Method for preparing oil in auxiliary cold pressing manner by solid-state fermentation of oil crops by two steps via aspergillus oryzae

A technology of oil crops and solid-state fermentation, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems affecting the quality of oil extraction effect, and achieve the effect of improving oil yield by cold pressing, increasing oil extraction rate, and effective decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

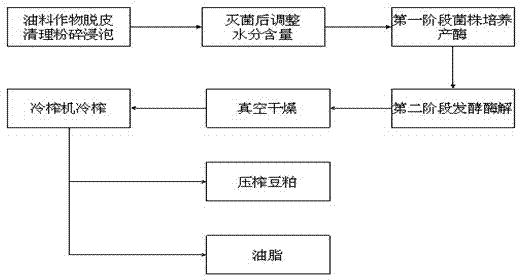

[0018] Material treatment: After peeling, cleaning, crushing and soaking oil crops, put them in an autoclave for high-pressure sterilization. The sterilization temperature is 110°C-130°C, and the sterilization time is 10min-30min, or microwave sterilization, power Sterilize at 700w for 5-10min.

[0019] Moisture adjustment: Use sterile water to adjust the moisture content of the material to 20%-40% of its dry weight, and then add 5%-15% (w / w) of the logarithmic phase of Aspergillus oryzae seed liquid or its spore suspension.

[0020] Bacterial enzyme production: in the first stage, bacterial growth and enzyme production are cultivated at 25°C-40°C for 24h-72h.

[0021] Enzymolysis: The temperature of the second stage of enzymolysis is 30°C-50°C, and the time of enzymolysis is 8h-48h after the first stage.

[0022] Vacuum drying: the vacuum dryer controls the temperature at 30°C to 50°C to dry the fermented material and keep its moisture content at 4%—10%

[0023] Cold pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com