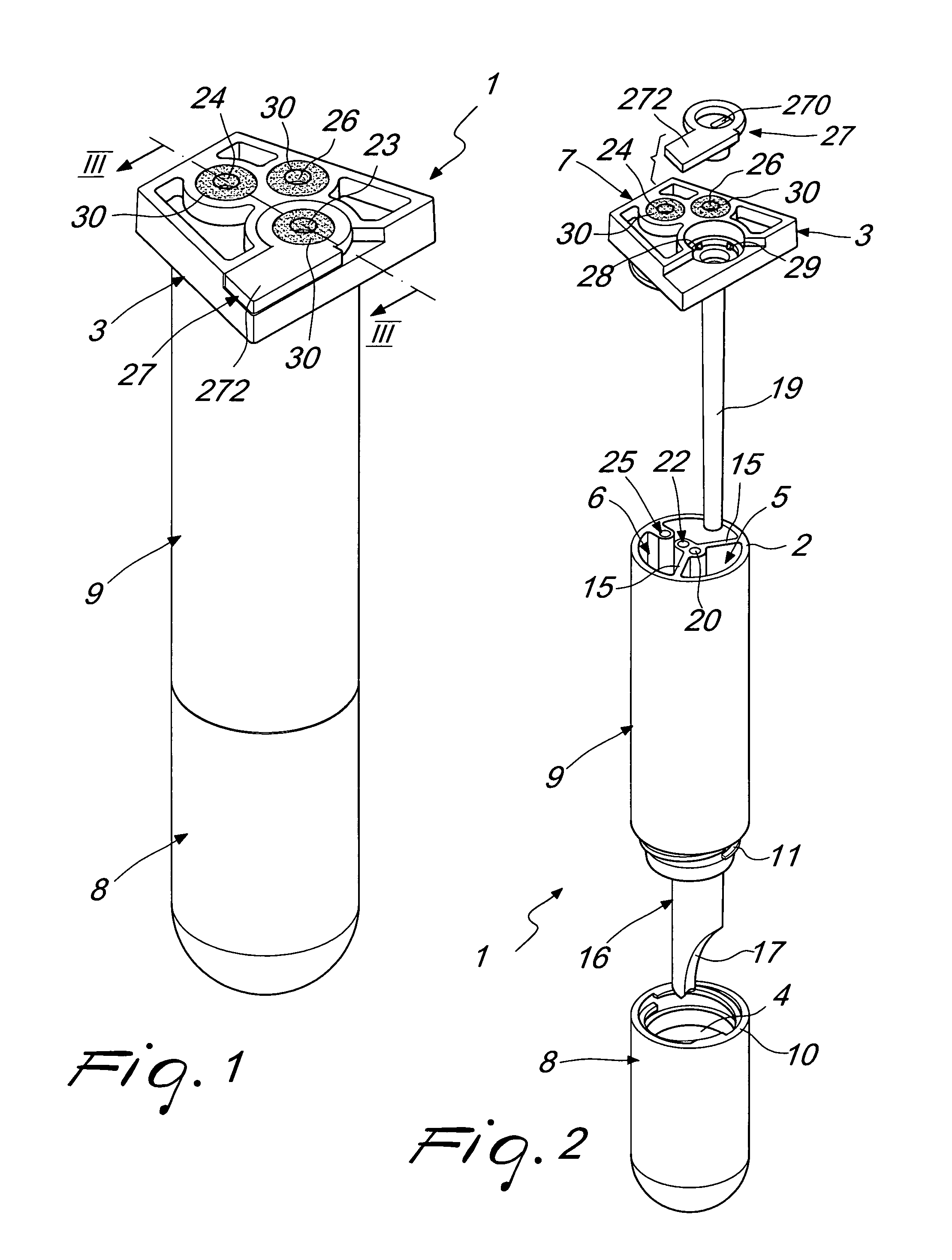

Filter device

ActiveUS7815054B2Low installationLow maintenanceSettling tanks feed/dischargeMembrane filtersFilter mediaEngineering

A filter device includes at least one filter element (10) housed in a filter housing (22) and connected for the flow of fluid by fluid connections (30, 36) to a fluid device, in particular in the form of a hydraulic tank (40), using a connector device (44). A plunger valve arrangement is achieved, whereby the connector device (44) is provided with at least one longitudinally-displaceable blocking piece (46). In the blocking position, the blocking piece blocks the provided fluid connections (30, 36). After displacement into an open position, it releases the fluid connections. A blocking or releasing of the fluid connections in a rapid operation process is permitted to carry out a filter element exchange for the used filter medium.

