Control loop of safe and nondestructive testing of strength conveyor belt

A non-destructive testing and control loop technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of transportation material loss, affecting safety production, elongation, etc., to reduce loss and economic loss, avoid major safety accidents, and facilitate installation and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

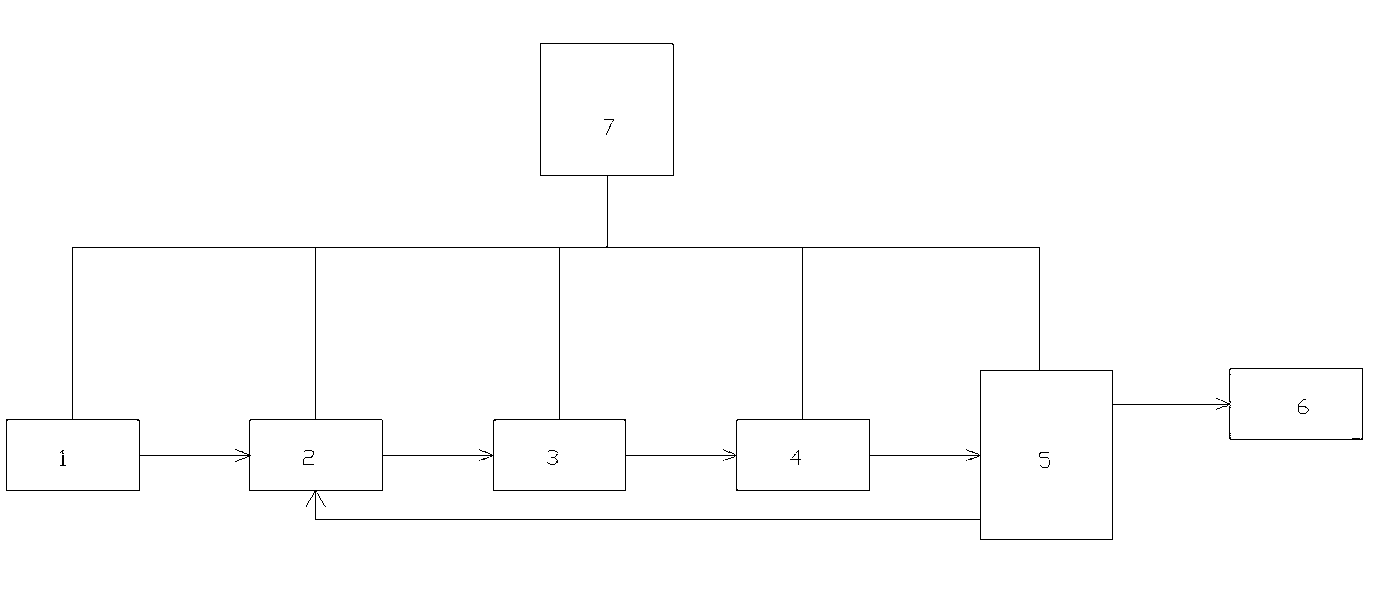

[0010] see figure 1 , the present invention includes an infrared emitter group 1, a switch circuit 2, a photoelectric conversion circuit 3, an acquisition circuit 4, and a controller 5 connected in sequence, the infrared emitter group 1, a switch circuit 2, a photoelectric conversion circuit 3, and an acquisition circuit 4. The controllers 5 are all connected to the power supply 7; the controller 5 is connected to an alarm circuit 6, and the controller 5 is connected to the upper computer through the RS485 communication interface.

[0011] Above-mentioned infrared ray emitter group 1 is made up of several infrared ray emitters that are arranged on the bottom of the conveyor belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com