Locomotive traction motor axle suspension bush machining device

A technology for traction motors and processing devices, which is applied to positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems affecting the working performance of the inner surface of the bearing pad Babbitt alloy, hidden dangers of driving, and poor lubrication, etc., to achieve improvement Work reliability, safe and reliable operation, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

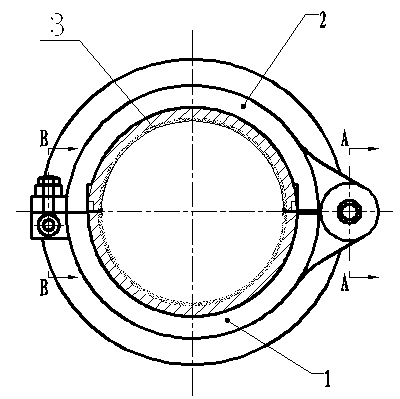

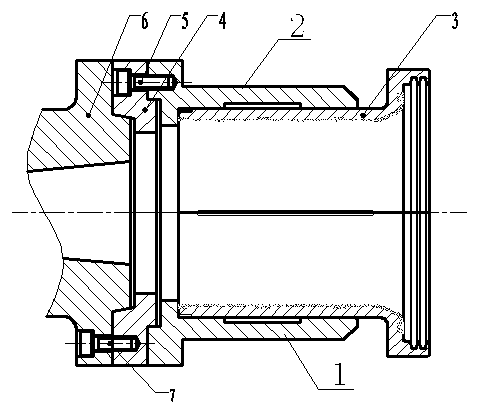

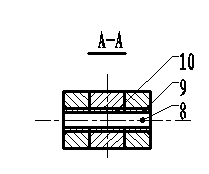

[0013] like figure 1 , 2 , 3, and 4, the processing device of the locomotive traction motor bearing bush 3 is composed of an upper carcass 2 and a lower carcass 1, and the upper and lower carcass 2, 1 are respectively a semicircular cylinder and two semicircular cylinders. Closed to form an inner cavity that matches the shape of the bearing bush 3, one connecting edge of the upper and lower tires 2, 1 is flexibly connected by a pin, and the other connecting edge is fixedly connected by a bolt; the upper and lower tires are connected by a pin. The carcass 2, 1 is respectively provided with a fixed sleeve 10, and the fixed sleeve 10 on the upper and lower carcass 2, 1 is connected together by the fixed pin 8, and another fixed sleeve 9 is set on the fixed pin 8, and the upper and lower carcass 2, 1 are connected together. The lower carcass 2, 1 can be opened and closed around the fixed pin 8; the other connecting edge of the upper and lower carcass 2, 1 is connected by bolts: a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com