Vacuum contactor for wind power generation

A technology of vacuum contactor and vacuum switch tube, which is applied in the direction of high-voltage air circuit breakers, circuits, electric switches, etc., and can solve the problems that cannot meet the needs of wind power generation, high current, high stability and reliability, and it is difficult to realize synchronous closing or opening, Unable to use high-power power generation equipment and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with embodiment.

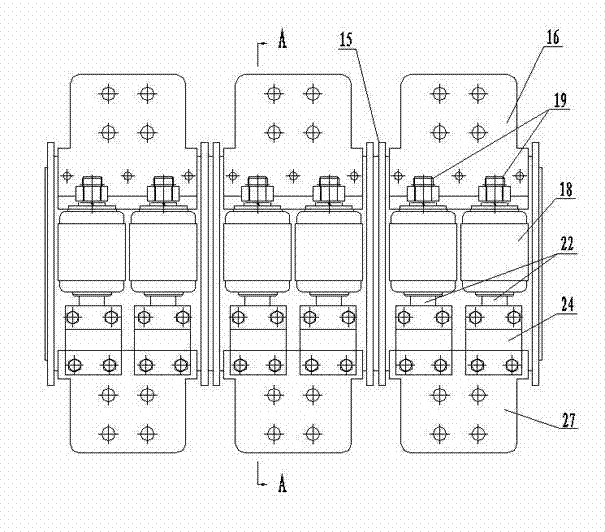

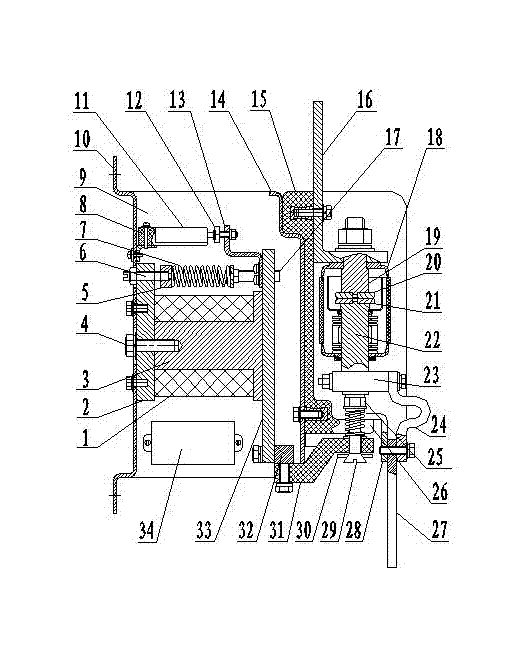

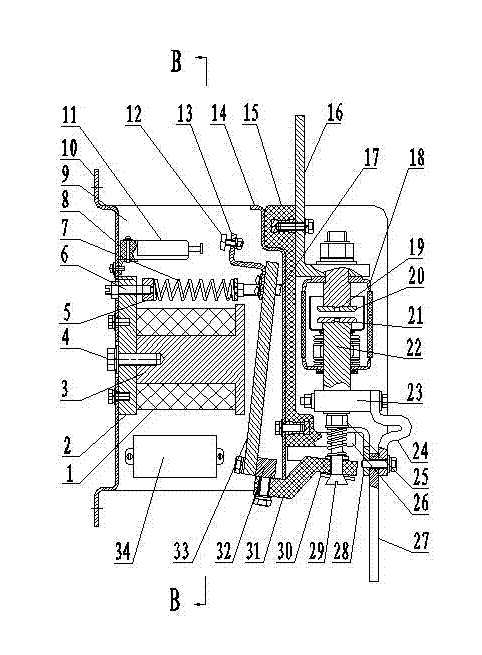

[0020] Such as figure 1 and figure 2 As shown, the vacuum contactor for wind power generation of the present invention includes a rear base plate 10 and a front base plate 14, the front base plate 14 and the rear base plate 10 are both iron plates, and the same vertical sides of the front base plate 14 and the rear base plate 10 pass through the side The plates 9 are connected together with fasteners, wherein the fasteners consist of bolts and nuts. Four static armature plates 2 are arranged in the middle of the inner surface of the rear base plate 10 , and the static armature plates 2 are fixed on the inner surface of the rear base plate 10 by means of screws. A static iron core 3 is arranged on the inner side of the static armature plate 2 , and the static iron core is fixed together with the static armature plate 2 by means of bolts 4 . The coil 1 is wound on the static i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com