Owner:HYDAC FILTERTECHNIK GMBH

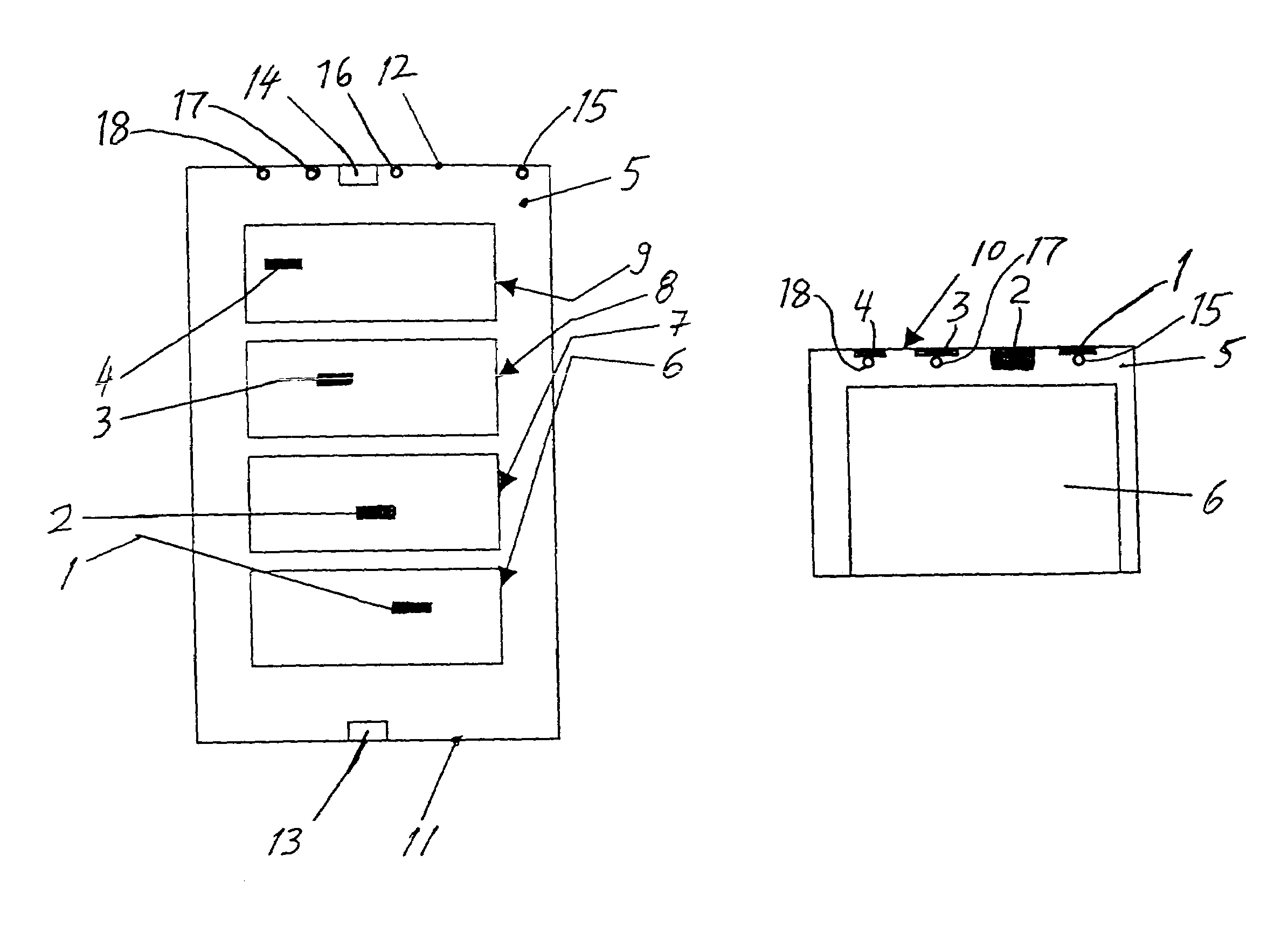

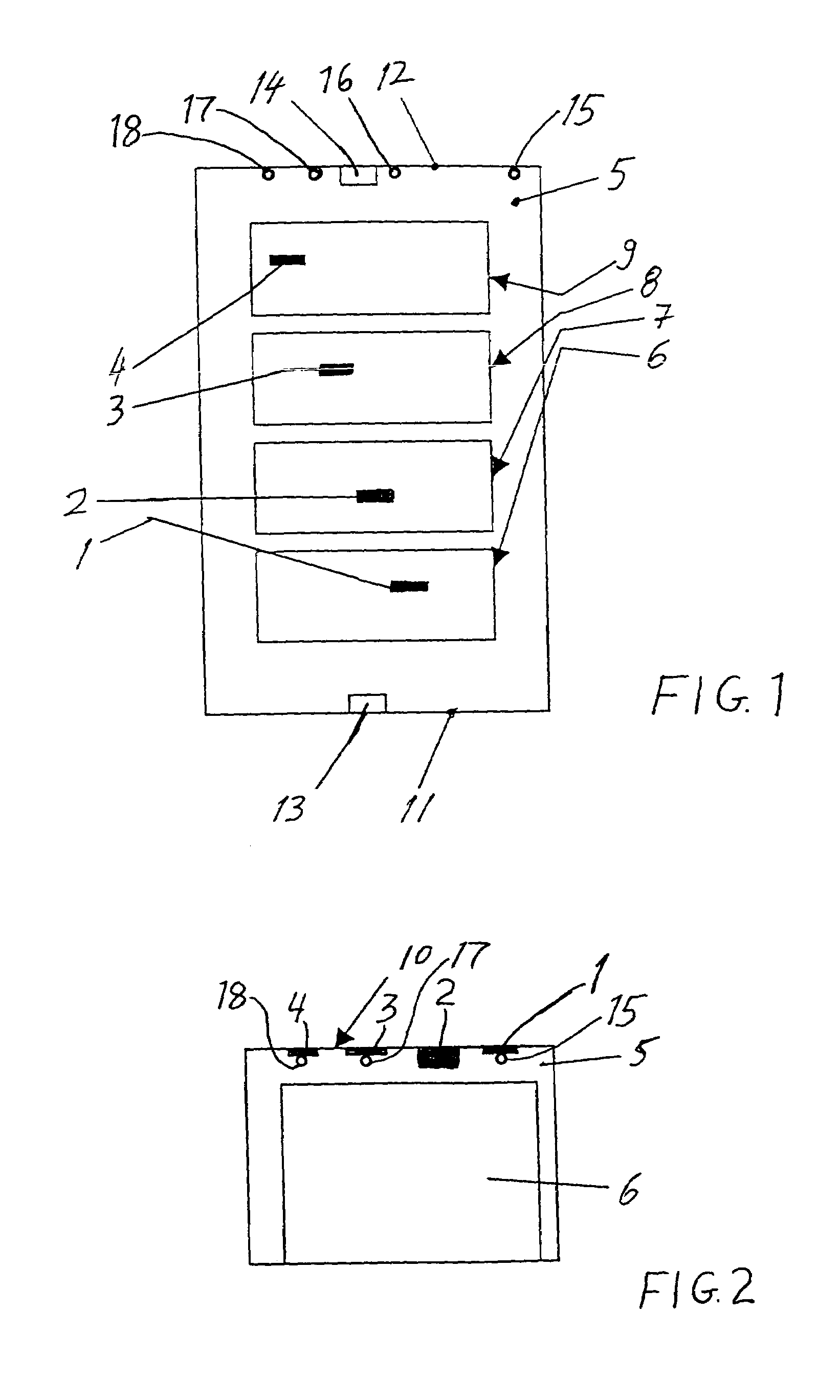

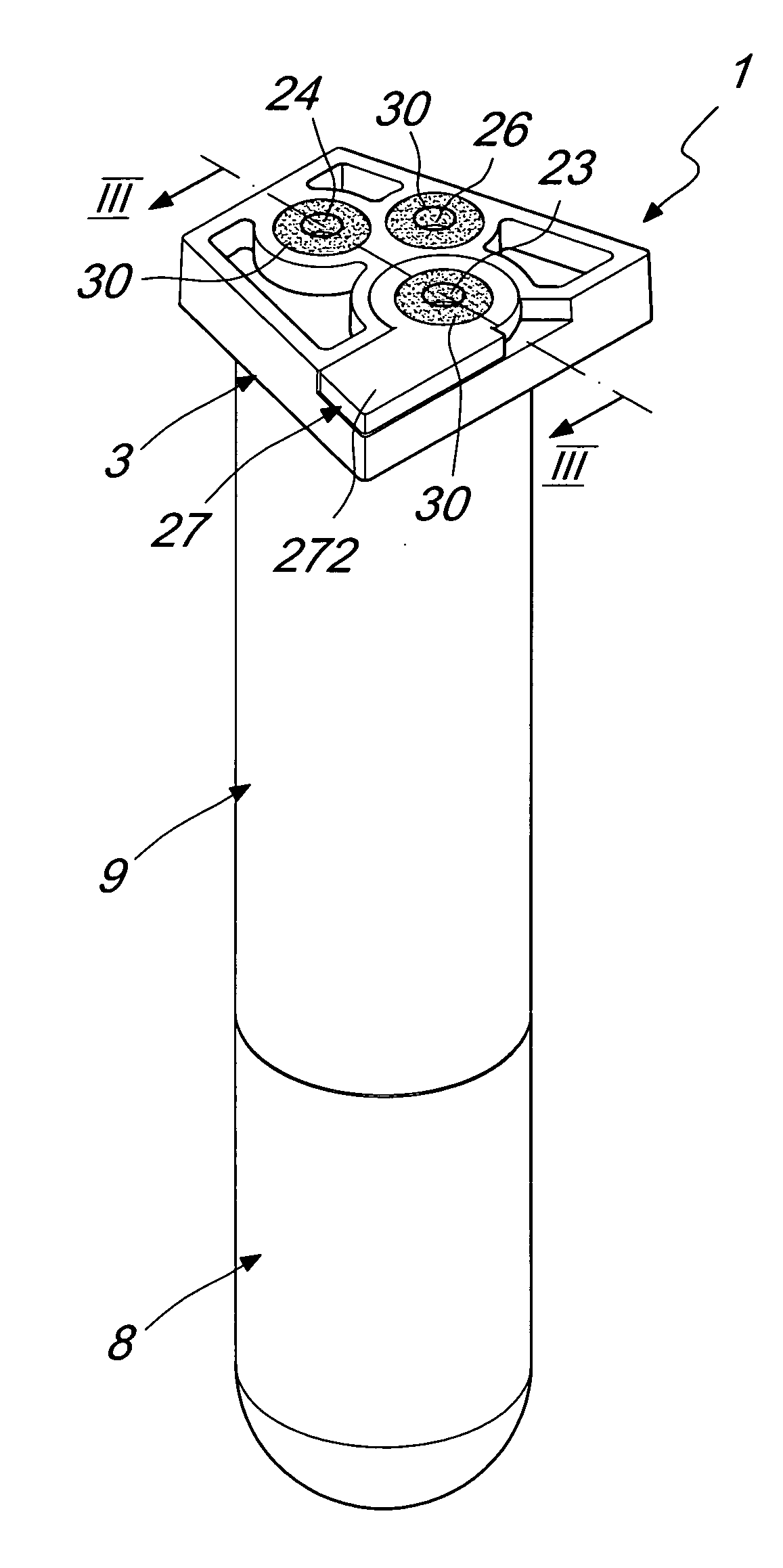

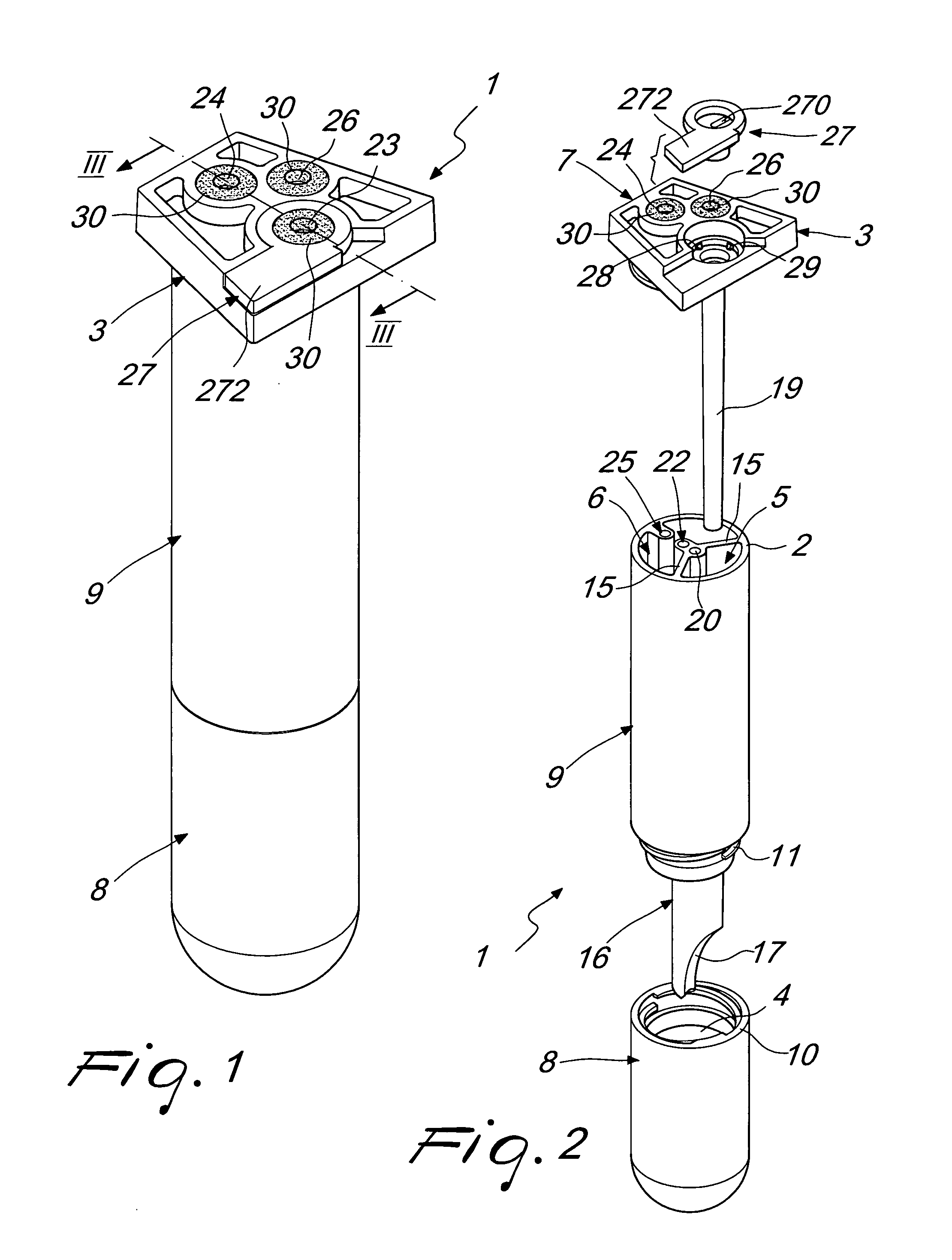

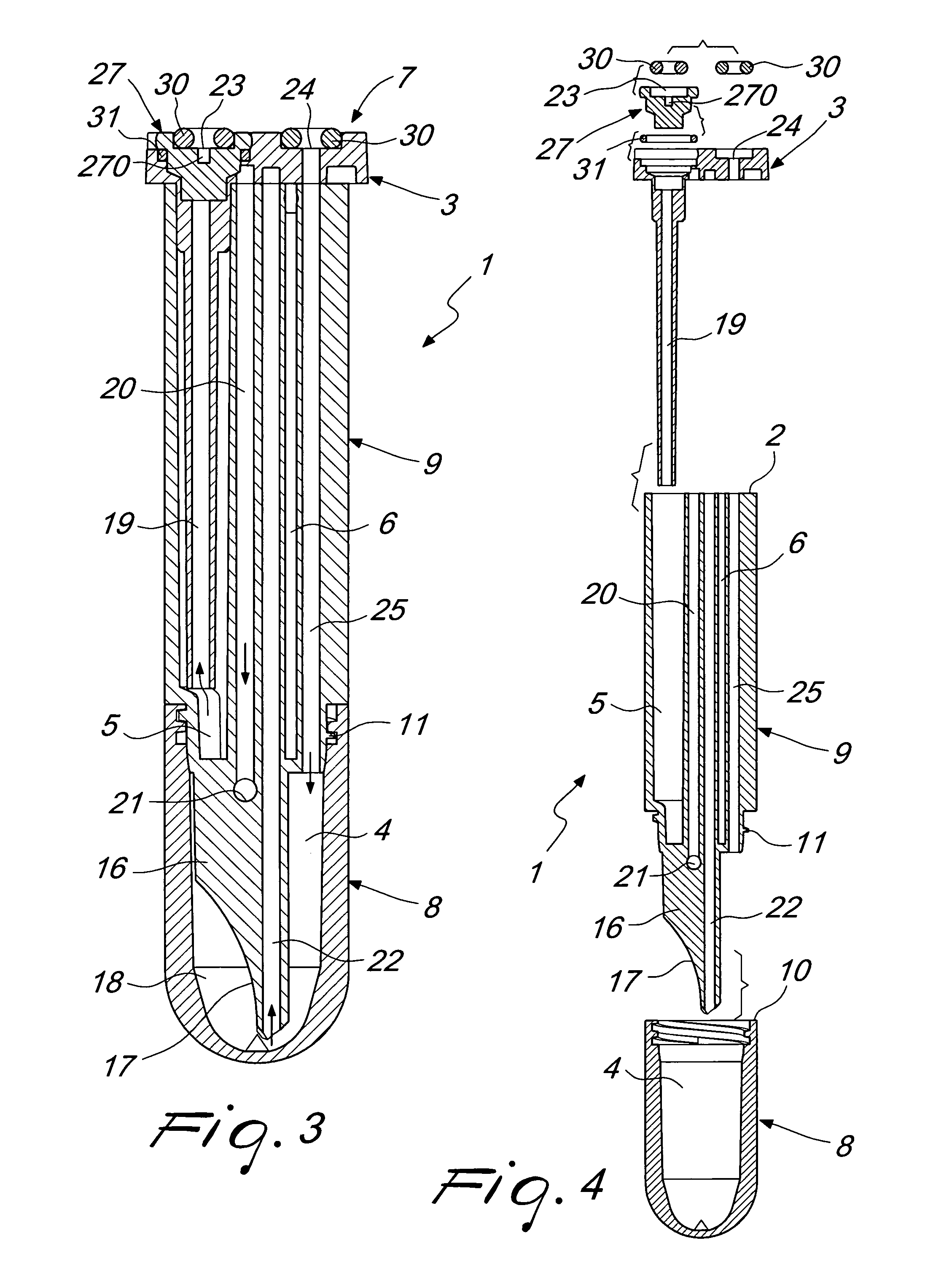

