Pet food production powder mixing device adopting equipartition and swinging principle

A pet food, principle technology, applied in the application, feed, food science and other directions, can solve the problems such as the nutrient ratio cannot be uniform and cannot be more refined, and achieve the effect of increasing the mixing range, ensuring quality and avoiding caking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

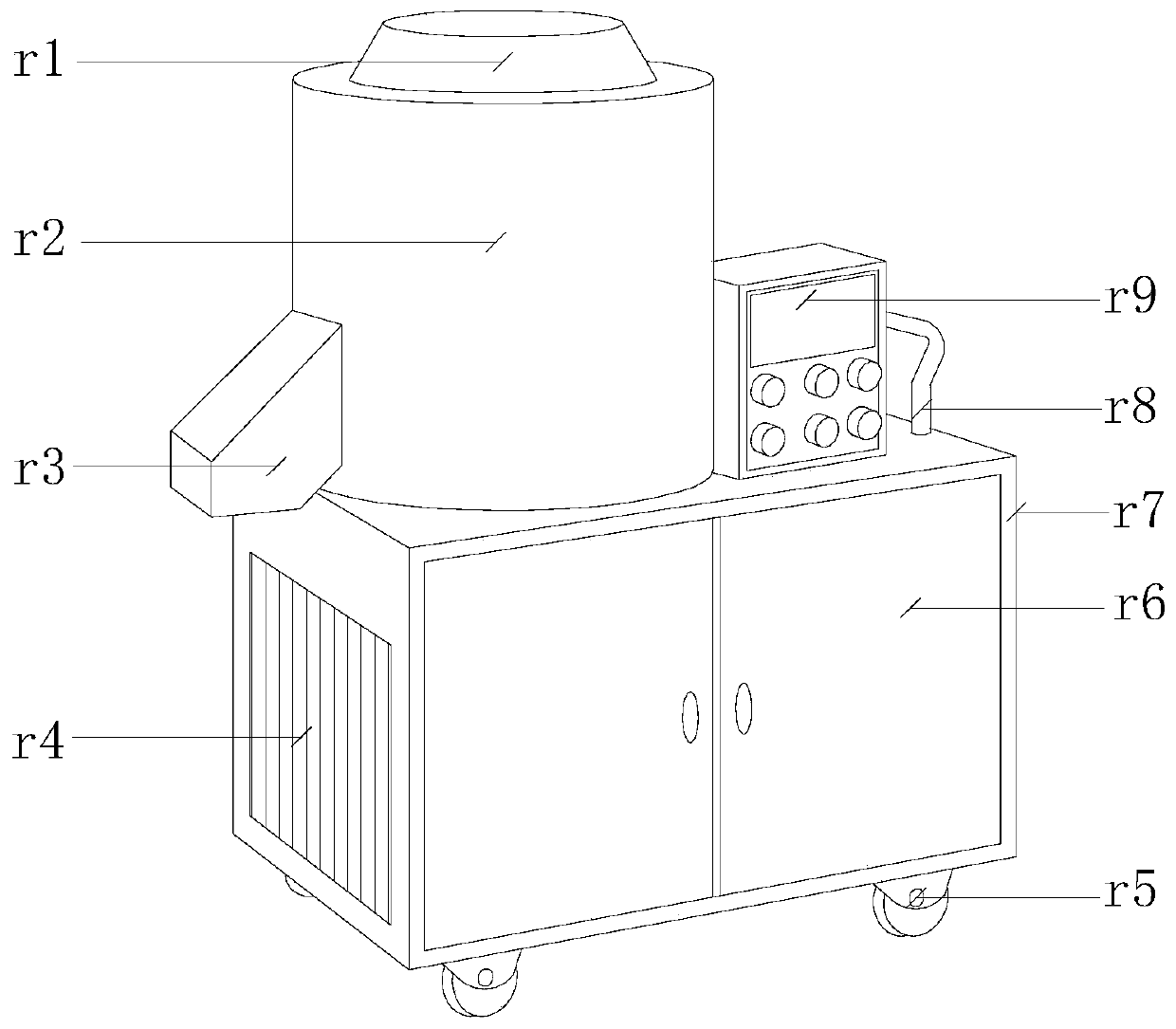

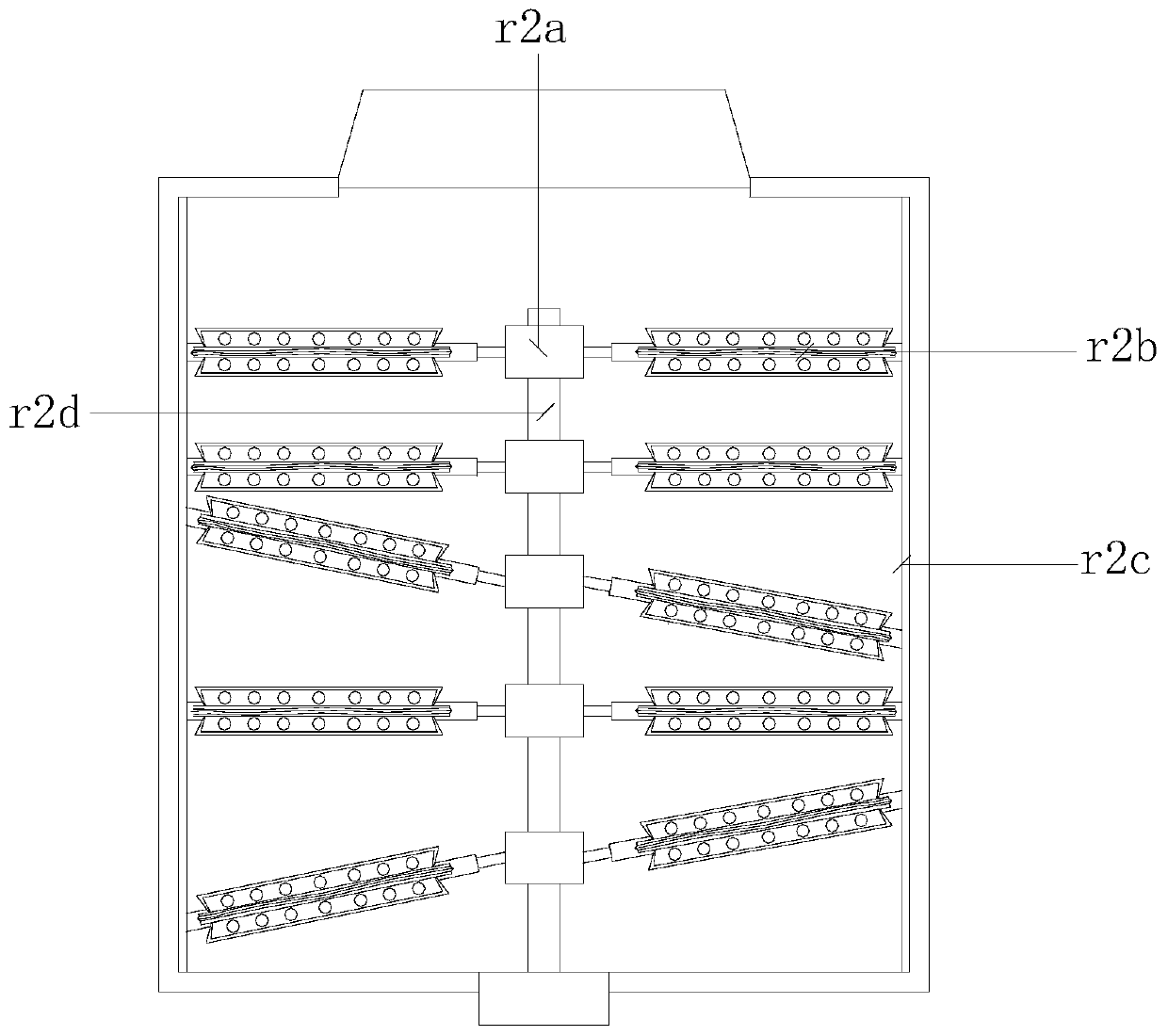

