Conveyor belt roller carrier shaft flat block processing method

A processing method and idler shaft technology, applied in metal processing equipment, manufacturing tools, milling devices that can be installed on machine tools, etc., can solve the problem of affecting assembly operations and production efficiency, complicated workpiece inspection methods, and high labor intensity of operators and other issues, to achieve the effect of improving work efficiency and product quality, saving labor costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

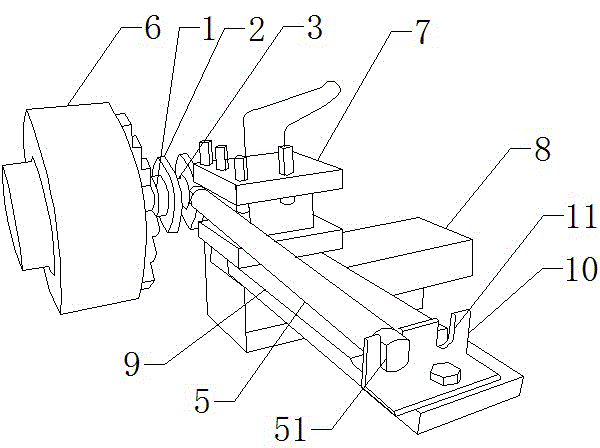

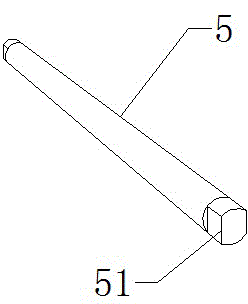

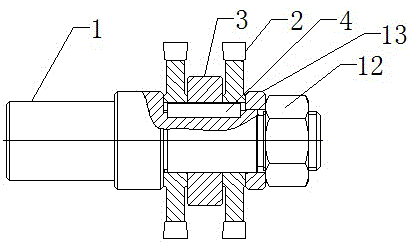

[0023] Different from the traditional squaring processing on a milling machine or a planer, the present invention uses a lathe to process the squaring of the idler shaft. Generally, when a lathe is used to process a workpiece, the workpiece to be processed is fixed on the lathe chuck, and the tool is fixed on the tool holder. During processing, the workpiece to be processed is driven by the lathe spindle to rotate, and the tool holder is perpendicular to the axis of the lathe spindle for turning operations. In the flat square processing method of the idler shaft of the belt conveyor provided in this example, the fixed position of the tool and the workpiece to be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com