Angle measurement deviation processing of circular grating and shaft system skew compensation method

A compensation method and circular grating technology, applied to measuring devices, instruments, etc., to achieve the effect of improving angle measurement accuracy and operation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

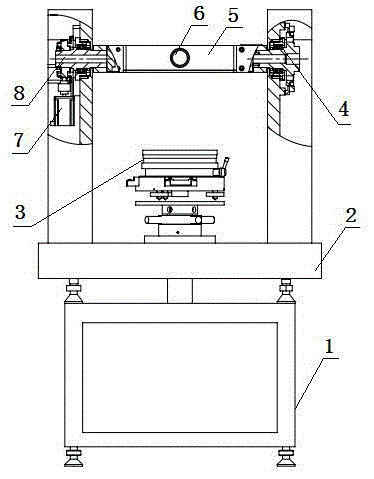

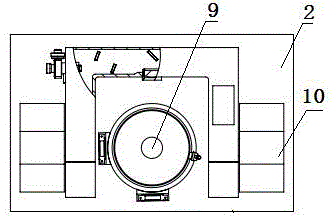

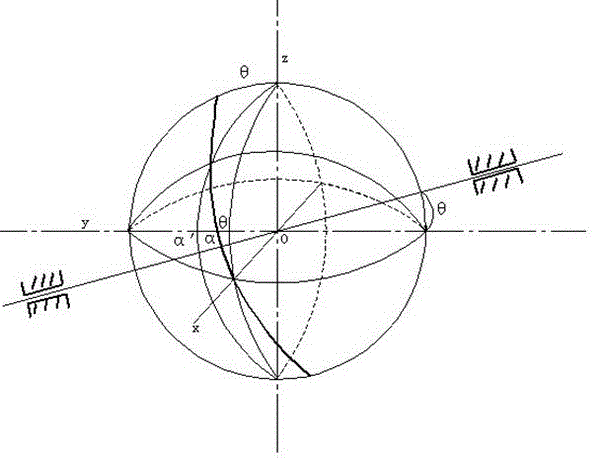

[0031] Circular grating angle measurement deviation processing and shafting skew compensation method, the specific steps are as follows:

[0032] (1) Use the FPGA to collect the real-time corner position information obtained by the reading head of the circular grating disc. After calculation and processing, the FPGA outputs the angle count value corresponding to the corner position, and transmits the angle count value to the central processing unit;

[0033] The angle-sensitive components of the automatic detection instrument for angle measurement and orientation equipment are metal circular gratings and reading heads, such as Figure 5 As shown, the reading head has two orthogonal rectangular wave signal output channels A and B, assuming that the sampling circuit is at t 0 Obtain the level value of channel A and B at all times as 01, at t 1 If the obtained value is 00 at any time, a combined value of 0100 is obtained. By looking up the pre-built counting increment table, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com