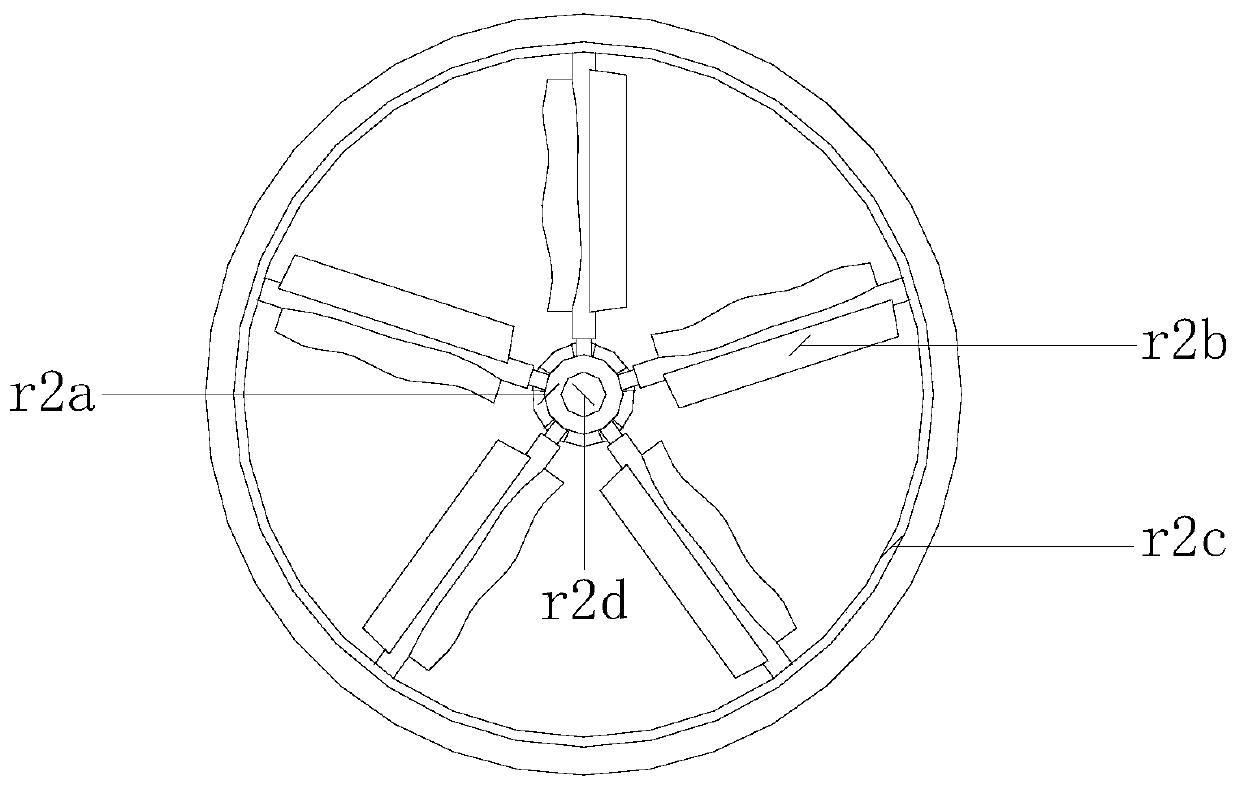

[0030] see Figure 1-Figure 7 , the present invention provides a powder mixing device for pet food production that adopts the principle of evenly distributing and swinging materials. The processing host r7, the moving handle r8, and the controller r9. There are four moving wheels r5, which are evenly and equidistantly distributed on the four ends of the bottom of the processing host r7 by fastening. The left side of the processing host r7 is provided with a cooling groove r4, there are two inspection doors r6, and they are installed on the front end of the preparation warehouse r2 by buckling. The right end of the top of the host r7 is provided with a controller r9, the mobile handle r8 is installed on the top right side of the processing host r7 by welding, the discharge port r3 is installed on the lower left side of the preparation bin r2 by embedding, and the feed port r1 is set on the top of the preparation bin r2, and is an integrated structure. The raw materials are pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com