A Trench Type Insulated Gate Field Effect Transistor

A field effect transistor and insulated gate technology, applied in the field of trench type insulated gate field effect transistors, can solve the problems of IGBT losing gate control capability, increasing the probability of latch-up effect, IGBT permanent burning, etc., so as to reduce latch-up effect. , reduce the probability of occurrence, reduce the effect of base resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

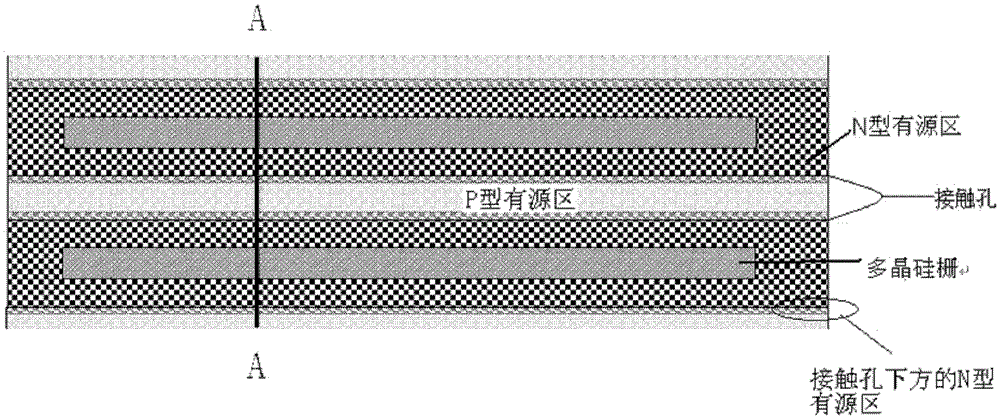

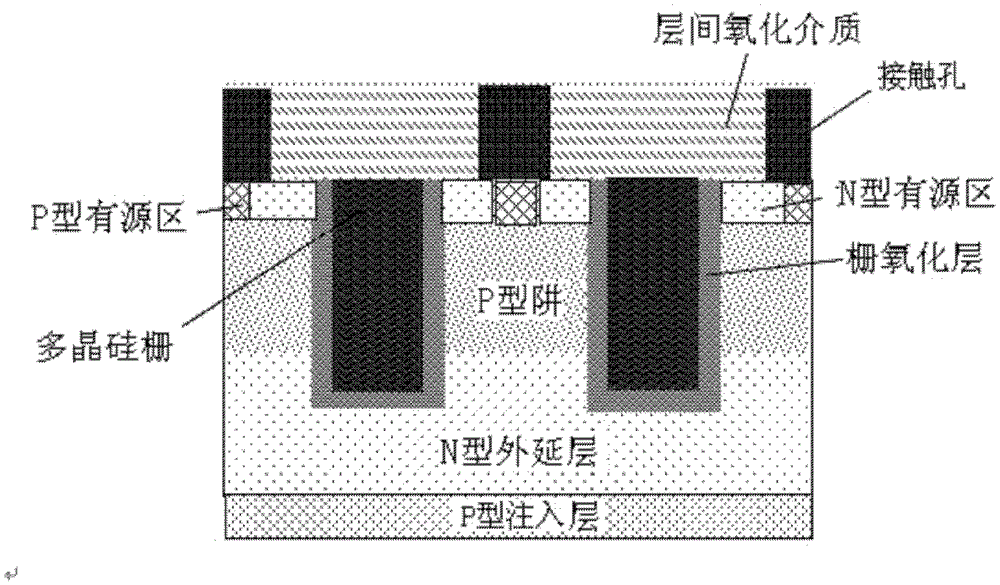

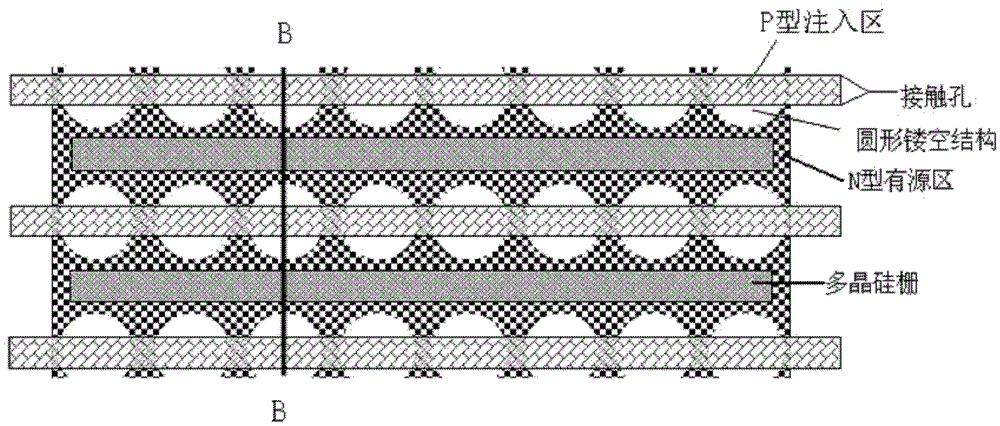

[0014] like image 3 , Figure 4 As shown, the first embodiment of the trench type insulated gate field effect transistor of the present invention includes: a P-type injection layer is formed under the N-type epitaxial layer, a trench is formed on the upper part of the N-type epitaxial layer, and a gate oxide layer and a gate oxide layer are formed in the trench. A polysilicon gate, a P-type well and an N-type active region are formed on both sides of the trench, and the N-type active region is located above the P well, wherein a circular hollow structure is formed in the N-type active region, and the circular hollow structure No doping, the diameter of the circular hollow structure is 1um, the interlayer oxide medium is formed above the trench, the circular hollow structure and the N-type active region, there is a P-type implantation region under the contact hole, and the contact hole penetrates the layer The intermediate oxide dielectric connects the N-type active region an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com