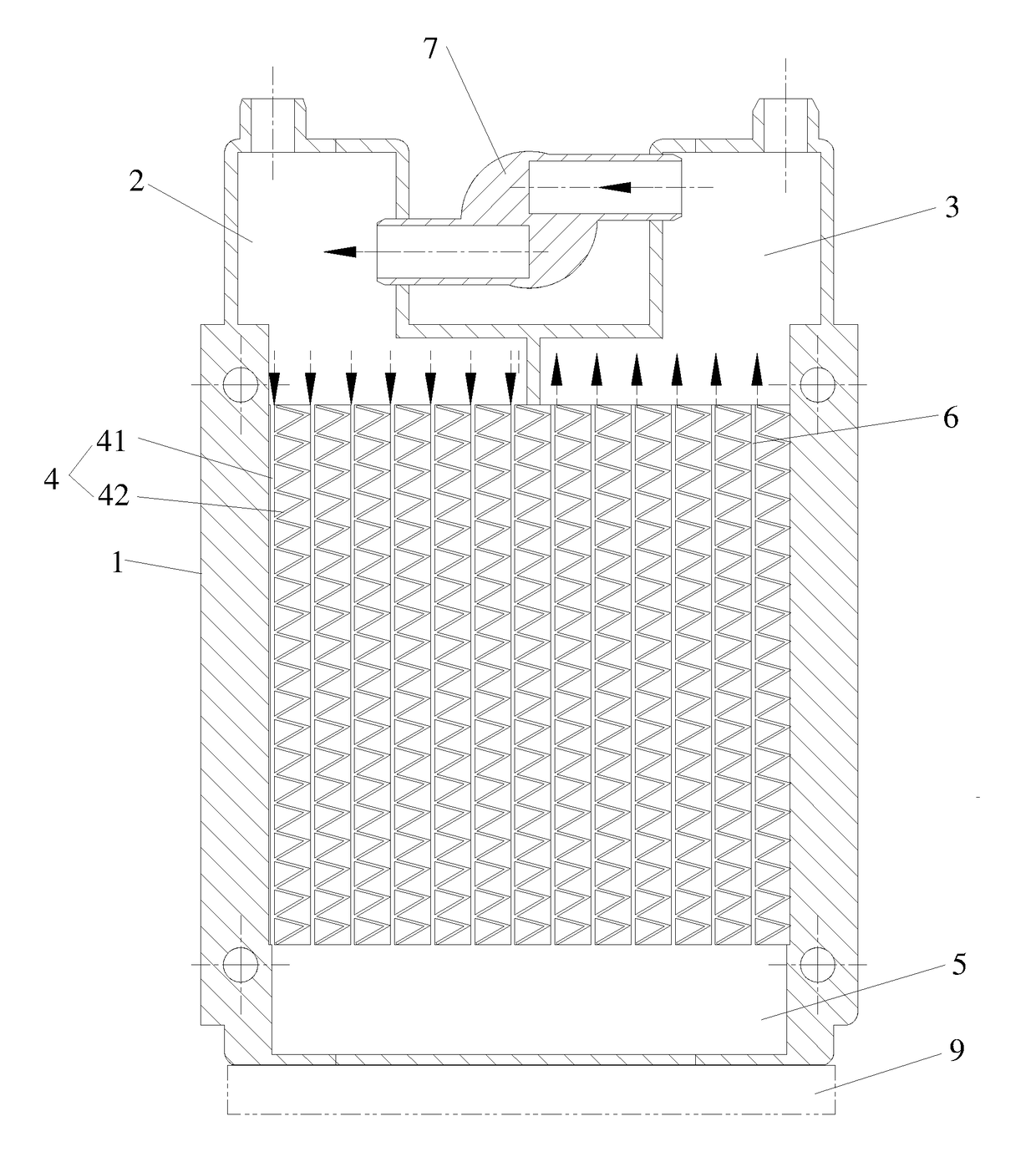

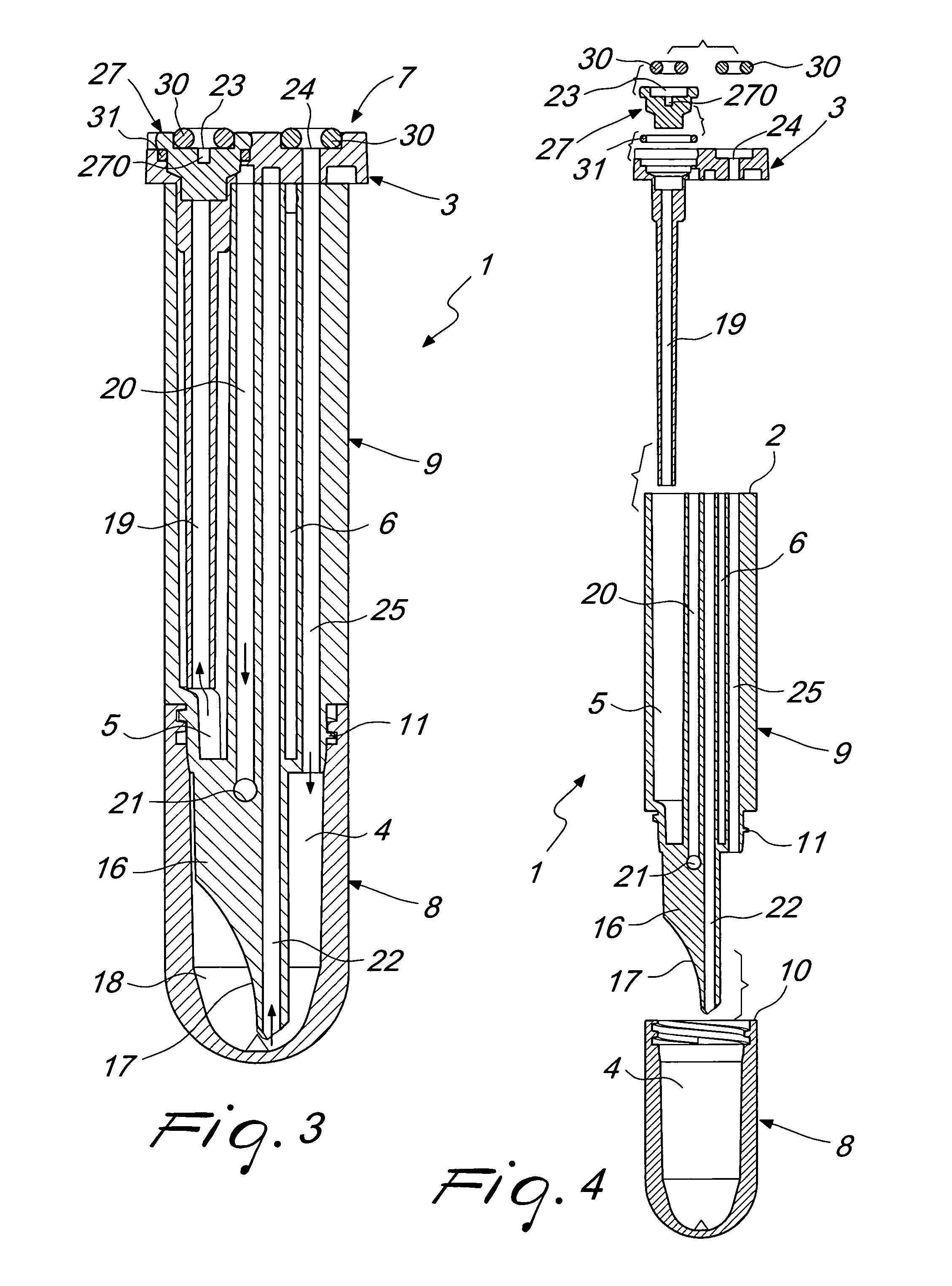

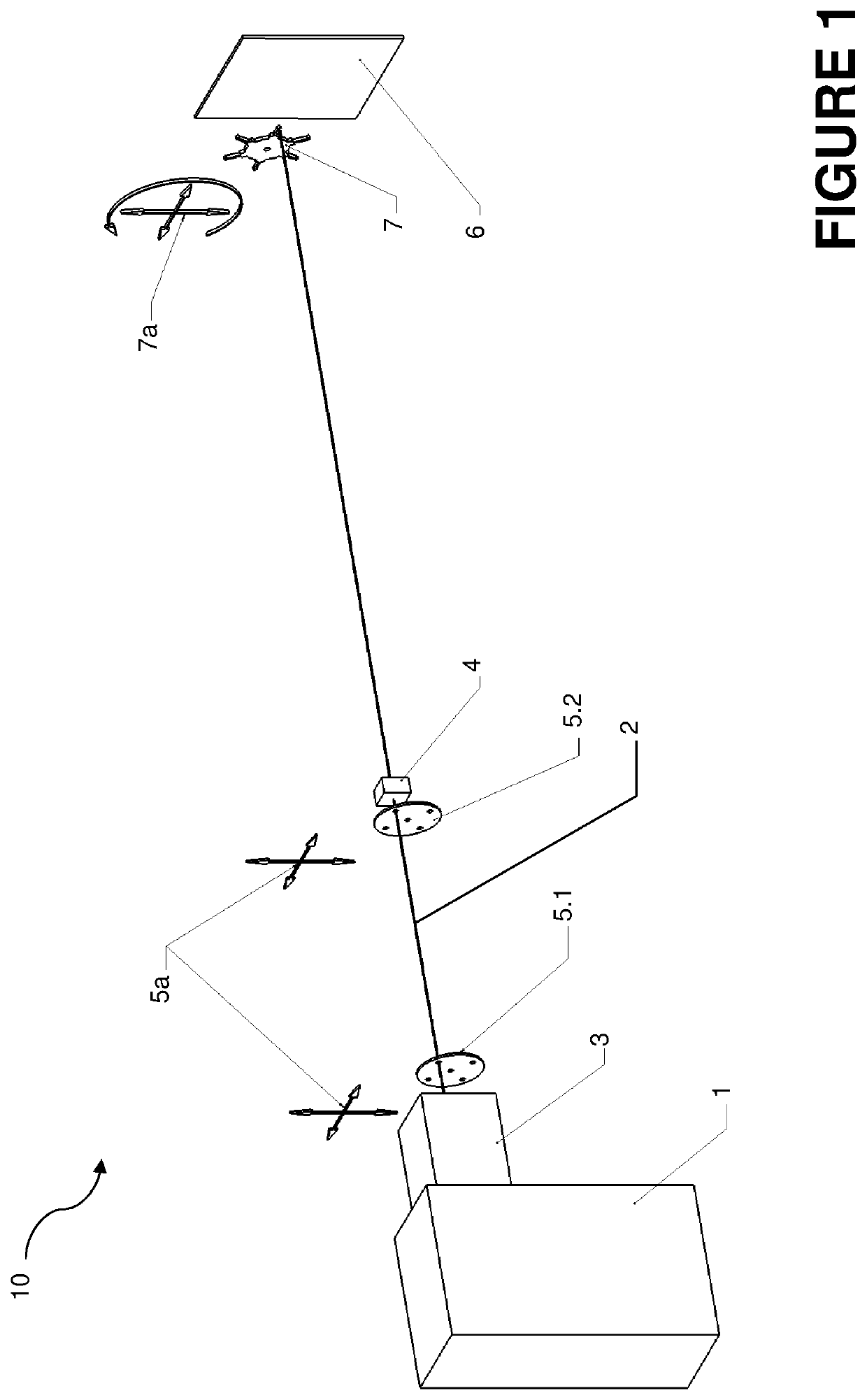

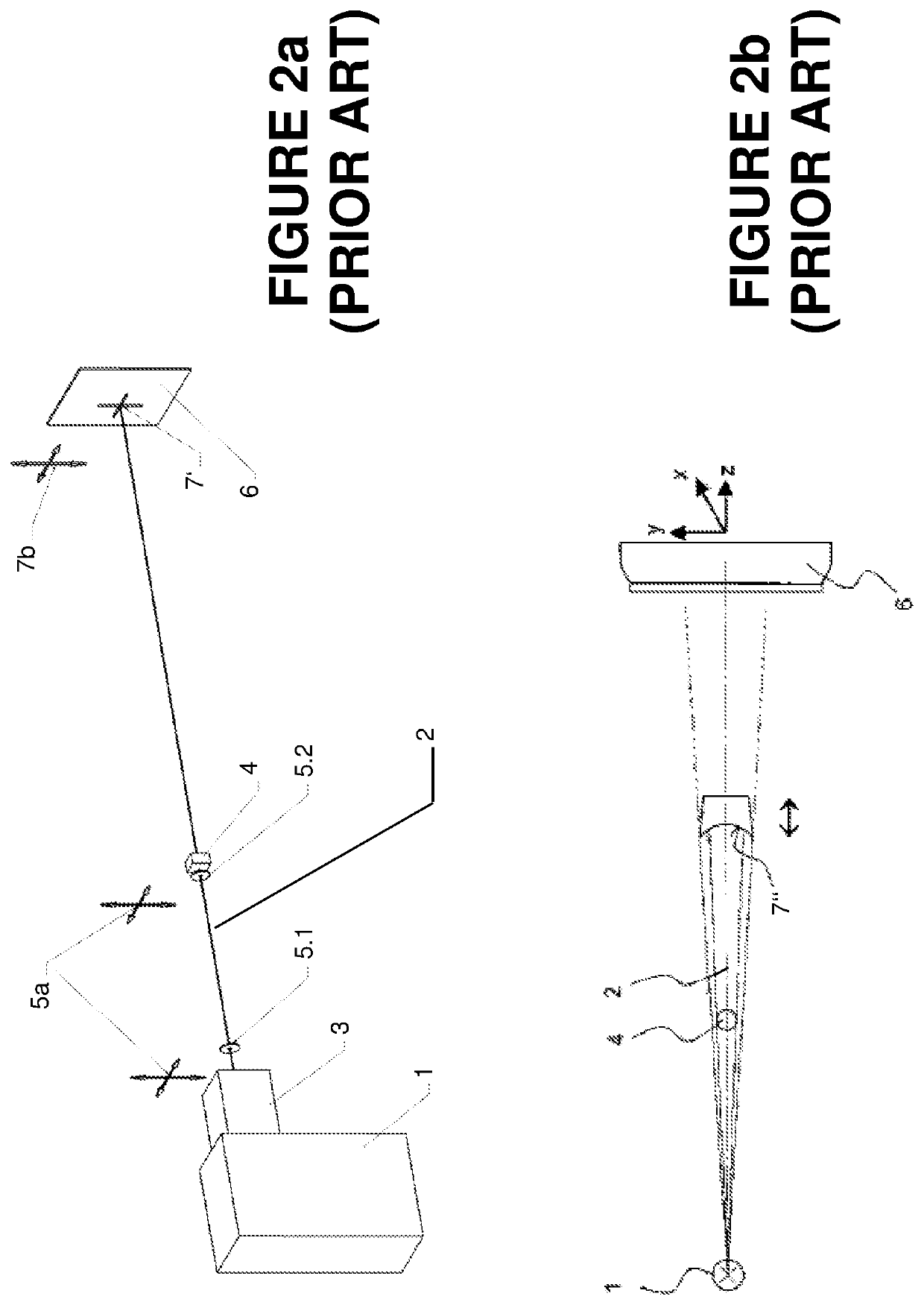

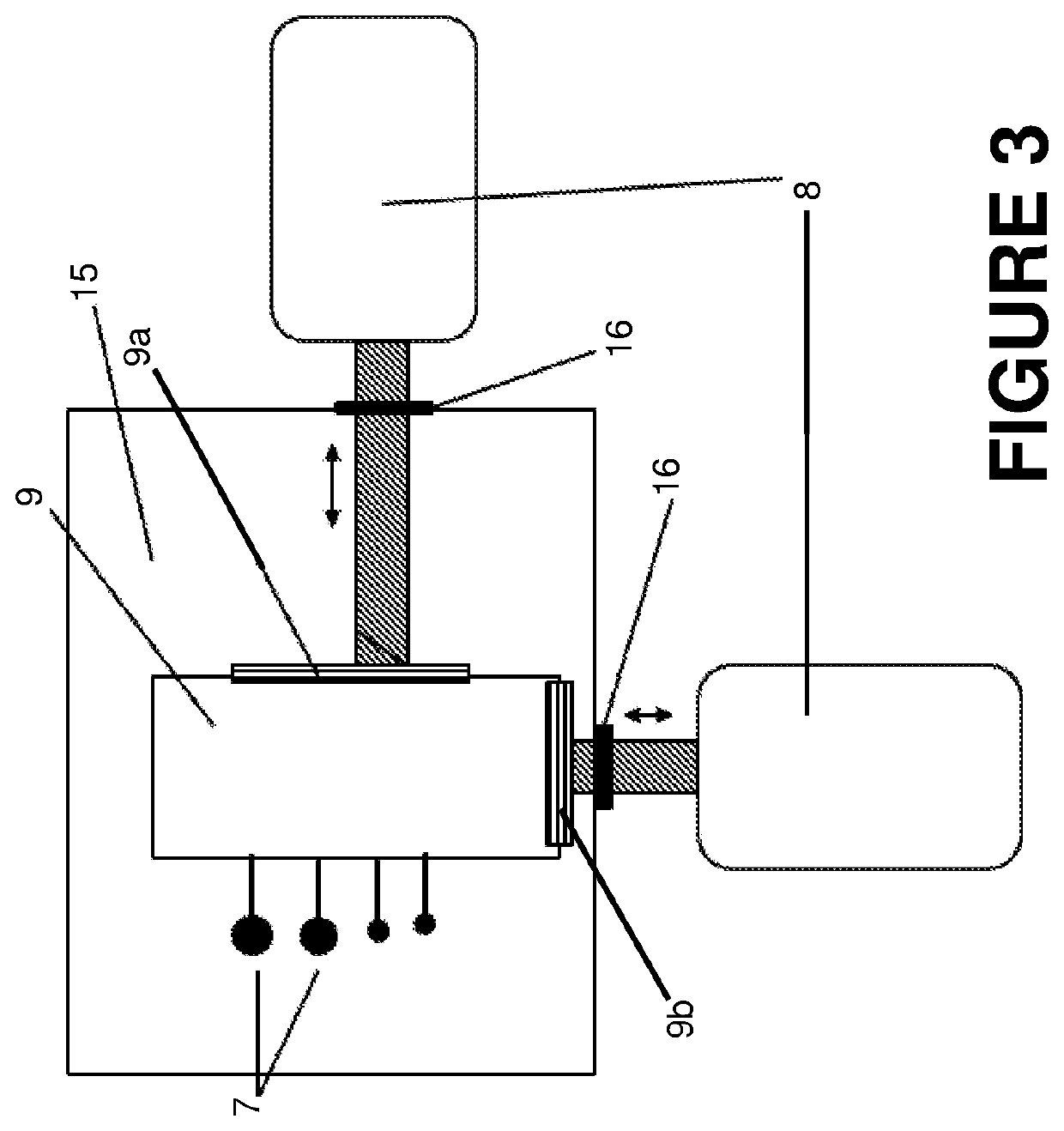

Reactor for performing biochemical processes

InactiveUS20100055698A1Easy to implementOvercomes drawbackBioreactor/fermenter combinationsBiological substance pretreatmentsProcedure AgentsBiochemical engineering

