Printed circuit board

A printed circuit board and board body technology, applied in the direction of printed circuit, printed circuit, printed circuit components, etc., can solve the problems of poor anti-electromagnetic interference ability of printed circuit board 100, unfavorable interference current derivation, high grounding impedance, etc., to achieve improved Anti-electromagnetic interference ability, reduce production cost, and reduce the effect of grounding impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

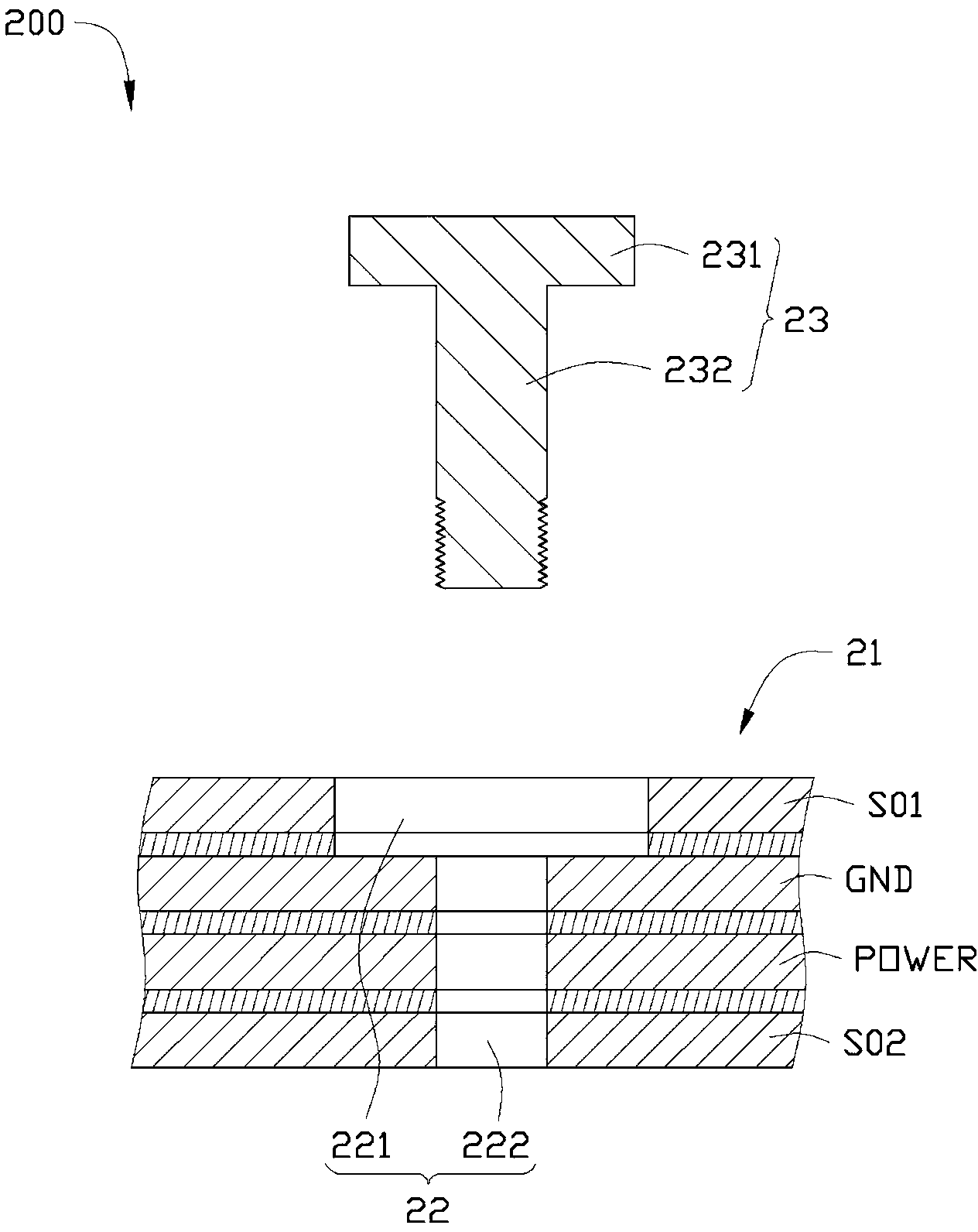

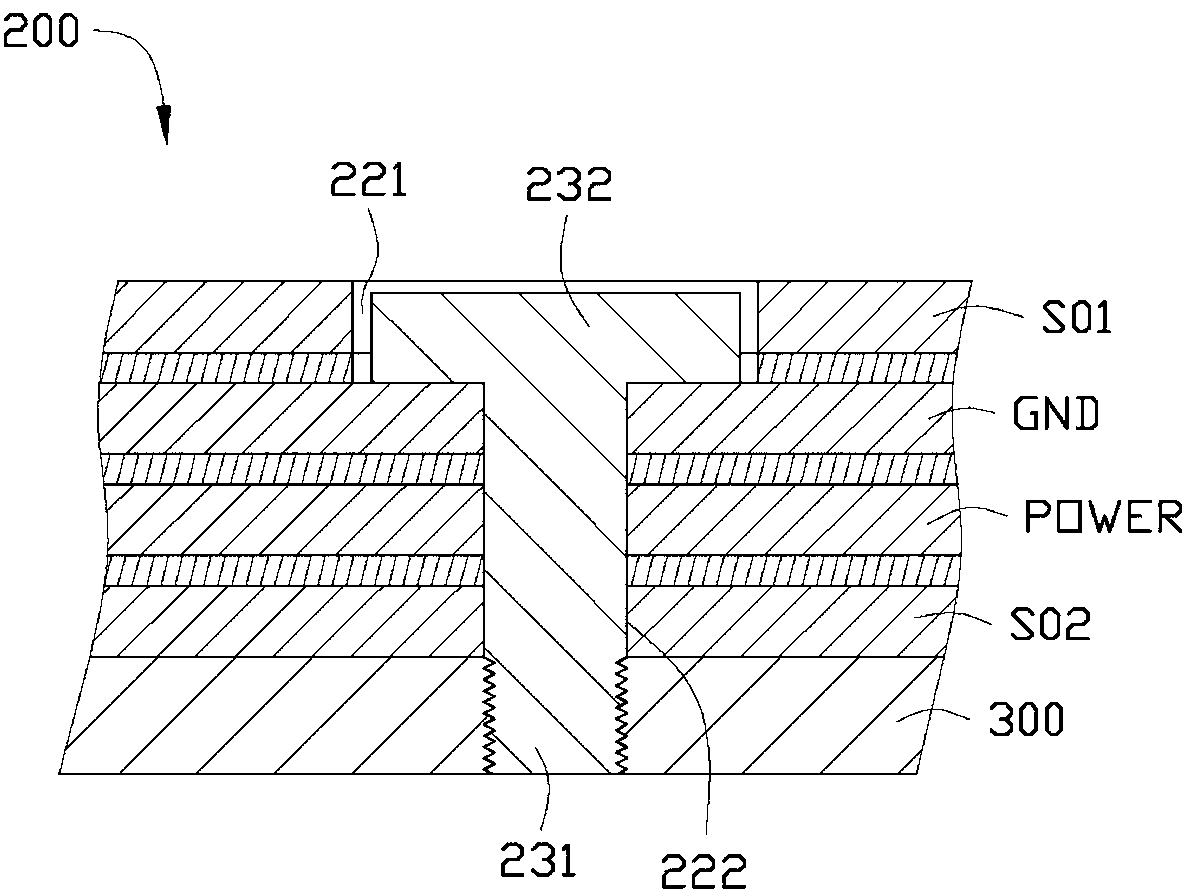

[0013] see figure 2 A preferred embodiment of the present invention provides a printed circuit board 200, which is installed in electronic devices such as computers and servers, and is fixedly connected to the grounding element of the electronic device.

[0014] The printed circuit board 200 includes a board body 21 . In this embodiment, the board body 21 is a four-layer circuit board, including a first signal layer S01 , a ground layer GND, a power layer POWER and a second signal layer S02 stacked in sequence. Wherein, a dielectric substrate (not shown) is disposed between the first signal layer S01 , the ground layer GND, the power layer POWER and the second signal layer S02 .

[0015] The board body 21 defines a through hole 22 , and the through hole 22 includes a locking hole 221 and a through hole 222 . The locking hole 221 penetrates from the top of the board 21 , that is, the first signal layer S01 to the ground layer GND. The through hole 222 penetrates from the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com