Motor cabin with variable frequency resonant cavity

A technology of frequency resonance and motor compartment, which is applied in the field of vacuum cleaner motors with noise reduction structure, to achieve reasonable utilization, small occupied space and increased sound energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in combination with specific embodiments.

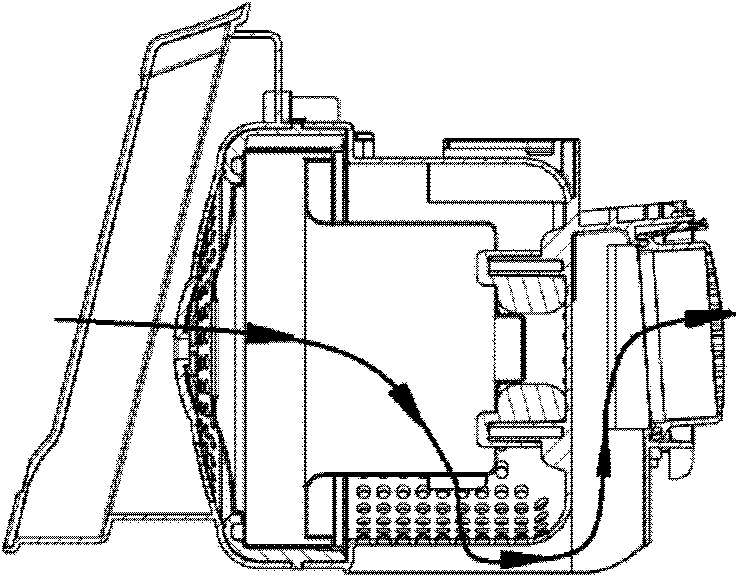

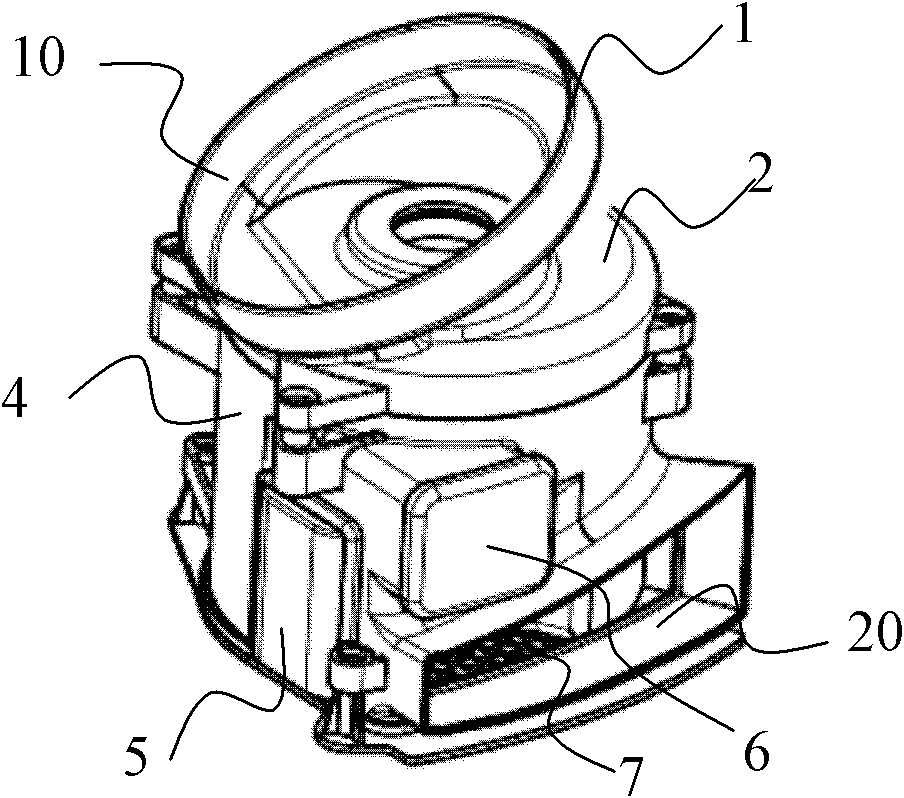

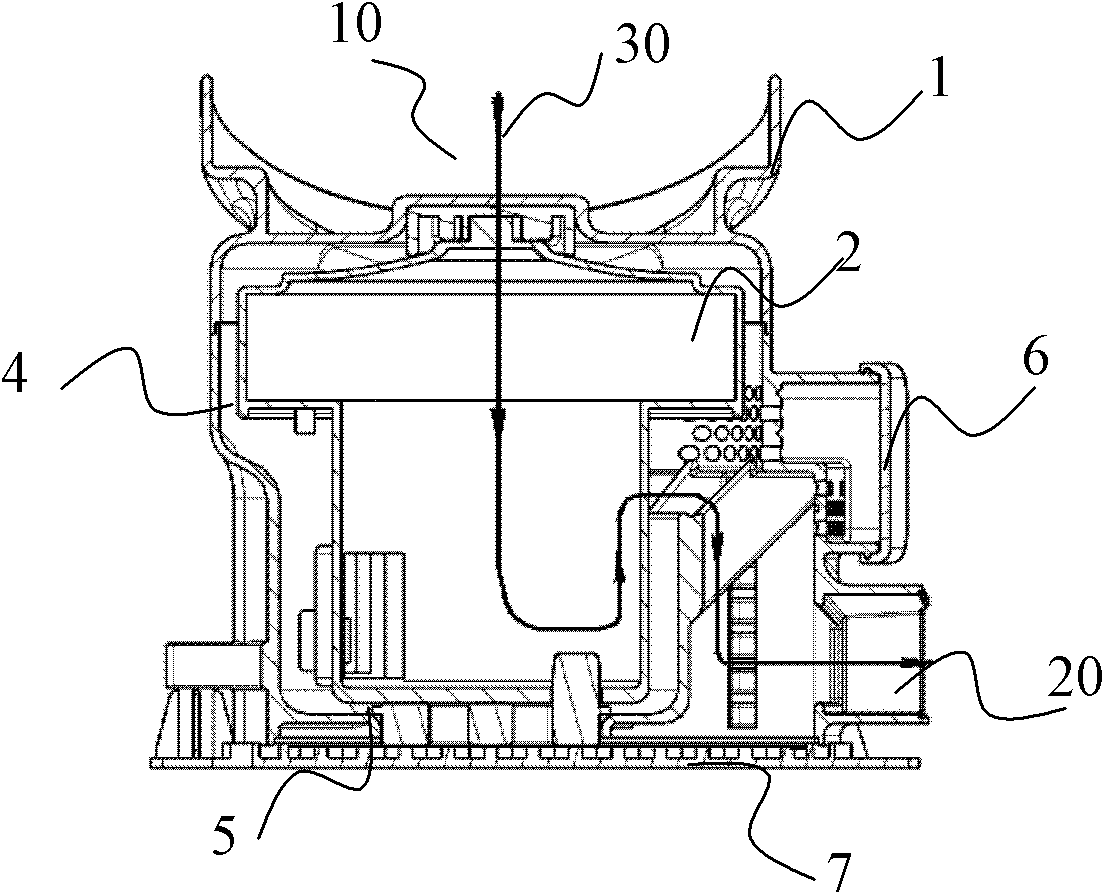

[0030] Such as figure 2 with Figure 4 As shown, the present invention has a motor compartment with a variable frequency resonant cavity, including a motor cover 1, a motor assembly 2, a vibration-isolation rubber pad 3, a motor case 4, a partition type muffler 5 and a lower bottom plate 8, and the motor The top of the cover 1 is provided with a suction port 10 , and an exhaust cavity 20 is formed outside the exhaust filter 5 .

[0031] On the motor casing 4, a variable frequency resonant cavity 6 is formed by a cavity protruding to the outside of the motor casing at the top of the exhaust cavity 20, such as figure 2 with image 3 As shown, the outer wall of the variable frequency resonant cavity 6 is a soft end, that is, a soft backplane is used as the end of the resonant cavity, as Figure 4 shown.

[0032] Image 6 The working principle of the variable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com