Method achieving transformation of time and depth through change in weight of downhole tool

A downhole instrument and weight change technology, which is applied in measurement, earthwork drilling, borehole/well components, etc., can solve the problems of cumbersome data volume, many equipment and personnel, low efficiency and accuracy, etc., and achieve convenient operation, instrument The effect of simple equipment and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

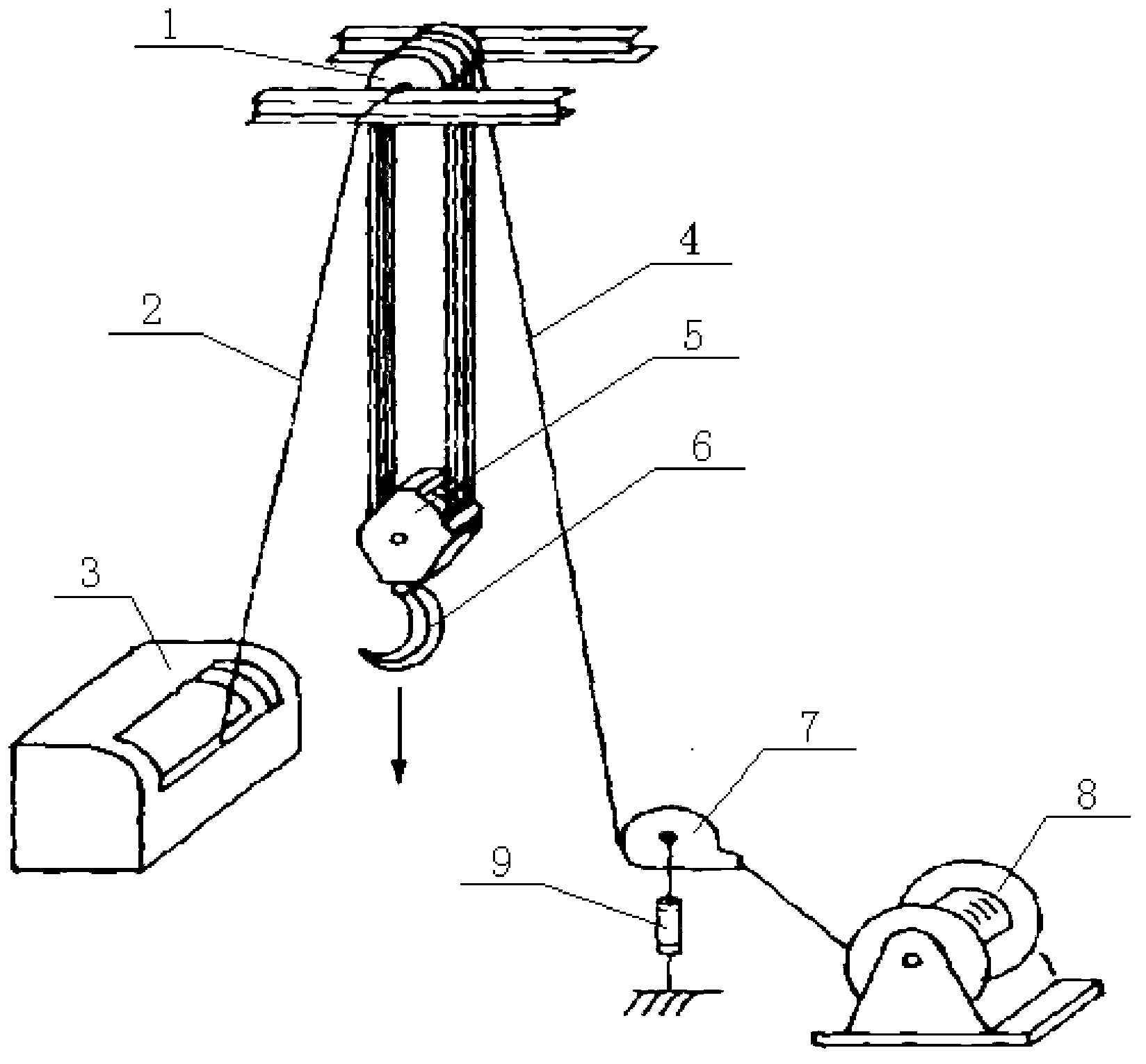

[0030] The method of realizing the conversion of time and depth through the weight change of the downhole tool and tool firstly sets up the surface tool, and then performs the downhole operation of the tool, such as figure 1 Shown is a schematic diagram of the logging device structure. A traveling block 5 is suspended under the roller on the crown block 1 at the wellhead, and a hook 6 is installed under the traveling block 5. The winch 3 on the ground is connected to the crown block 1 through a wire rope 2. The upper roller, the other side of the roller of the crane 1 is connected with a dead rope 4, the lower end of the dead rope 4 is connected to the ground roller 8, and a fixed bracket for installing the hook load tension sensor 9 is installed on the lower part of the dead rope 4 7. The lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com