A reactor (1) for performing biochemical processes, particularly for extraction, purification, enrichment, sedimentation, comprising a container which is provided with at least one mouth (2) which is associated with closure means (3) of the removable type, the container having internally at least one process compartment (4), adapted to accommodate a sample of biochemical material to be processed, at least one containment chamber (5) for a process agent, and at least first means for transferring the process agent from the containment chamber to the process compartment.

Owner:SMART HOSPITAL +2

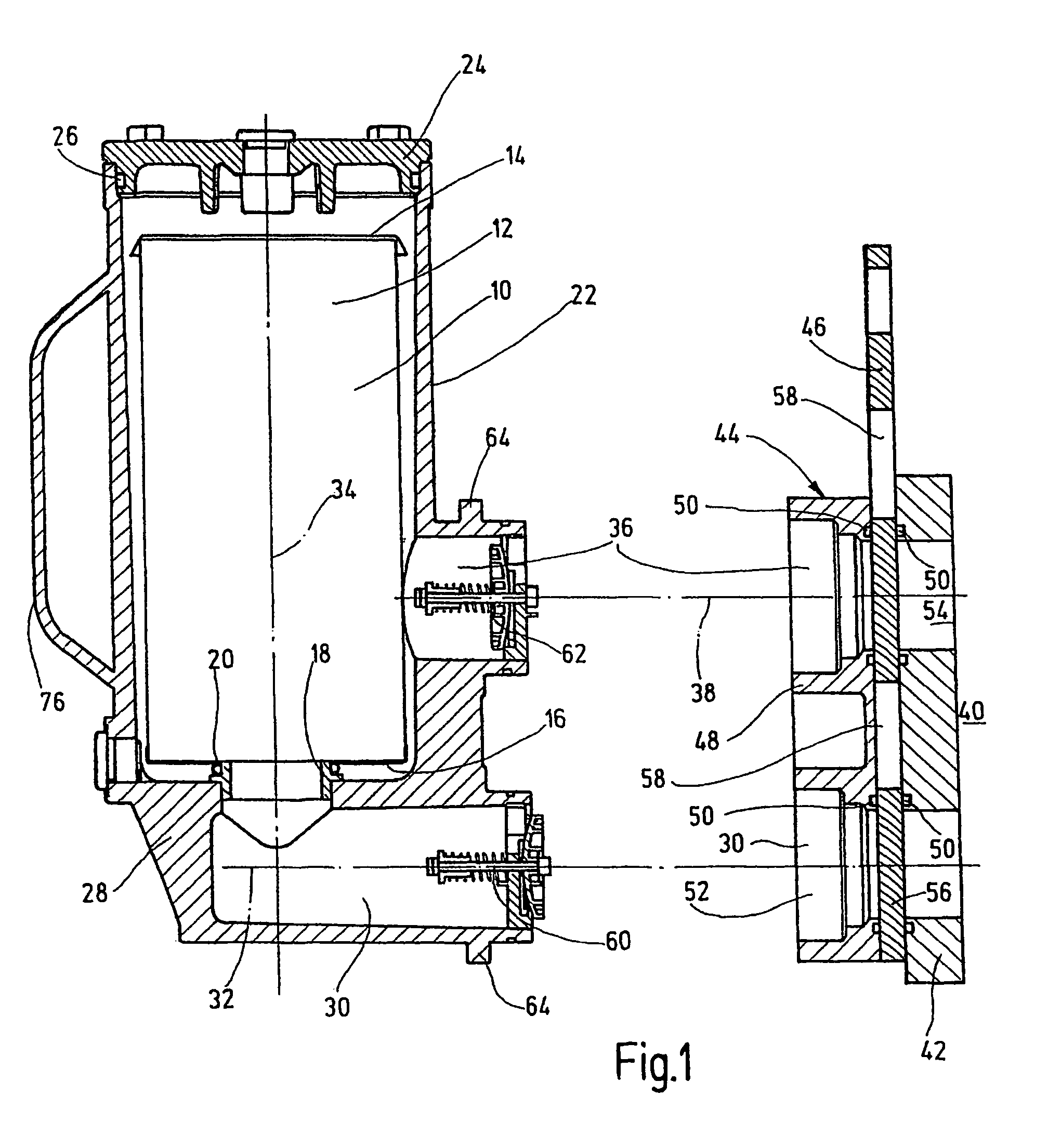

Radial sliding seal with subassembly for metering devices, and metering device with such a radial sliding seal subassembly

ActiveUS9180457B2Small geometryLow installationEngine sealsReagent containersEngineeringSliding contact

A metering device for use in syringes and pipetting piston-cylinder arrangements, including a sealing component working together with at least one pretensioning component. The sealing component comprises a sealing segment extending in the axial direction and in the circumferential direction. The sealing segment has a sealing surface facing in a first radial direction for sealing and sliding contact in at least the axial direction, is formed on a working surface formed on the outer surface of the piston rod facing toward the inner wall of the cylinder. The sealing segment also has a pretensioning surface extending in a second radial direction opposite to the first for engaging with the pretensioning component for transferring the radial pretensioning force, where the pretensioning component includes a spring carrier and a plurality of separately formed radial spring segments compliantly supported at least in the radial direction on the spring carrier.

Owner:HAMILTON BONADUZ AG

Integrated liquid cooling device and method thereof

InactiveUS20180195804A1Ensure safetySimple structureDigital data processing detailsSemiconductor/solid-state device detailsEngineeringIntegrated circuit

An integrated liquid cooling device comprises a housing, a first liquid reservoir, a second liquid reservoir, at least one first liquid channel for heat dissipation, a second liquid channel appressed to a heat source device, at least one third liquid channel for heat dissipation and a liquid transfer cycle driver; the first liquid reservoir is connected to the second liquid channel through the first liquid channel; the second liquid channel is connected to the second liquid reservoir through the third liquid channel; the first liquid reservoir and the second liquid reservoir are independent to each other and connected through the liquid transfer cycle driver; the liquid transfer cycle driver transfers the liquid in the second liquid reservoir to the first liquid reservoir. The invention saves the space and reducing the risk of leakage.

