Load capacity self-measuring transducer of freight vehicle

A technology of load capacity and self-measurement, which is applied in the direction of measuring devices, instruments, weighing, etc., can solve the problems of unfavorable drivers real-time observation, troubles, etc., and achieve the effects of uniformly distributed transmission, accurate measurement, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

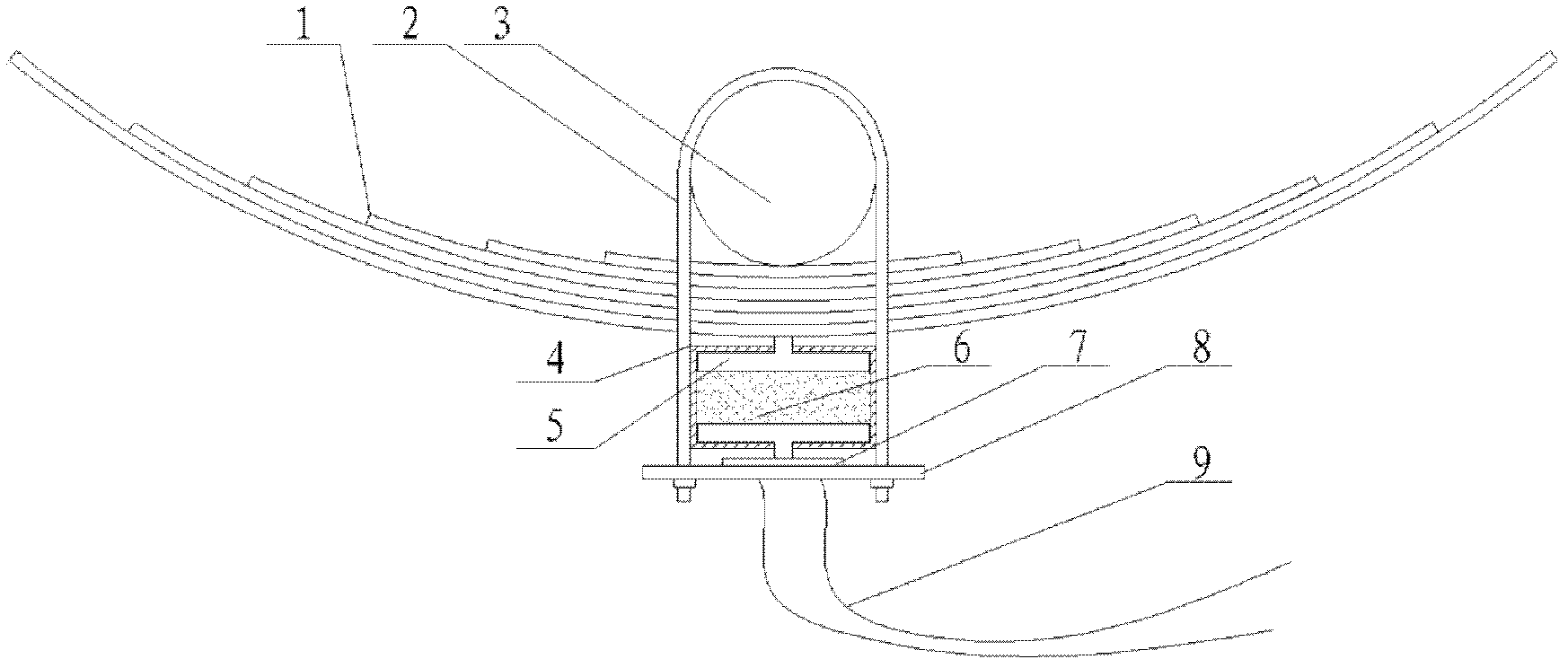

[0014] Such as figure 1 As shown, the present invention includes a sensor housing 4, a vertically symmetrical piston device 5 composed of two piston rods and two piston plates, a hydraulic medium 6 filled between the upper and lower parts of the piston device 5, and a fixed steel plate 8 and the pressure sensor 7 that converts the pressure value into an electrical signal, the middle section bypasses the axle 3 and the left and right ends pass through the fixed steel plate 8 to form an inverted U-shaped fixed steel pipe 2, and the signal output by the pressure sensor 7 is transmitted to the driver. chamber and the wire 9 finally displayed by the weight value; the upper piston rod of the piston device 5 abuts against the bottom of the leaf spring 1, and the lower piston rod end of the piston device 5 abuts against the upper surface of the pressure sensor 7, so The fixed steel pipe 2 and the fixed steel plate 8 are fastened and fixed by bolts and surround the housing 4 and the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com