Method and device for correcting composite type fully automatic platform bridge deflection

A fully automatic and composite technology, applied in the direction of object supply, positioning objects, pile separation, etc., can solve the problems of cardboard damage, the sun wheel is difficult to adapt to high speed, etc., to achieve low cost, energy saving, environmental protection, automatic industrial upgrading, and avoid cardboard waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

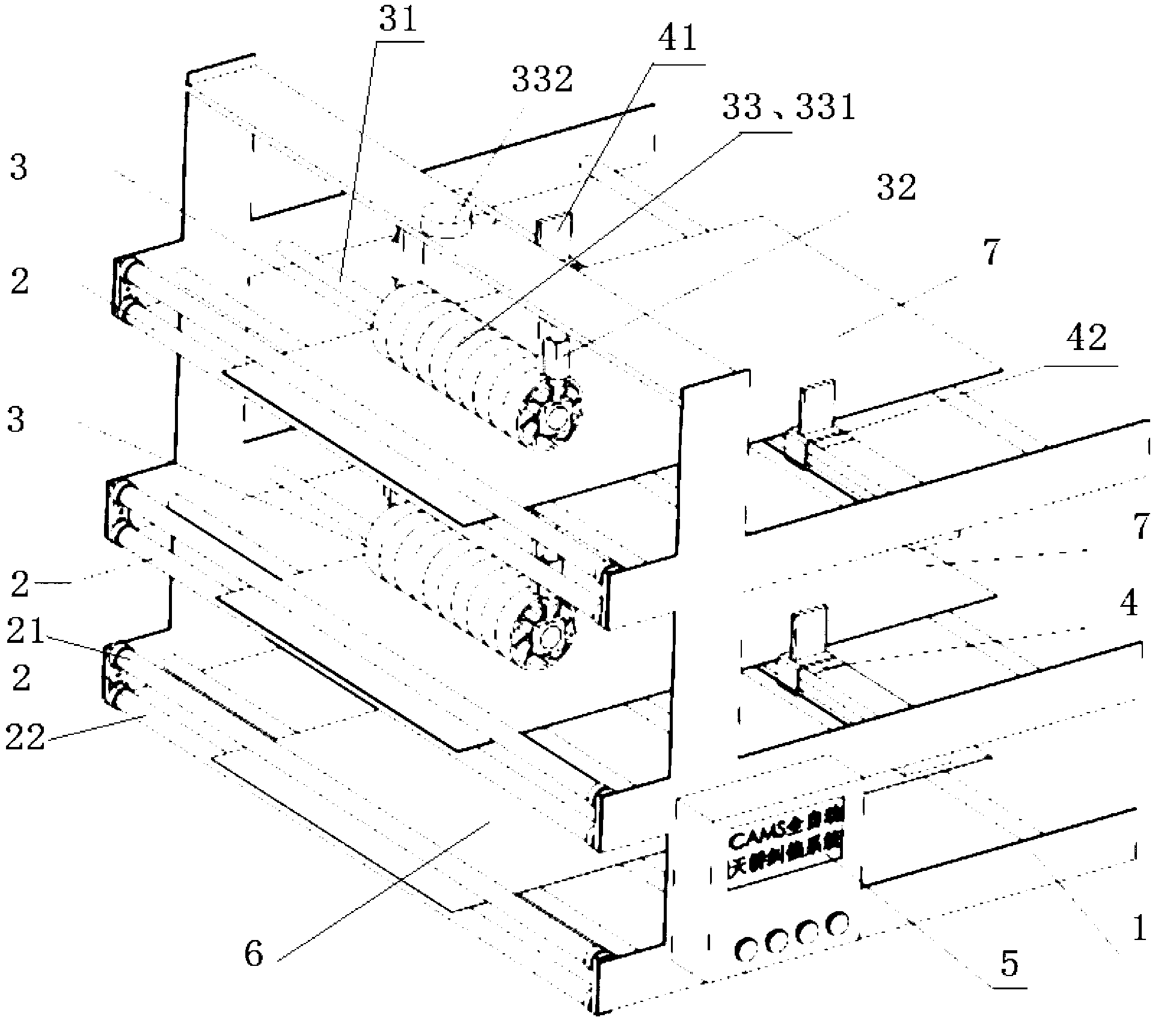

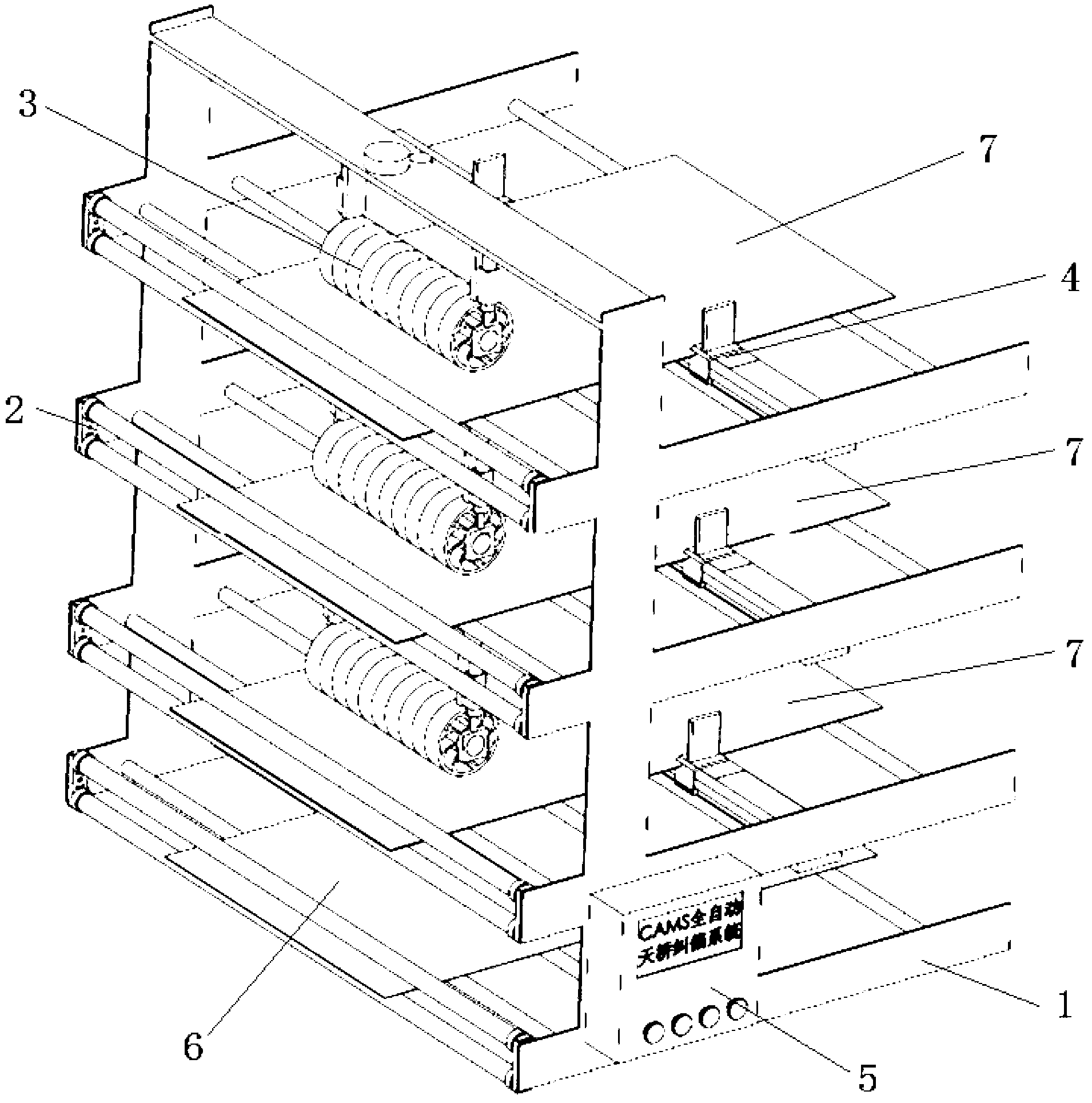

[0039] see Figure 1~Figure 4 , the compound type full-automatic method for rectifying an overpass provided by the present embodiment, it comprises the following steps:

[0040] 2) A base 1 is set, and a measuring light curtain sensing unit group, a sun gear deviation correction unit group and an automatic limit unit group are installed on the base 1; the measuring light curtain sensing unit group includes two groups or More than two groups of measurement light curtain sensing mechanisms 2, which are composed of correspondingly arranged transmitting ends 21 and receiving ends 22; the sun gear deviation correction unit group includes two or more than two groups of sun gear deviation correction mechanisms 3, which are composed of fixed frame 31, lifting device 32 and correction device 33; the automatic limit unit group includes two or more sets of automatic limit mechanisms 4, which are driven by the corresponding left and right limit stoppers 41, 42 and limit The device is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com