Owner:BLACKBEZT LIGHTING TECH CO LTD

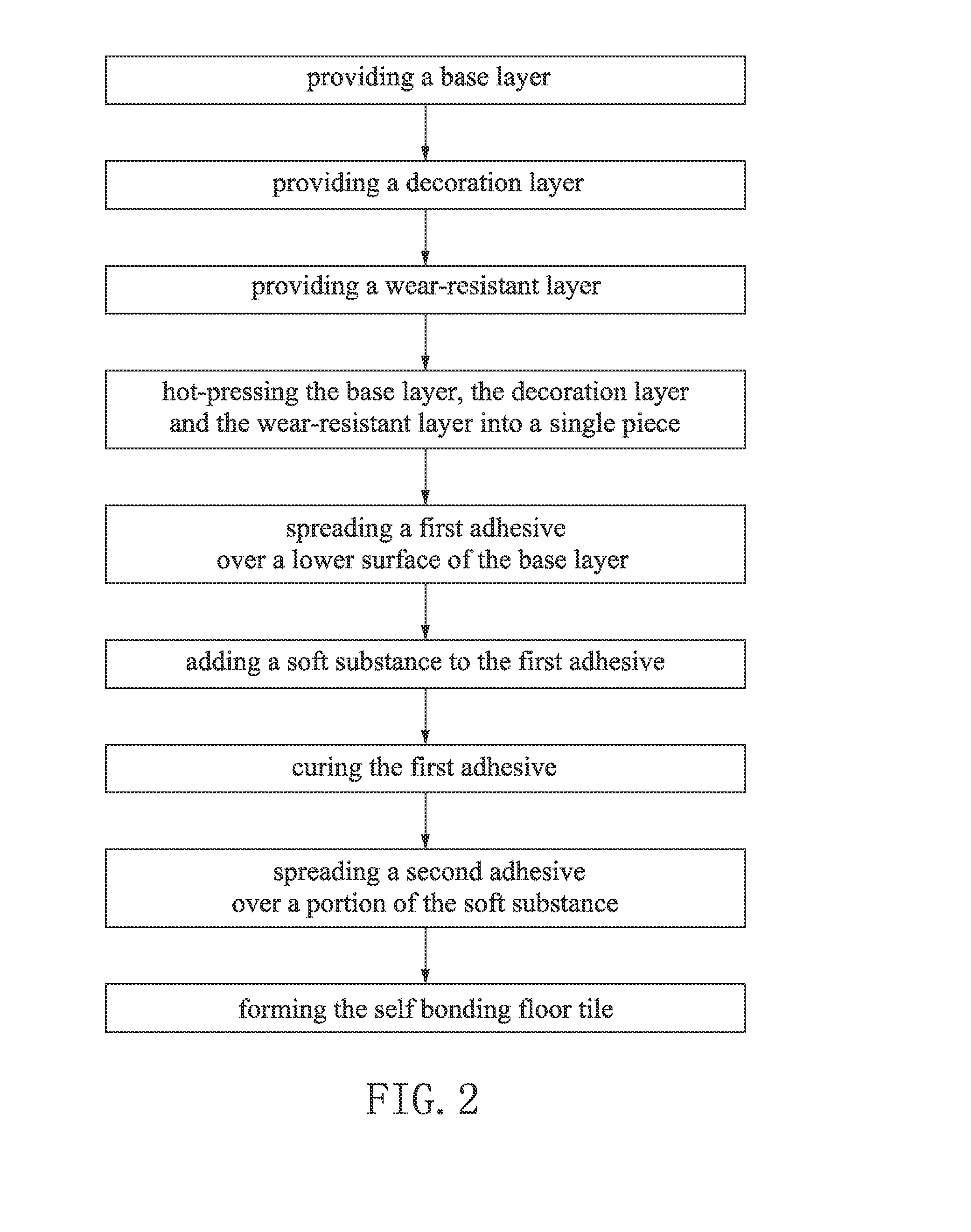

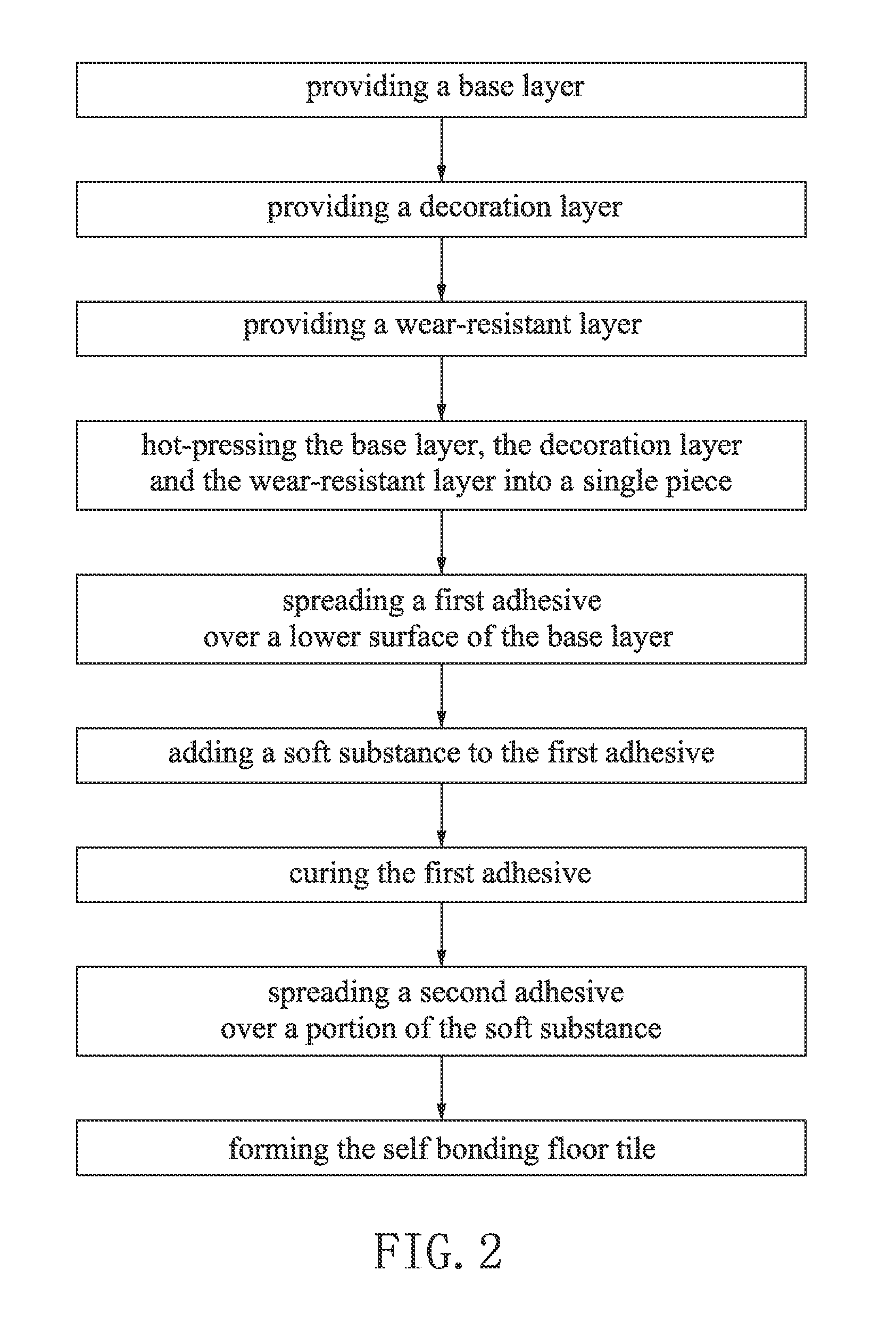

Self bonding floor tile and manufacturing method thereof

InactiveUS20120100332A1Easy to disassembleThe removal process is simpleWarp knittingCircular knitting machinesAdhesiveEngineering

A self bonding floor tile includes a main body and a self bonding layer connected with the main body. The self bonding layer includes an absorbate, a first adhesive and a second adhesive. The first adhesive connects the main body with the self bonding layer. At least a portion of the absorbate extends into the first adhesive, and at least a portion of the second adhesive penetrates into the absorbate for connecting the self bonding layer with a body to be decorated. A method for manufacturing the self bonding floor tile includes: providing a main body; spreading a first adhesive over the main body; providing an absorbate with porous or wick structure, and adding the absorbate to the first adhesive; spreading a second adhesive over the absorbate. The present self bonding floor tile can be quickly installed, easily and partly replaced with low installation and replacement cost.

