Electrostatic Discharge Protection Device

A technology of electrostatic discharge protection and voltage rail, which is applied in the direction of circuits, electrical components, electric solid devices, etc., can solve problems such as difficult triggering, damage of circuit components, and inability to effectively realize electrostatic discharge protection functions, so as to reduce the trigger voltage and reduce the damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

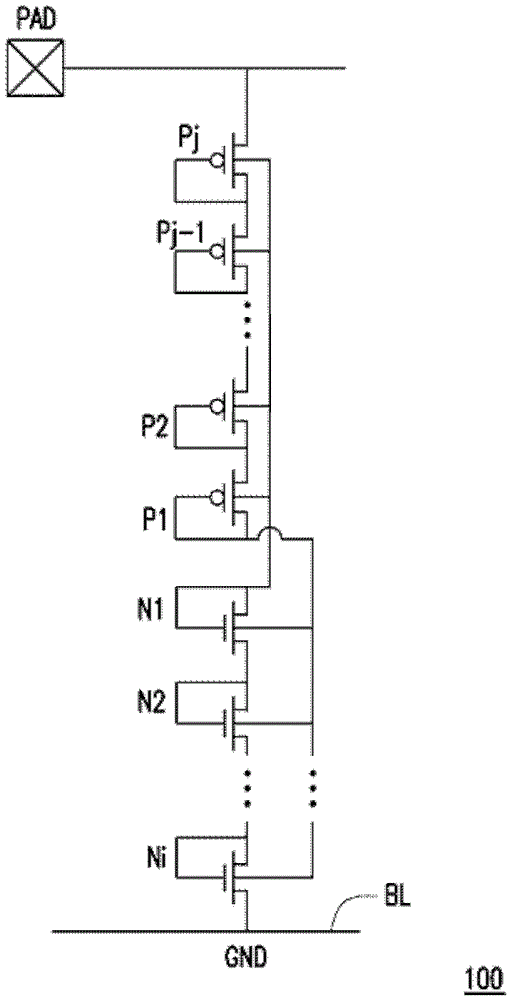

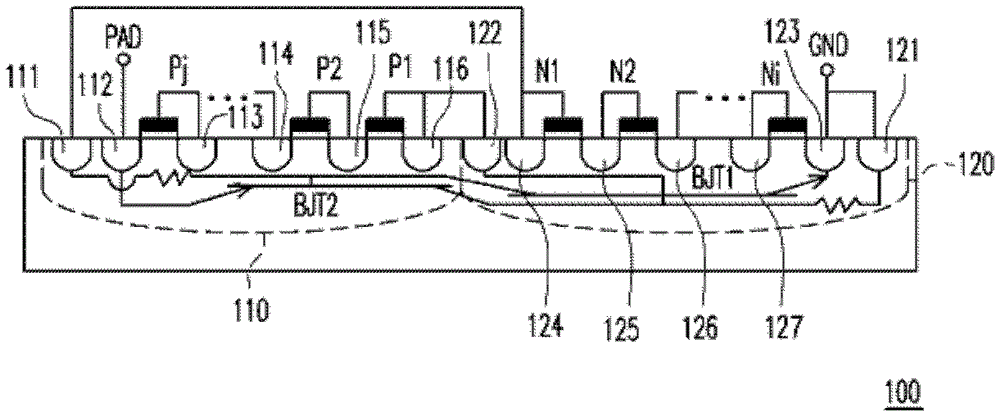

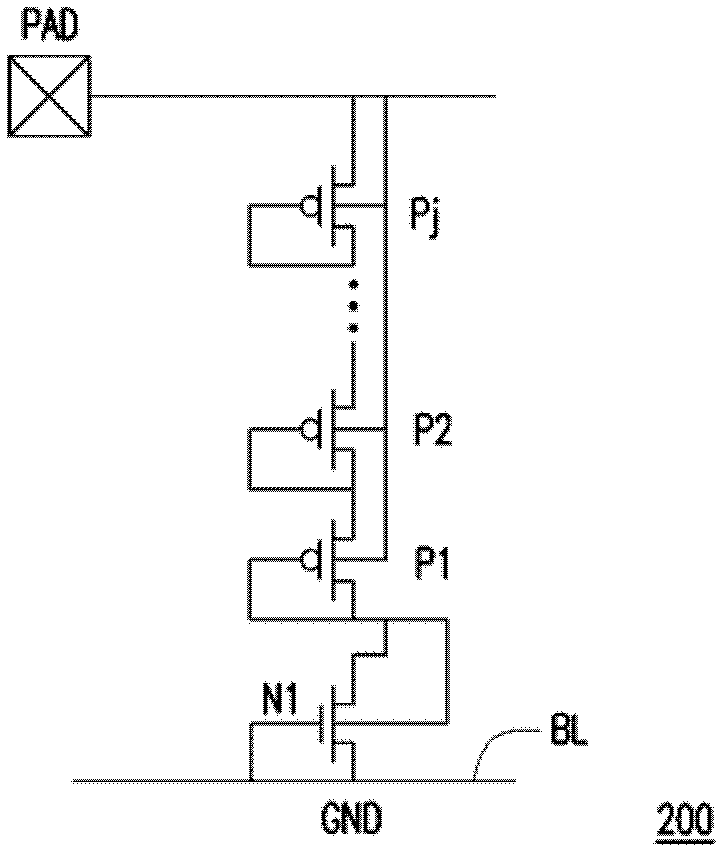

[0028] Please refer to Figure 1A , Figure 1A A schematic diagram of an ESD protection device 100 according to an embodiment of the present invention is shown. The ESD protection device 100 includes transistors P1 -Pj and transistors N1 -Ni. Wherein, the control terminal (gate) and the second terminal (drain) of the transistor Pj are coupled to each other, and the first terminal (source) of the transistor Pj is coupled to the pad PAD. The base of the transistor Pj is coupled to the transistor N1, and the drain of the transistor Pj is coupled to the next-stage transistor Pj-1.

[0029] In addition, the transistors P1 to Pj-1 are connected in series between the transistor Pj and the transistor N1. Taking the transistor P2 as an example, the base of the transistor P1 is coupled with the bases of the transistors P2 to Pj, and the drain of the transistor P1 is connected to The gate is coupled to each other, the drain of the transistor P1 is coupled to the bases of the transistors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com