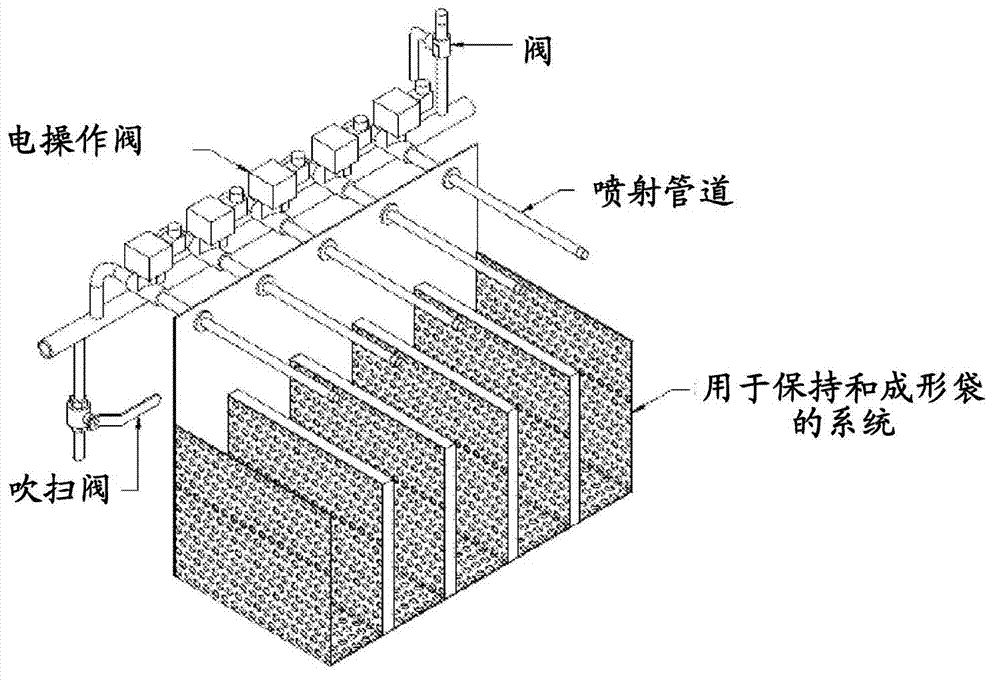

Equipment for producing cooling packs consisting of a shell made of a porous material containing an amount of carbon-dioxide snow enclosed and retained inside the casing

A technology of porous materials and carbon dioxide, which is applied to special packaging objects, household refrigeration devices, packaging, etc., and can solve problems such as complex operations with little flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

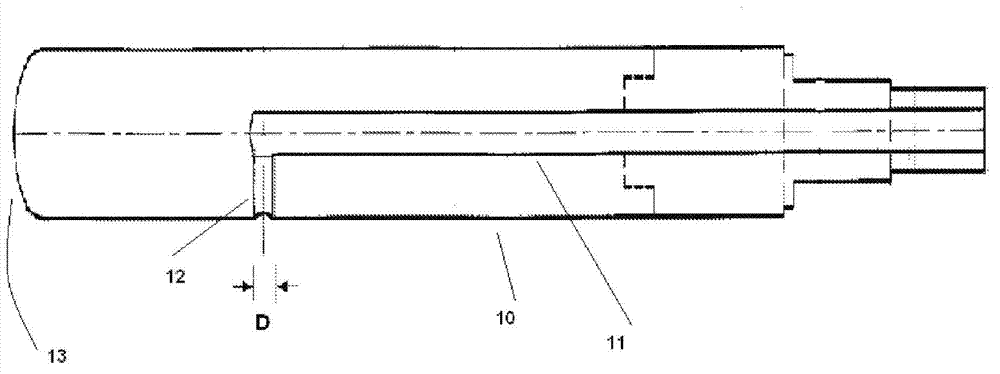

[0044] figure 2 is possible to assemble in figure 1 A schematic cross-sectional view of an embodiment of the injection pipeline 10 according to the present invention on the device:

[0045] - its closed end 13 has a generally circular shape;

[0046] - At a position along the spray duct (here 85 mm from the rounded end) there is a single threaded orifice 12 with a given diameter D (eg 8 mm) into which the nozzle can be screwed.

[0047] - This orifice 12 is in fluid communication (inner pipe 11 ) with an electrically operated valve corresponding to the injection pipe and said electrically operated valve is located between the injection pipe 10 and the electrically operated valve, for example by welding in the pipe system (electrically operated valve not shown here for clarity).

[0048] According to one embodiment of the present invention, all injection pipelines of the bagging machine are according to figure 2 (ie, each jet pipe has only one orifice, all orifices of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com