Owner:SHANGHAI JINKA FLOORING TECH

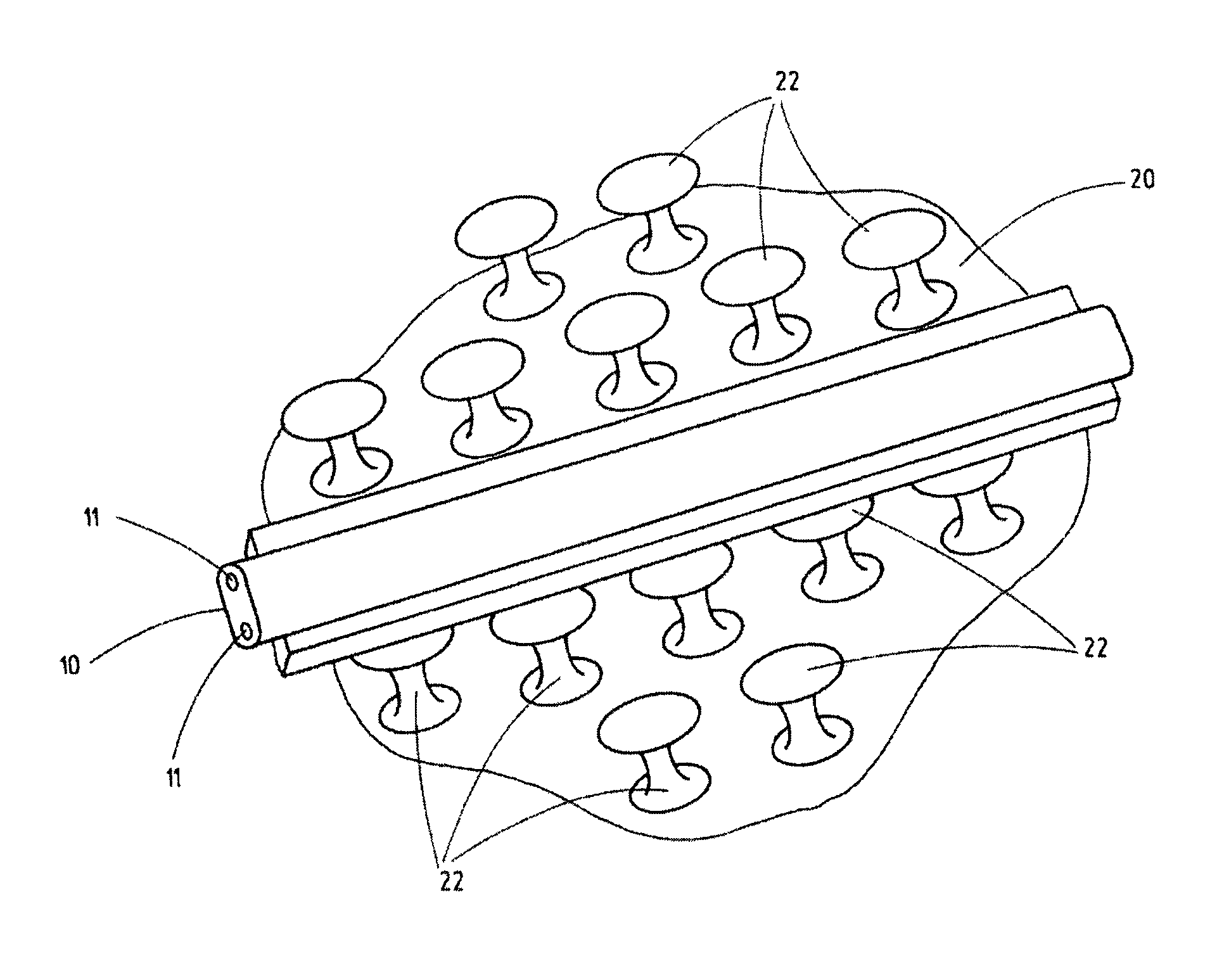

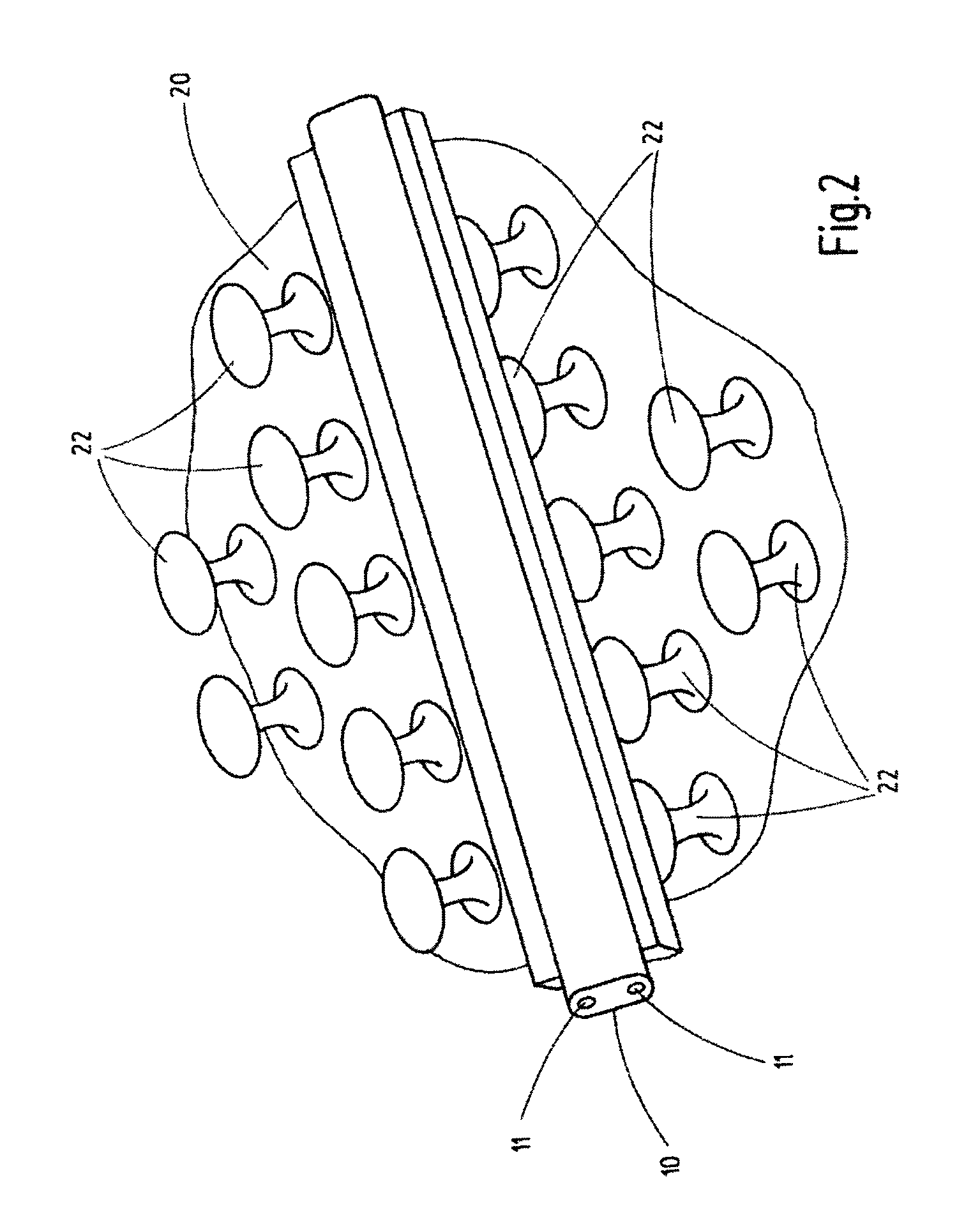

Fixing system and fastening element which can be used therefor

A fixing system for electronic and / or electric components—called E components in short—such as chips, circuits, transponders, cables (10) etc., has at least one first fastening element (12) having individual closure parts (14, 16) which, in interaction with corresponding closure parts (22) of a further fastening element (20), form an adhesive closure which can be opened and closed repeatedly. The respective E component can be connected to a support (30). The further fastening element (20) can be connected to the support (30), at least part of which has an adhesive layer and / or which is composed of an embedding compound. The adhesive layer or embedding compound produces the direct connection of the respective E component to the further fastening element (20) assignable to it. This connection requires only a very little amount of installation space.

Owner:GOTTLIEB BINDER

Corrosion control method and apparatus for reinforcing steel in concrete structures

InactiveUS20090127132A1Quick and low costLow installationMachining electrodesElectrical-based machining electrodesRebarOxide

Mixed-metal-oxide (MMO) coated precious-metal tape is installed directly on concrete surfaces using an electrically conductive adhesive, thereby obviating the need for slots, holes, cementitious grout or additional concrete. The electrically conductive adhesive is preferably formed by disposing mixed-metal-oxide (MMO) coated precious-metal particles in an adhesive layer. The tape anodes may be installed on the concrete surfaces including a shallow concrete cover or congested reinforcing steel without developing an electrical short circuit between the anode and the reinforcing steel. Overall the invention provides for quick and low cost installation on many concrete structures. Interconnections between the tape anodes and bare metal distribution elements may be made with conductive adhesive or spot welding.

Owner:FUNAHASHI MIKI

Skillet power system

InactiveUS20070175732A1Reduce installation costsReduce maintenance costsAc-dc network circuit arrangementsCharge manipulationElectricityElectrical conductor

The invention relates to conveyor systems with skillets adapted with connectors to enable power to be conveyed between skillets that are abutted together along a production area. With the skillets being electrically connected, the conductor only needs to supply power the electrical receiving device of a single skillet at any given time. The conductor in turn can be limited to a length of about one skillet, which reduces the wear, as well as installation, repair and maintenance costs.

Owner:JERVIS B WEBB INT CO

Reactor for performing biochemical processes

InactiveUS8304186B2Simple to executeEasy to processBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringIndustrial engineering

A reactor (1) for performing biochemical processes, particularly for extraction, purification, enrichment, sedimentation, comprising a container which is provided with at least one mouth (2) which is associated with closure means (3) of the removable type, the container having internally at least one process compartment (4), adapted to accommodate a sample of biochemical material to be processed, at least one containment chamber (5) for a process agent, and at least first means for transferring the process agent from the containment chamber to the process compartment.

