Load capacity self-measuring system of freight vehicle

A technology of self-measurement and load capacity, which is applied in the field of measurement systems, can solve the problems of unfavorable drivers’ real-time observation and troubles, and achieve the effect of simple structure, accurate measurement and uniform distribution of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

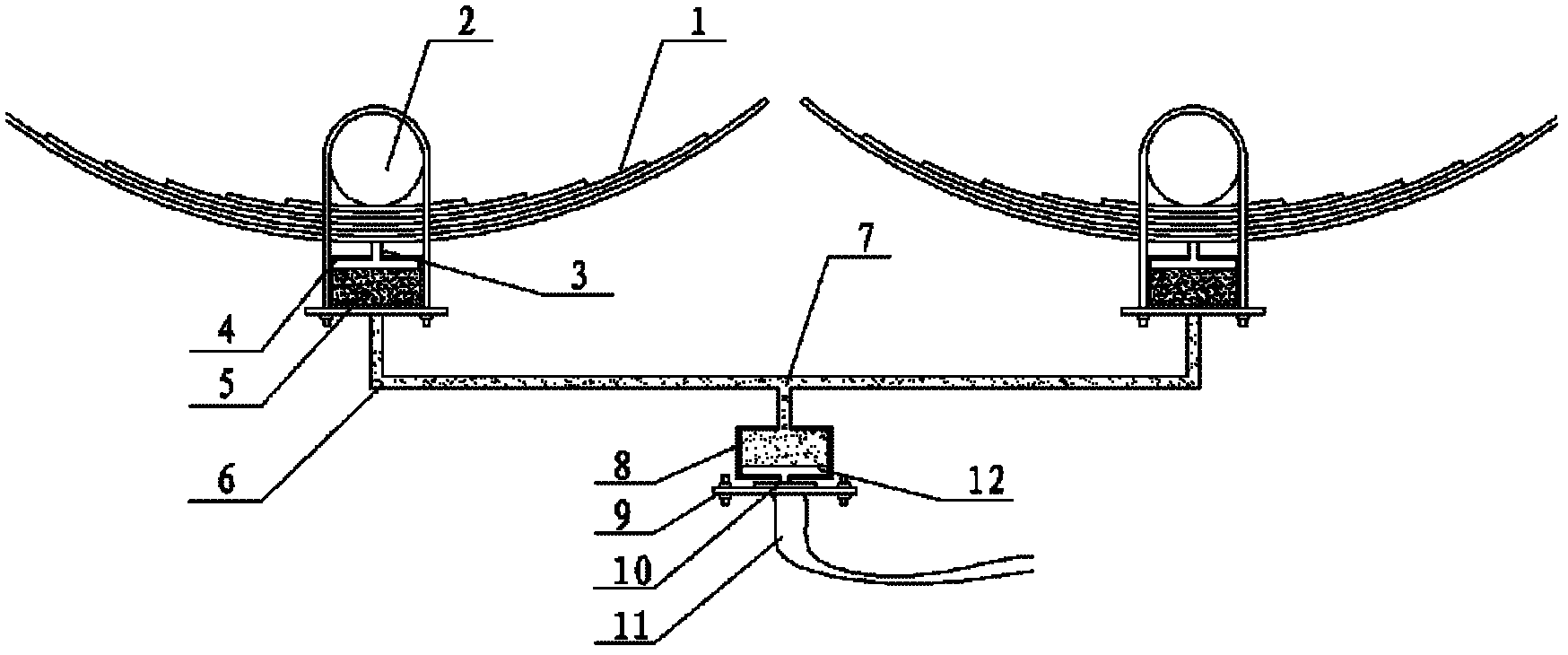

[0017] Such as figure 1 As shown, the present invention includes a self-measuring sensor device installed at the bottom of the leaf spring 1 of a freight car, a medium pipe 6 leading from the bottom of the self-measuring sensor device, a pipe connecting device 7 for sealingly connecting the ends of a plurality of medium pipes 6, The collecting device connected to the pipe connecting device 7 through the collecting pipe and the wire 11 that transmits the signal output by the collecting device to the cab and finally displayed as a weight value; the self-measurement sensor device includes a sensor housing 4, The piston rod 1 and the piston plate 1 are vertically connected to form a piston device 3 and the hydraulic medium 5 filled between the piston device 3 and the sensor housing 4; the piston rod passes through the upper wall of the sensor housing 4 and abuts against At the bottom of the leaf spring 1, the left and right ends of the piston plate are tightly attached to the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com