Drying equipment and drying method

A drying equipment, microwave technology, applied in the direction of drying solid materials, progressive dryers, lighting and heating equipment, etc., can solve the problems of low efficiency, environmental hazards, waste and waste gas, etc., to achieve high efficiency, save costs, and reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

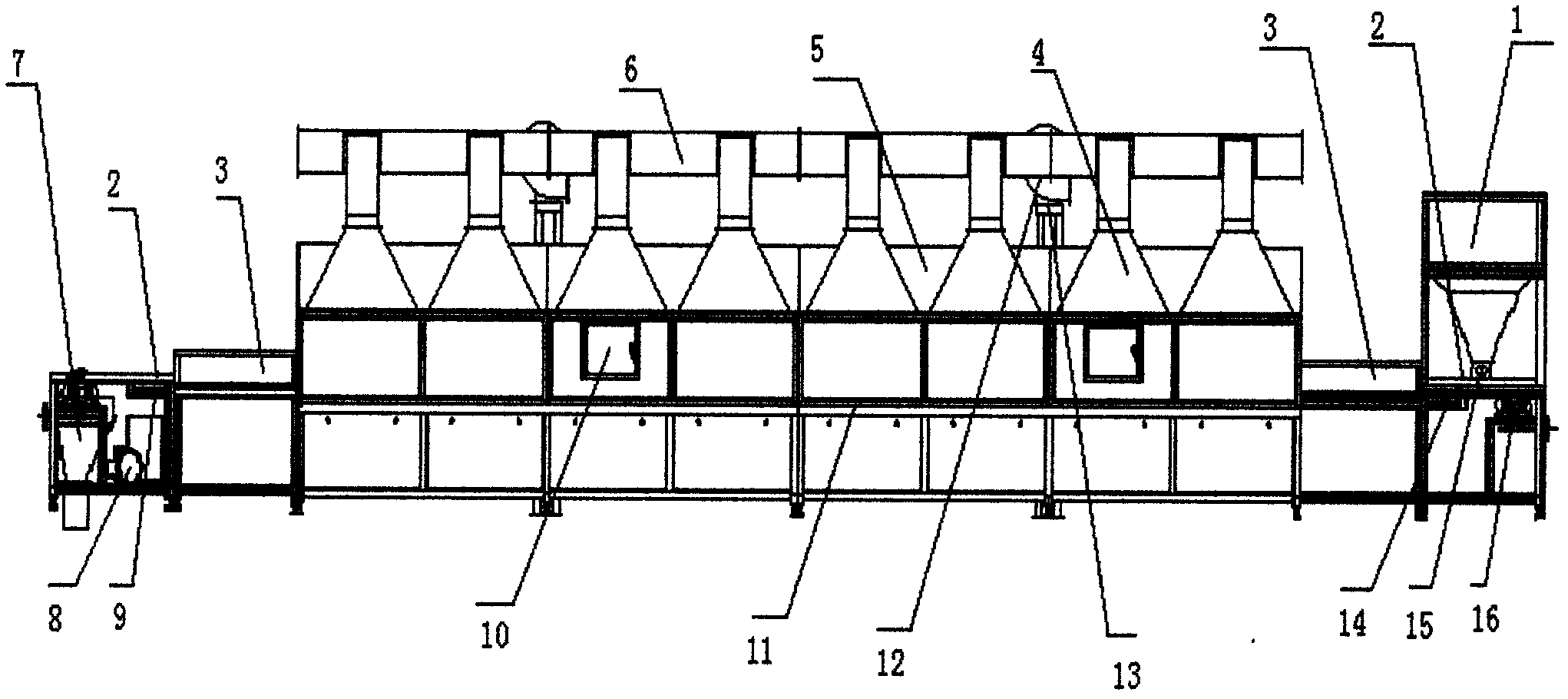

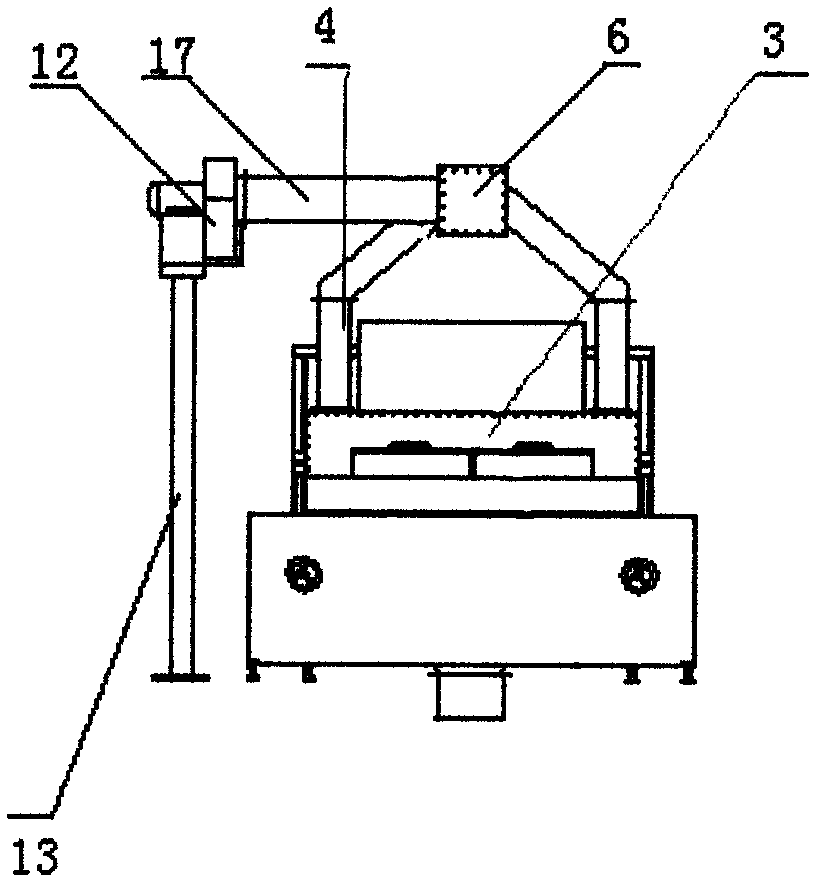

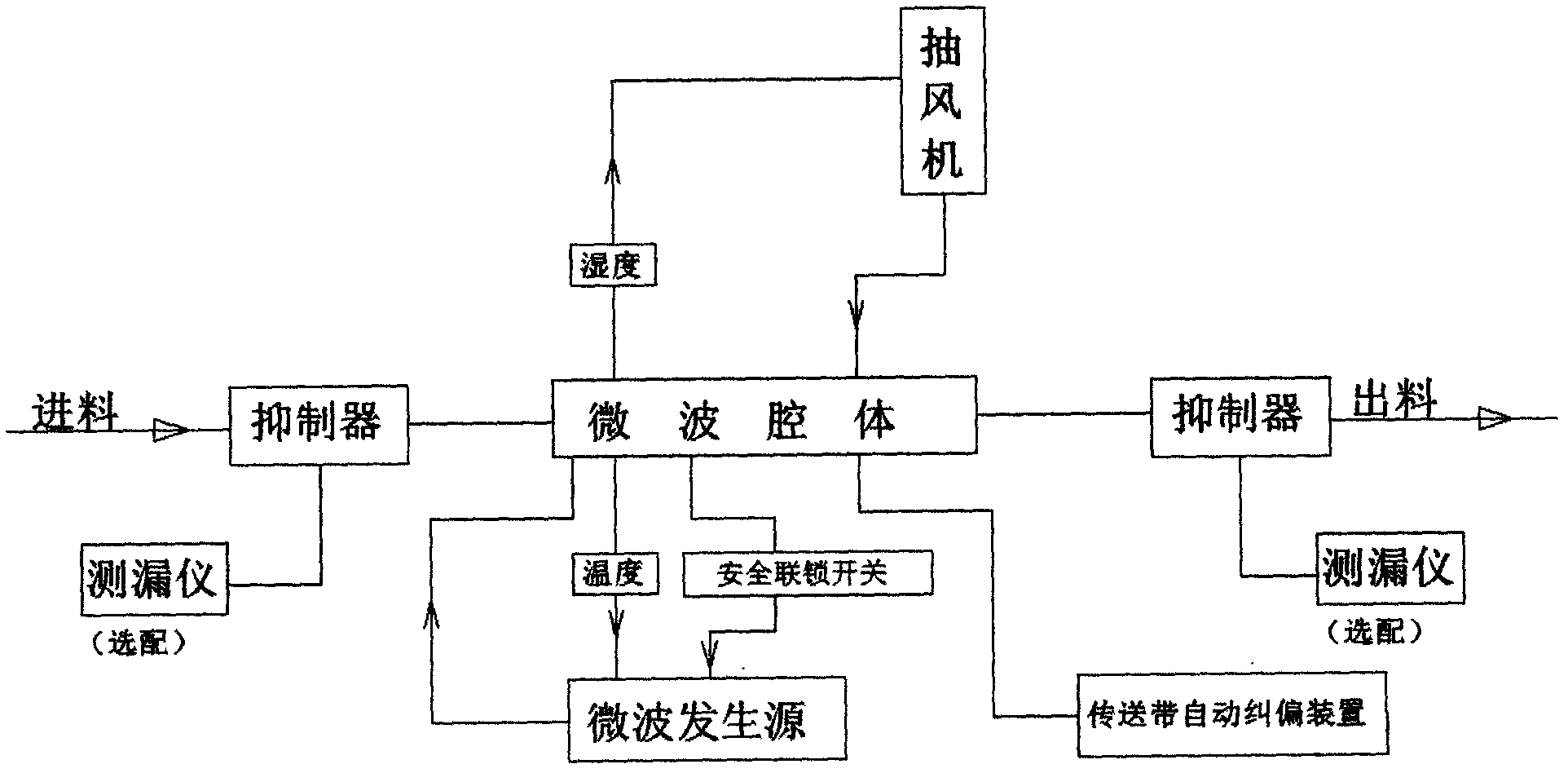

[0039] Such as Figure 1-2As shown, a drying device includes a distribution hopper 1, a conveyor belt 2, a suppression system 3, a microwave action chamber 4, an electric control system 5, a dehumidification pipeline 6, a lower hopper 7, a transmission system 8, an active support 9, and an observation window 10 , Equipment bracket 11, fan 12, fan bracket 13, passive bracket 14, dial shaft 15, dial motor 16, PVC pipe 17. A material shifting device is provided at the bottom of the material hopper 1, and the shifting device includes a shifting motor 16, a shifting shaft 15 and an electromagnetic vibration motor; the shifting shaft 15 is driven by the shifting motor 16 to flatten the material evenly Laying on the conveyor belt 2, the electromagnetic vibration motor adds a certain electromagnetic vibration force to the distribution hopper 1, so that the material can be discharged smoothly and evenly. The distribution bucket 1 is connected to the passive support 14 by bolts. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com