Owner:SMART HOSPITAL +2

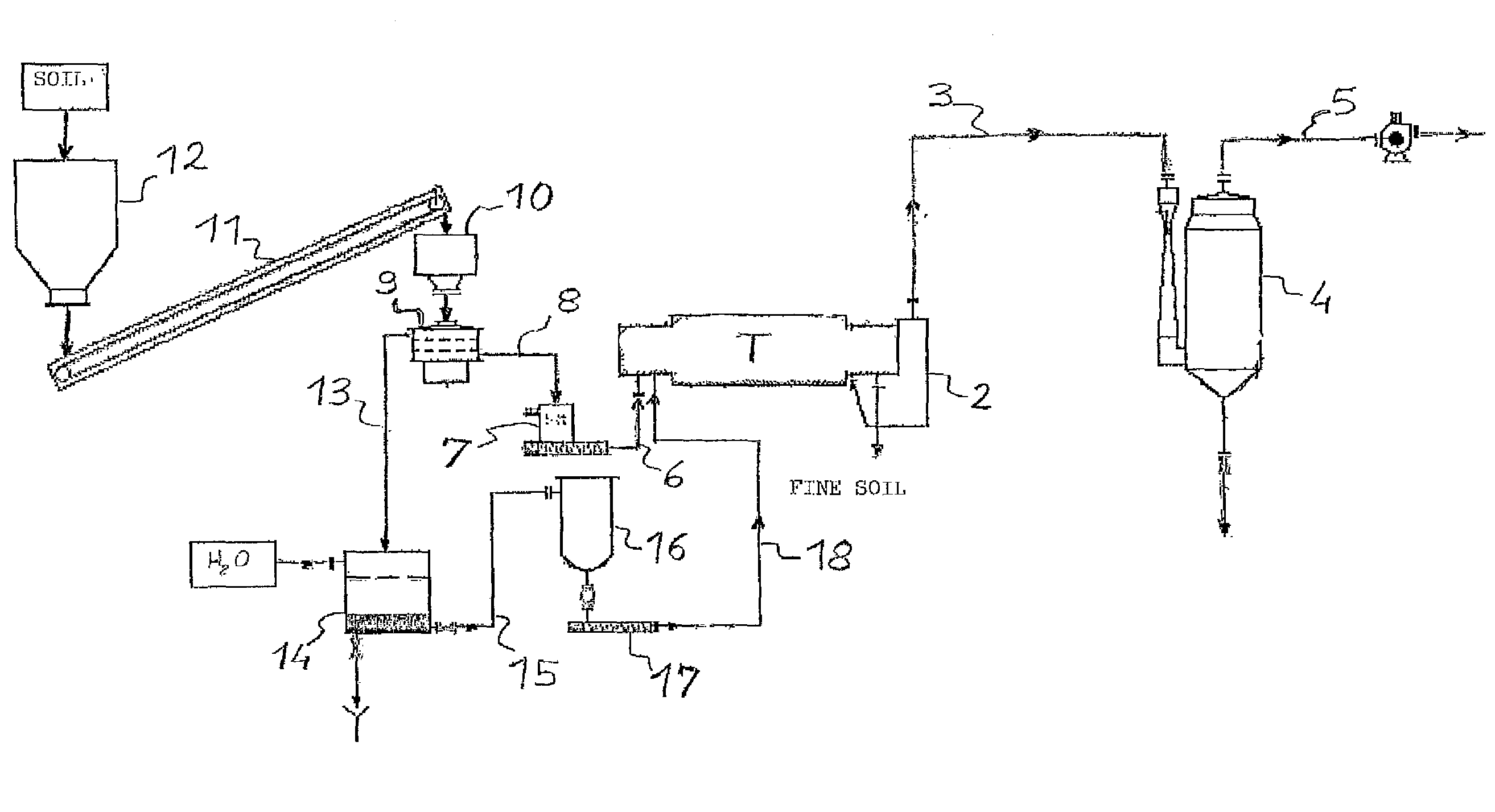

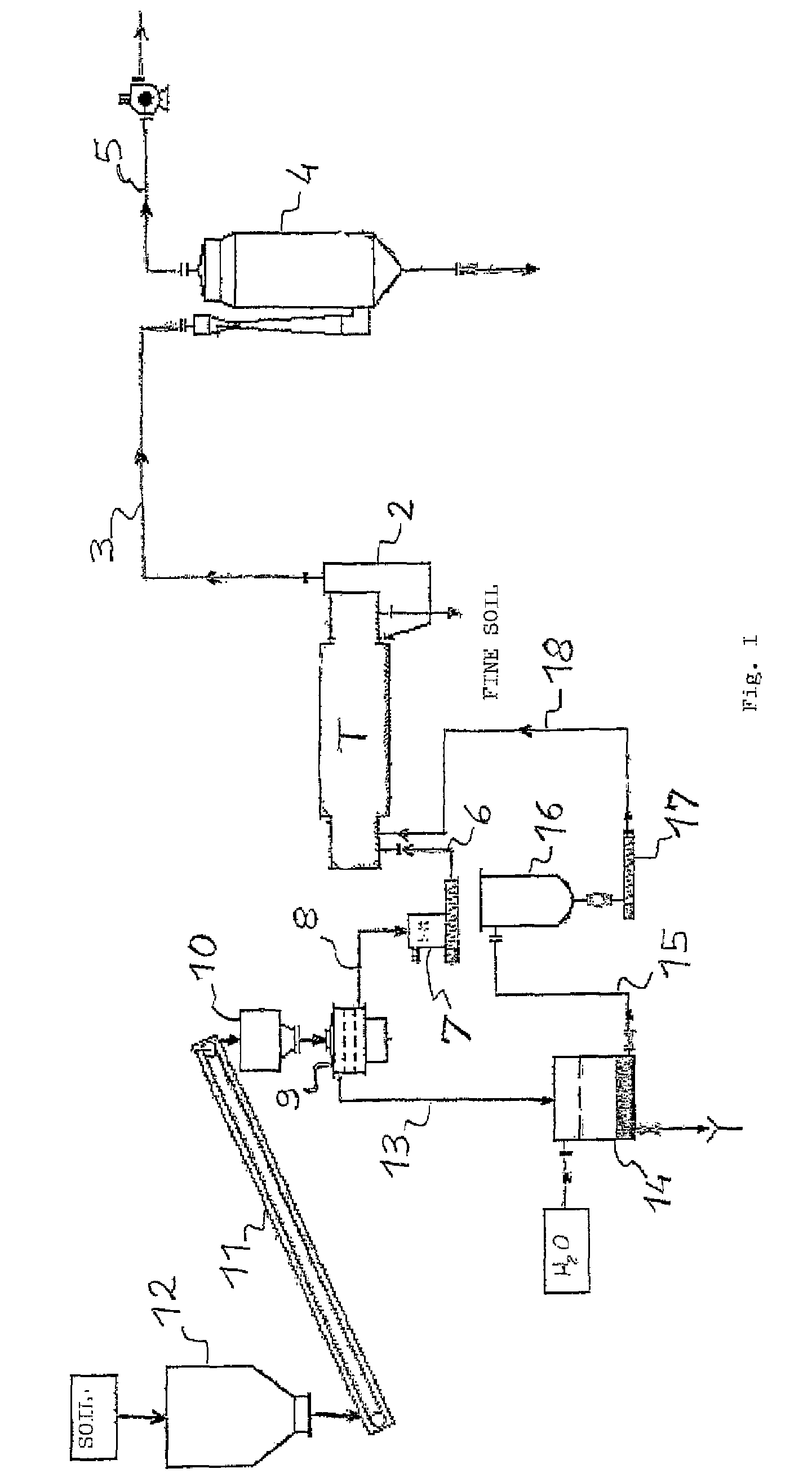

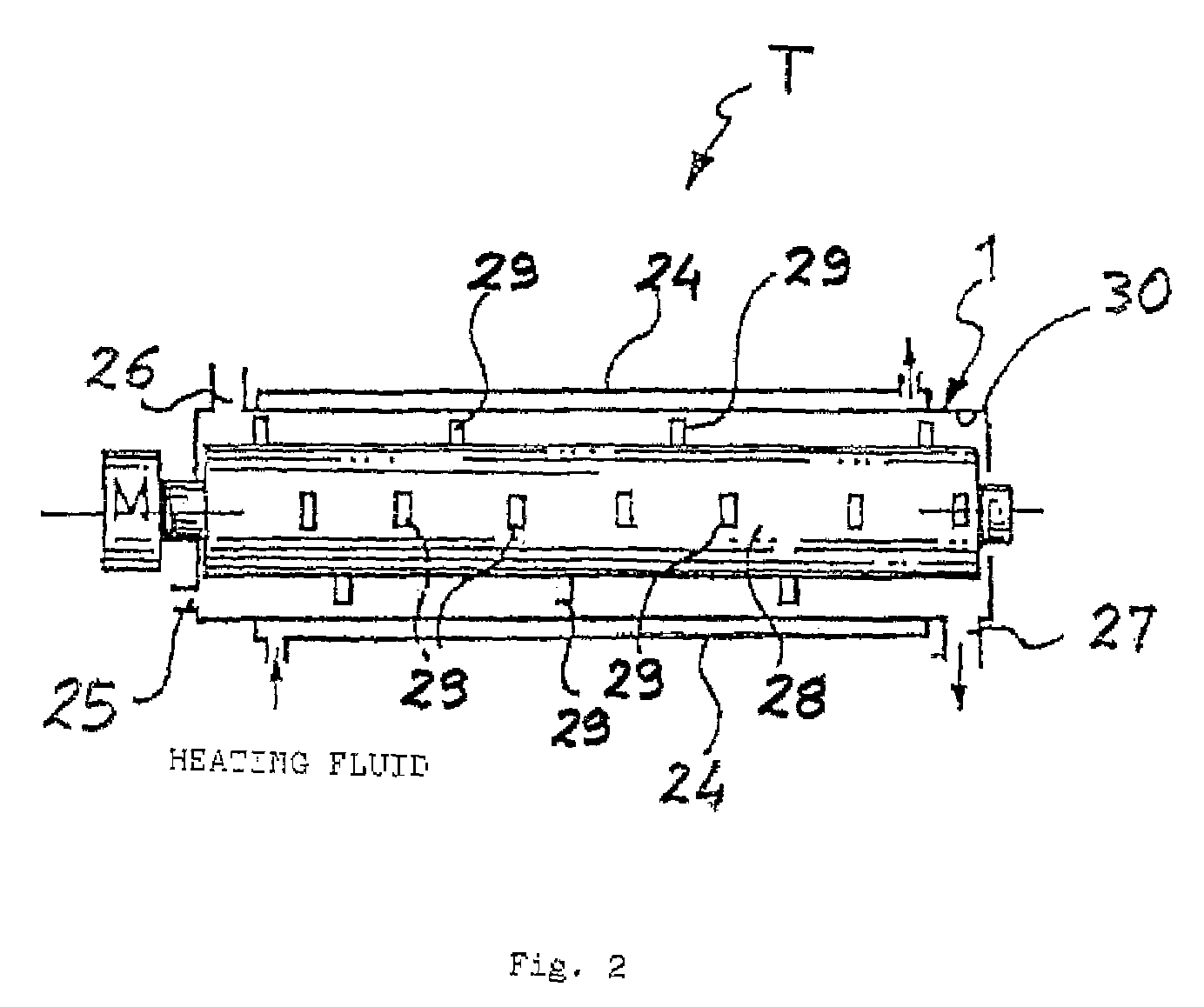

Method of remediating soil contaminated with polyhalogenated hydrocarbons

ActiveUS7674946B2Reduce energy consumptionLow costContaminated soil reclamationIncinerator apparatusSoil sciencePolychlorinated biphenyl

Method of remediating a soil contaminated by polyhalogenated hydrocarbons, in particular PCBs, PCDDs and PCDFs, comprising the steps of removing and sieving the soil to free it of stones and gravel; possibly regulating the moisture content of the sieved soil to a value of 10-30%; subjecting the sieved soil to thermal treatment while it flows in the form of a thin, turbulent, dynamic layer in contact with a wall heated to at least 250° C.; separating the thermally treated soil from the steam generated following such treatment, the soil being substantially free of the aforementioned polyhalogenated hydrocarbons.

Owner:VOMM IMPIANTI E PROCESSI

Device for adjusting and exchanging beamstops

ActiveUS20200400592A1Low installationGood coolingMaterial analysis using wave/particle radiationRadiation/particle handlingPhysicsElectric machinery

A beamstop arrangement for an x-ray-optical system is adjustable in an xy plane perpendicular to a z-direction for optimizing a ratio of useful radiation reaching a surface to interfering radiation of an x-ray beam in the z-direction. The beamstop arrangement comprises a plurality of beamstops of differing size and / or geometry arranged on an exchanging mount, which is installed on a carriage displaceable in the xy plane by means of a drive unit having at least one positioning motor. The multiple beamstops can be located in a vacuum, while the drive motors and all electronic components can be positioned outside the vacuum, so that no heat development takes place in the measurement region. Corruption of the measurement result due to a changed measurement background is thus avoided.

Owner:BRUKER AXS

Dual drive plate damper for hybrid electric vehicles

ActiveUS9243672B2Easy to installLow installationHybrid vehiclesYielding couplingEngineeringElectric vehicle

An assembly includes an engine output concentric with an axis, an input, a starting gear, a first drive plate secured to the engine output, including a rim supporting the starting gear, and arms extending radially outward from the axis, and a second drive plate rotatably secured to the input, and secured to the first drive plate at a location spaced radially outward from the axis.

Owner:FORD GLOBAL TECH LLC

Microwave power amplification apparatus and method thereof

ActiveUS9143094B2High detection sensitivityQuality improvementLaser detailsPower amplifiersRadio over fiberSignal-to-noise ratio (imaging)

Period-one nonlinear dynamics of semiconductor lasers are utilized to provide an apparatus for photonic microwave power amplification in radio-over-fiber links through optical modulation depth improvement. The microwave power amplification apparatus includes a microwave-modulated optical signal generation module and a microwave power amplification module. The amplification capability of the present microwave power amplification apparatus covers a broad microwave range, from less than 25 GHz to more than 60 GHz, and a wide gain range, from less than 10 dB to more than 30 dB. The microwave phase quality is mainly preserved while the microwave power is largely amplified, improving the signal-to-noise ratio up to at least 25 dB. The bit-error ratio at 1.25 Gb / s is better than 10−9 and a sensitivity improvement of up to at least 15 dB is feasible.

Owner:NAT CHENG KUNG UNIV

Self bonding floor tile

ActiveUS9562363B2Quick installationEasy replacement of partsConstruction materialLayered productsFiberAdhesive

A self bonding floor tile includes a main body and a self bonding layer connected with the main body. The self bonding layer includes an absorptive element, a first adhesive and a second adhesive. The first adhesive connects the main body with the self bonding layer. The absorptive element includes a plurality of fibers which are implanted into the first adhesive by flocking process with at least a portion of the absorptive element extending into the first adhesive, and at least a portion of the second adhesive penetrates into the other portion of the absorptive element for connecting the self bonding layer with a support body going to be decorated. The present self bonding floor tile can be quickly installed, easily and partly replaced with low installation and replacement cost.

Owner:FLOORING IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com