Monitoring method of millisecond annealing process stability

A millisecond annealing and stability technology, applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of low millisecond annealing process accuracy, unreusable wafers to be monitored, and increased production costs. , to achieve the effect of high accuracy, convenient compensation and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

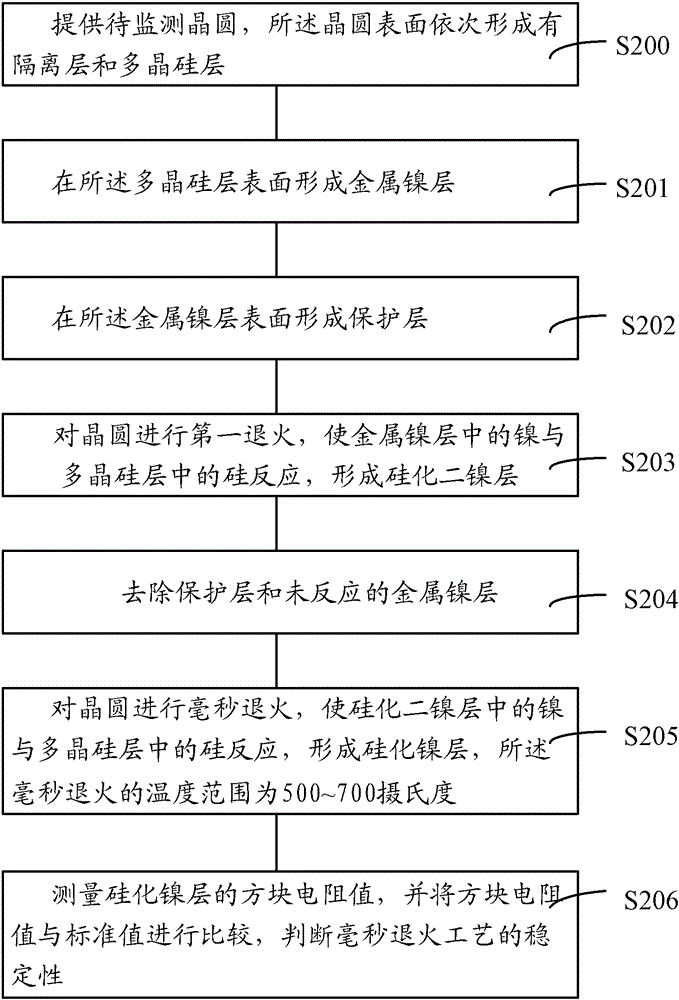

Method used

Image

Examples

Embodiment Construction

[0034] In the process of monitoring the stability of the rapid thermal annealing process, the inventor found that after the ion implantation of the wafer to be monitored, due to the difference in the thickness of the wafer and the depth of ion implantation, the implanted area cannot be removed by etching The silicon material realizes the repeated utilization of the monitoring wafer, which increases the production cost.

[0035] The inventors have further studied and found that when the existing monitoring method for the stability of the rapid thermal annealing process monitors the stability of the millisecond annealing process, the sheet resistance value on the monitoring wafer and the temperature of the millisecond annealing process are non-linear changes, making the monitoring The error increases, and the accuracy of monitoring is low, especially for low temperature areas, this effect is particularly serious.

[0036] In order to solve the above problems, the inventor propos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com